A. C. brushless double-fed motor

A doubly-fed motor, winding type technology, applied in the direction of asynchronous induction motors, electromechanical devices, electrical components, etc., can solve the problems of large volume, performance index gap, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

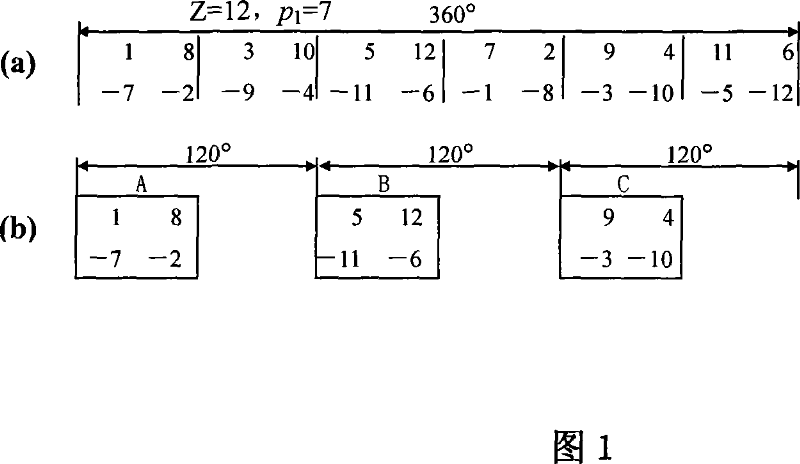

[0036] The present invention is further described below with embodiment. Motor rotor, the number of pole pairs of its power winding is p 1 = 7, the rotor winding is required to be a three-phase symmetrical regular 60° phase-belt connection winding, at this time it can be considered to select p 2 =5, according to the relationship p 1 =Z-p 2 , select the number of rotor slots as Z=p 1 +p 2 =12.

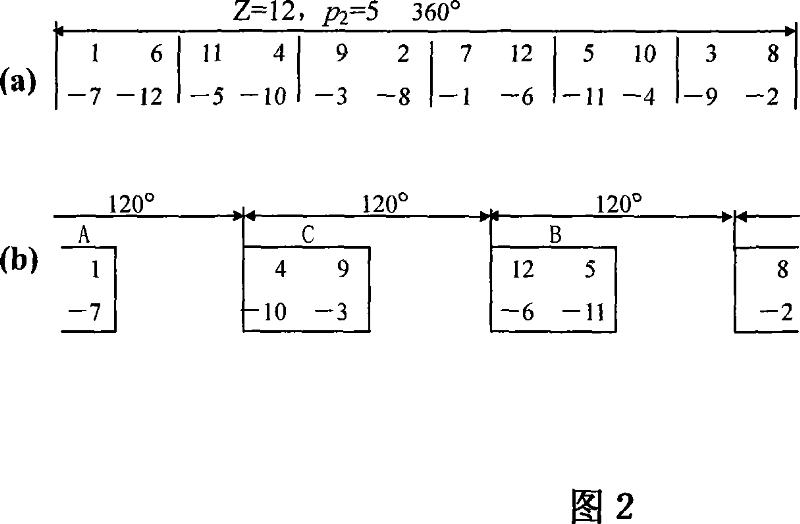

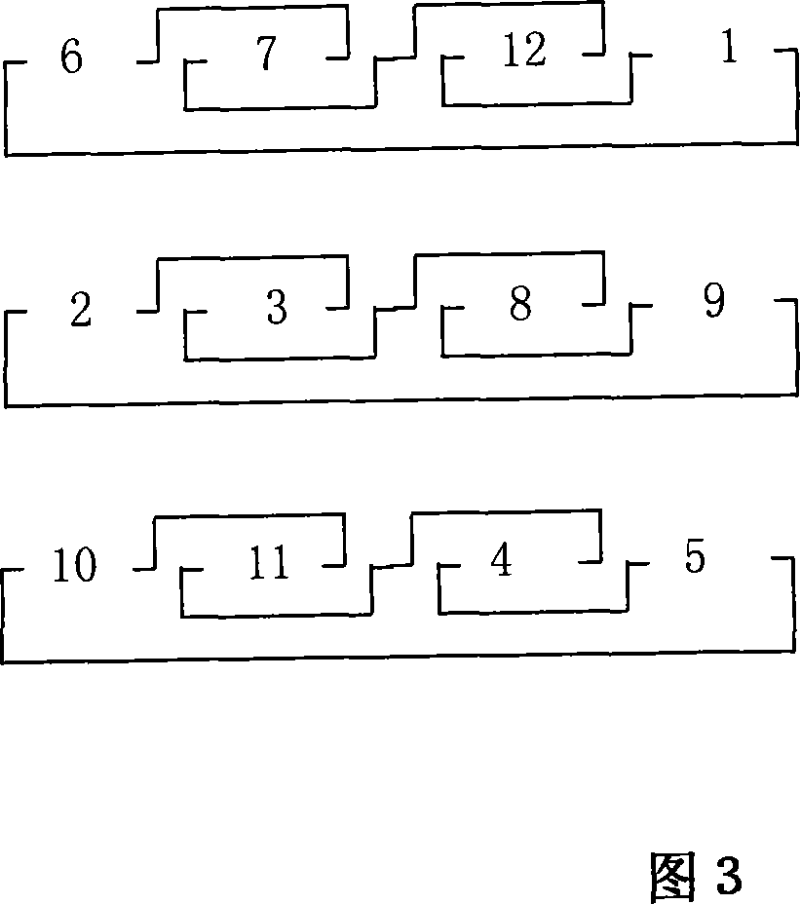

[0037] For Z=12, p 1 = 7, if it is required to obtain a three-phase normal 60° phase belt winding, the slot number phase diagram can be drawn first, as shown in Figure 1(a), so that the three-phase slot number distribution can be determined as shown in Figure 1(b) , it can be seen that for p 1 =7 is the three-phase regular 60° phase belt winding, the winding distribution coefficient is cos15°=0.9659; and for p 2 =5, see Figure 2, Figure 2(a) is p 1 = 5 slot number phase diagram, Fig. 2(b) is p 1 =The three-phase slot number determined at 7 and then press p 2 =5 phase redistri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com