System for the gas and liquid discharging and breathing system without oxygen for cylinder type juice extractor

An anaerobic respiration and juice extractor technology, which is applied in household machinery for filtering food, application, juice extraction, etc., can solve the problems of aggravating juice browning, maintain purity, reduce biological and physical pollution, and reduce oxidative browning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

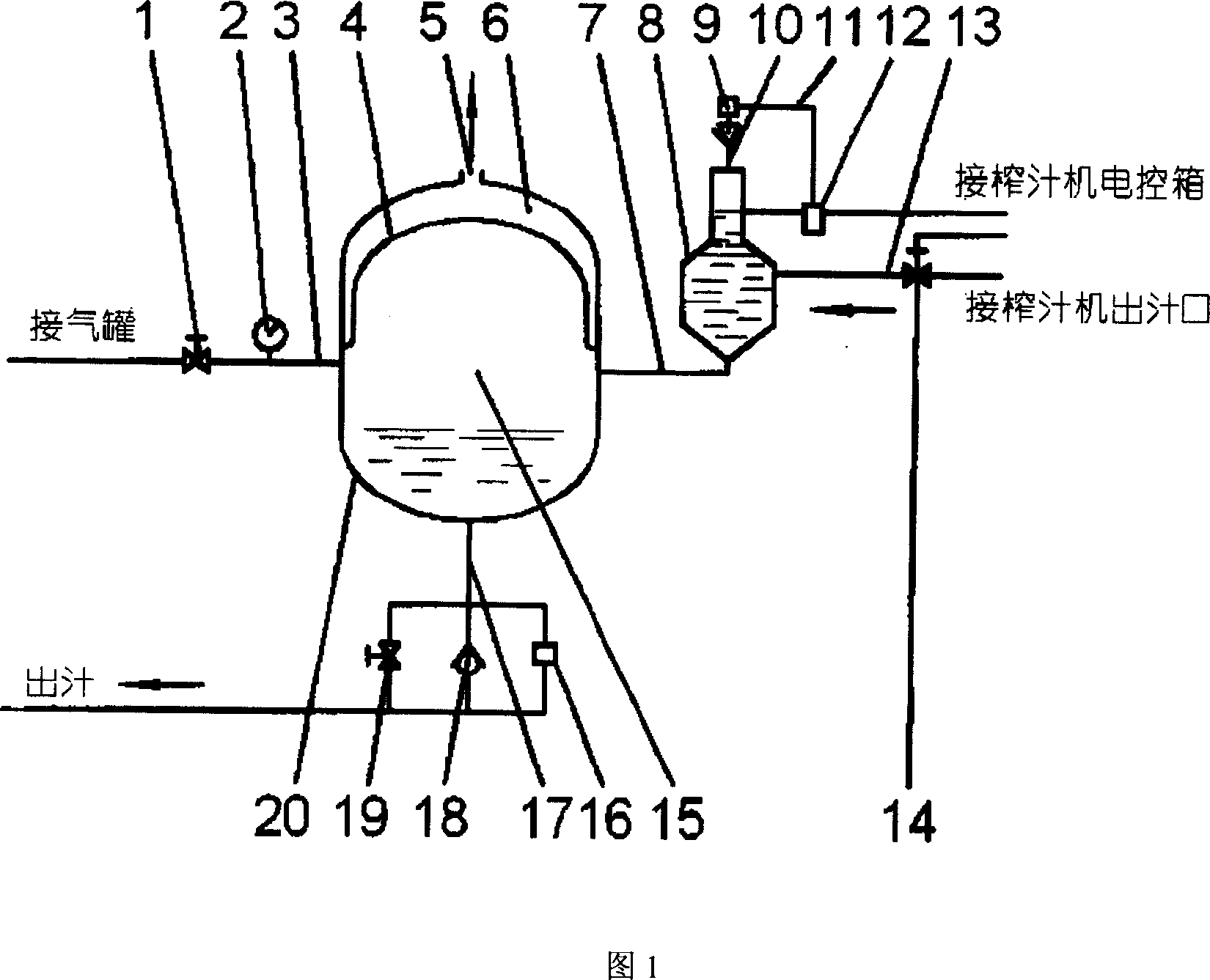

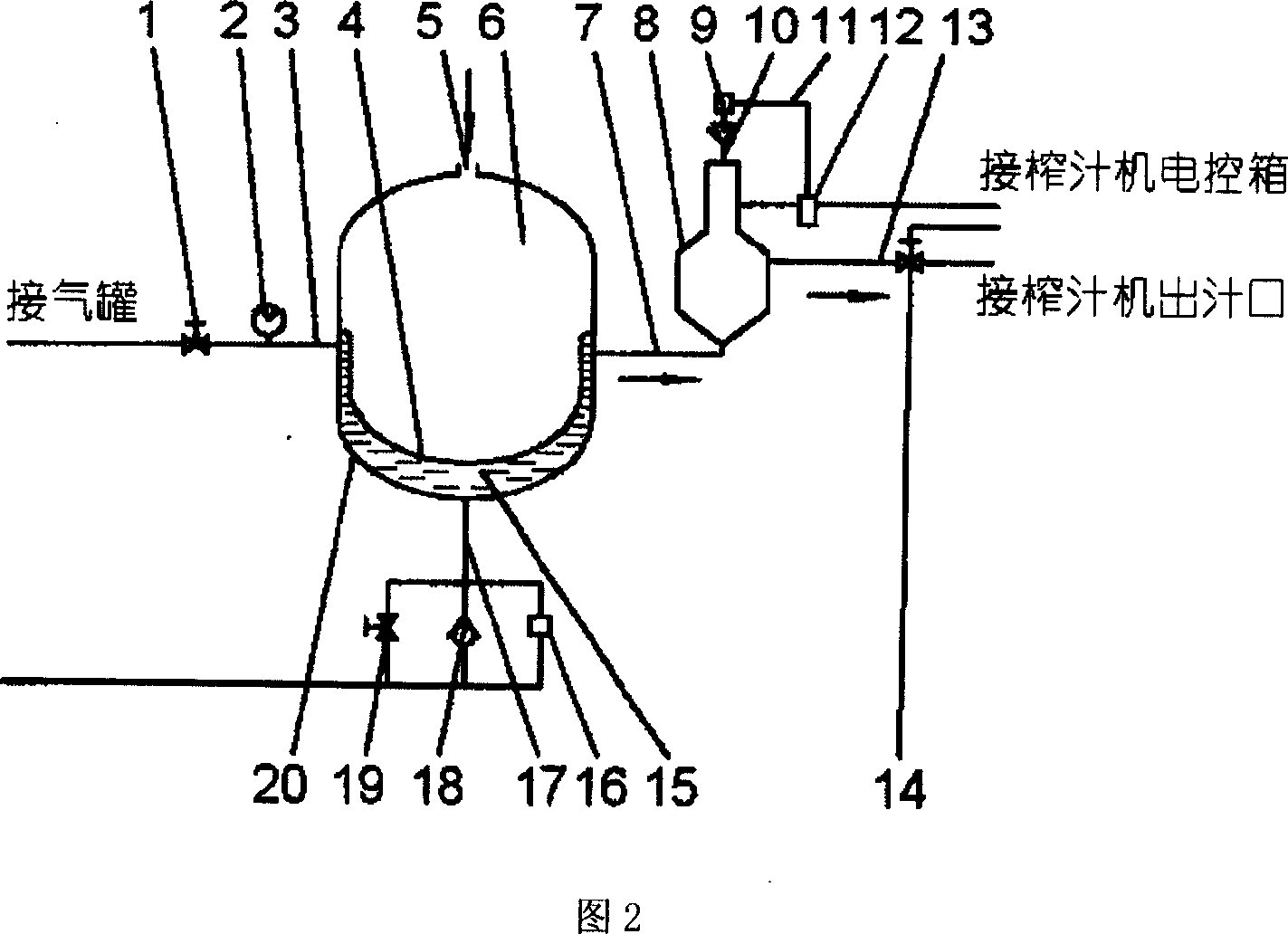

[0014] The invention provides an anaerobic respiration system for a cylinder juice extractor, which is used as an auxiliary system for degassing, discharging juice and anaerobic respiration of the cylinder juice extractor. The schematic diagram of the anaerobic respiration system of the barrel juice extractor shown in FIG. 1 includes an air separation tank 8 connected in series with a connecting pipe 7 and an air storage tank 20 filled with inert gas. The air release pipe 10 on the top of the separation tank 8 is connected to the time sequence liquid level control air release valve 9, the neck is equipped with a liquid level sensor 12, the liquid inlet pipe 13 on the top of the tank body is connected to the time sequence control feed valve 14, and the bottom of the separation tank 8 is connected to The tube 7 is connected to the gas storage tank 20, and a flexible diaphragm 4 is fixed inside the gas storage tank 20, which divides the inner chamber of the gas storage tank 20 int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com