Device and method for the automatic replacing of the paper liner plate

An automatic replacement and paper backing technology, which is applied in stacking receiving devices, transportation and packaging, metal processing, etc., can solve the problems of easy side slipping and scattering of paper sheets, achieve simplified structure, reduce complexity, and replace coded paper The simple effect of the pallet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment the present invention is described in further detail:

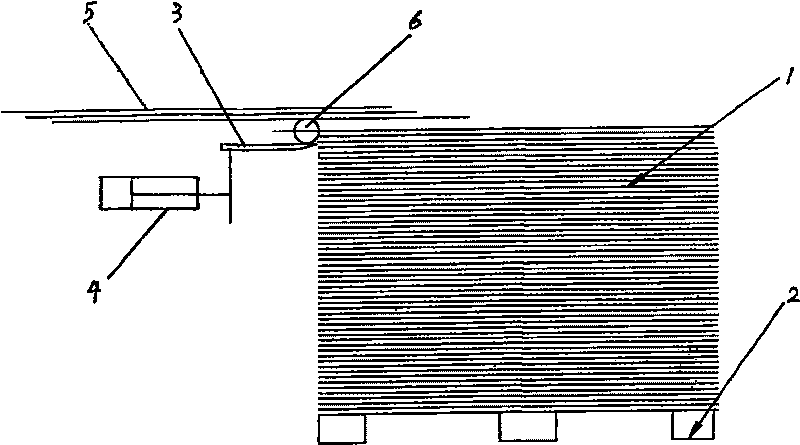

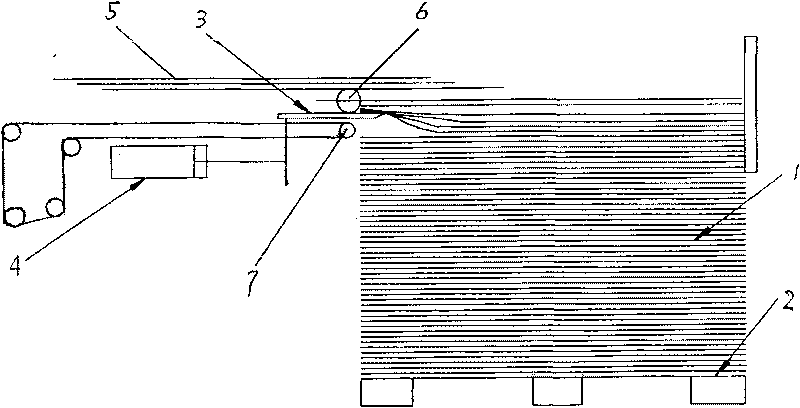

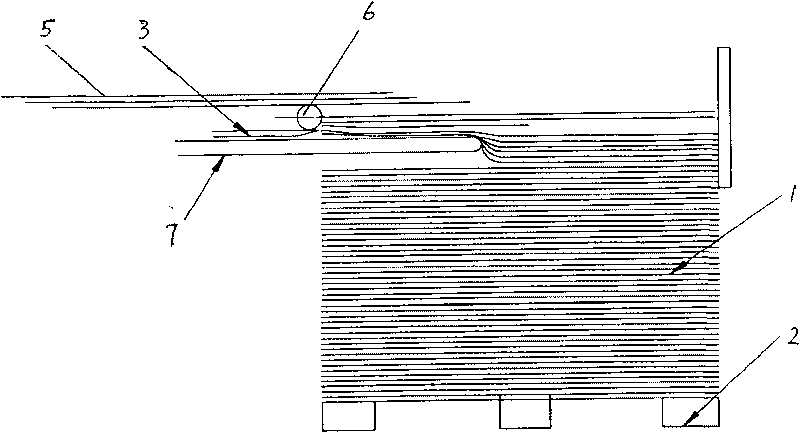

[0033] see Figure 1-Figure 7 , an embodiment of an automatic paper backing device for a paper cutter of the present invention, comprising a pallet for stacking cut paper sheets 5, a conveyor belt 6 for transporting the cut paper sheets 5 to the pallet, and a predetermined amount of paper that can be inserted into the pallet. A sheet-like separator 3 forming a gap between the stack 1 of pages and the following sheet 5, the sheet-like separator 3 is arranged horizontally and connected to the rod of a computer-controlled cylinder 4; The auxiliary pallet 7 in the paper gap, the surface of the auxiliary pallet 7 is an annular belt that can rotate, and the annular belt is made of rubber belt and cloth; a finger-shaped clamping hook 8 is set below the auxiliary pallet 7, and the finger The shape clamping hook 8 is connected with a rodless cylinder 9 controlled by a computer....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com