Ring mixed cavity solid slat laser with back wave suppression

A slab laser and hybrid cavity technology, which is applied to lasers, laser parts, phonon exciters, etc., can solve the problems of reducing the final laser output energy, not being able to fully extract pump energy, and not being able to eliminate gain distribution, etc., to overcome Influence of reverse wave, improvement of heat conduction performance, effect of beam homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

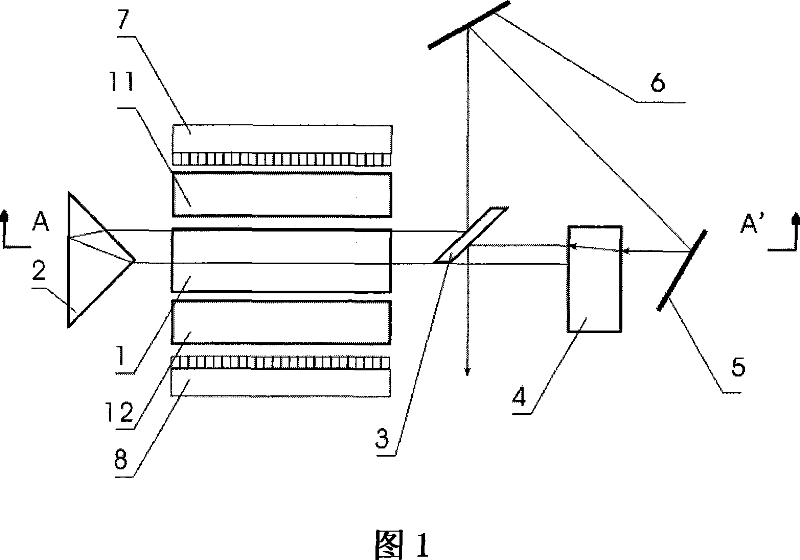

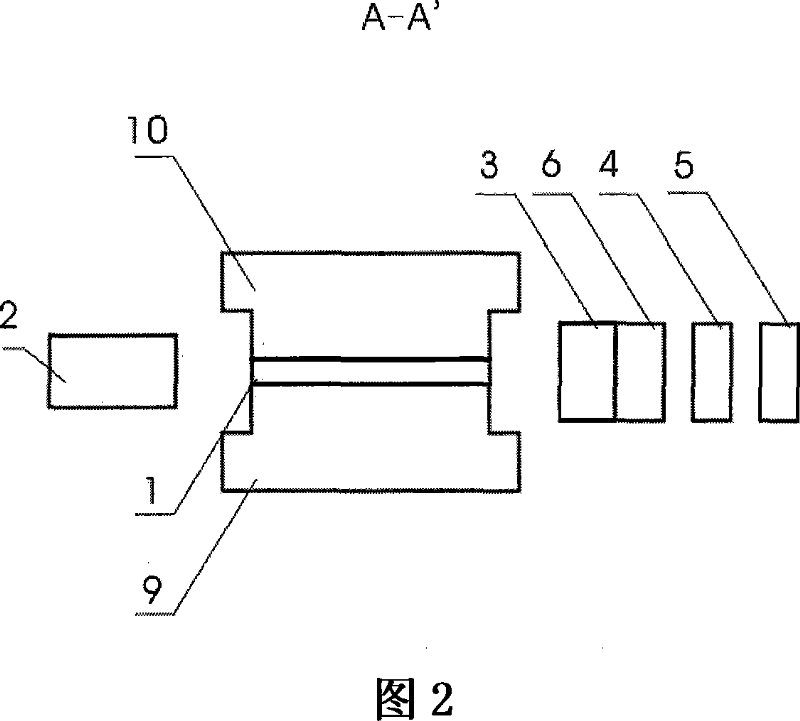

[0019] Referring to the accompanying drawings, Fig. 1 is a top view of a preferred embodiment of the laser of the present invention; Fig. 2 is a cross-sectional view of A-A' of Fig. 1 . As can be seen from the figure, the composition of the annular mixing cavity solid slab laser with reverse wave suppression in the present invention is: with the optical axis of the laser as the center line, a triangular prism 2, a slab gain medium 1, a scraper mirror 3, and a beam expander are placed in sequence. System 4, the first total reflection cavity mirror 5, the scraper mirror 3, the first total reflection cavity mirror 5 and the second total reflection cavity mirror 6 are all placed at a certain angle with the optical axis, so that through the scraper mirror 3 , the second total re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com