Minitype caterpillar track

A tracked vehicle and miniature technology, which is applied to tracked vehicles, motor vehicles, transportation and packaging, etc., can solve the problem of not being able to replace the work of load-bearing wheels, and achieve the effect of simplifying the structure, increasing the fun, and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the embodiments of the accompanying drawings.

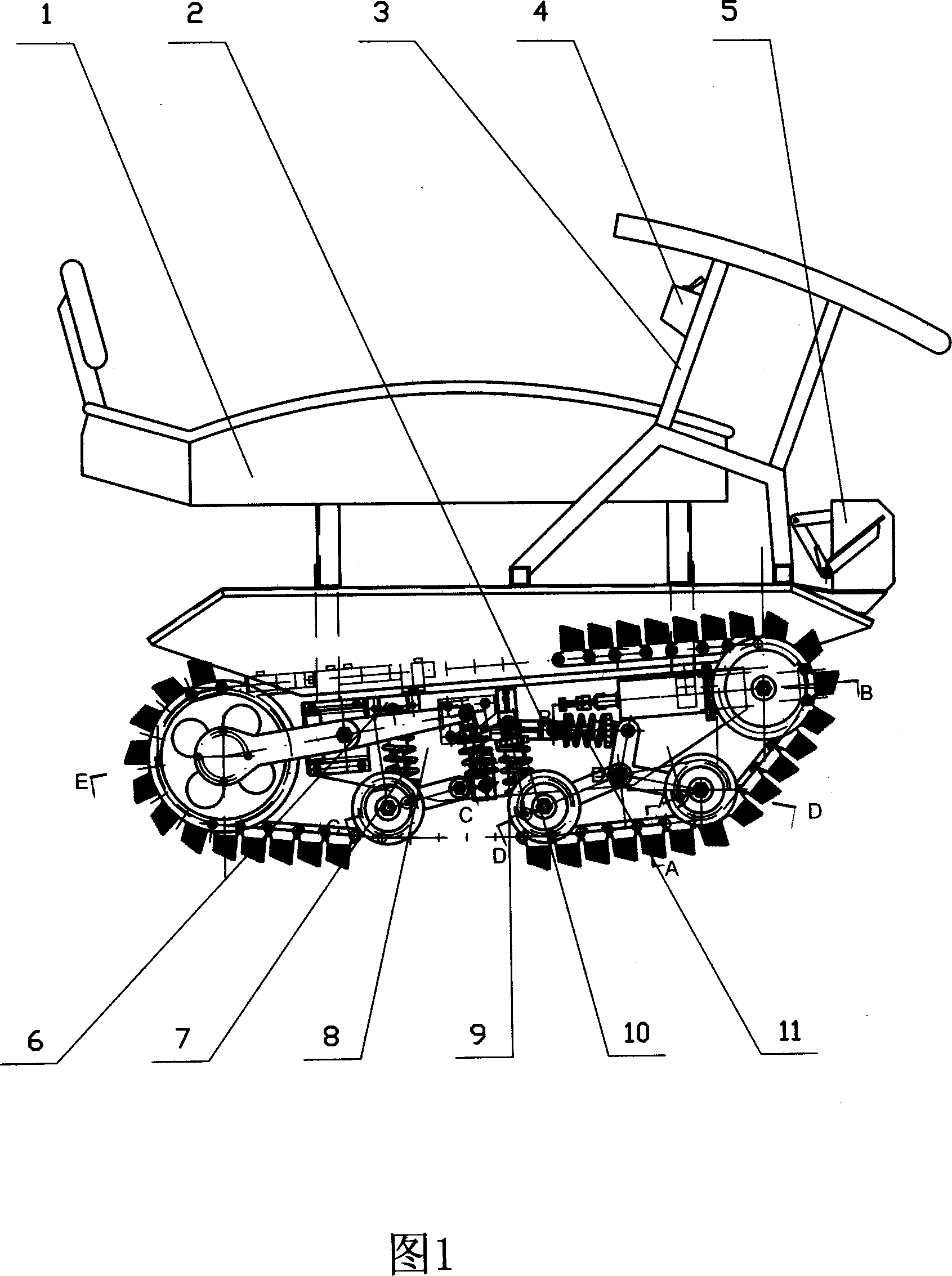

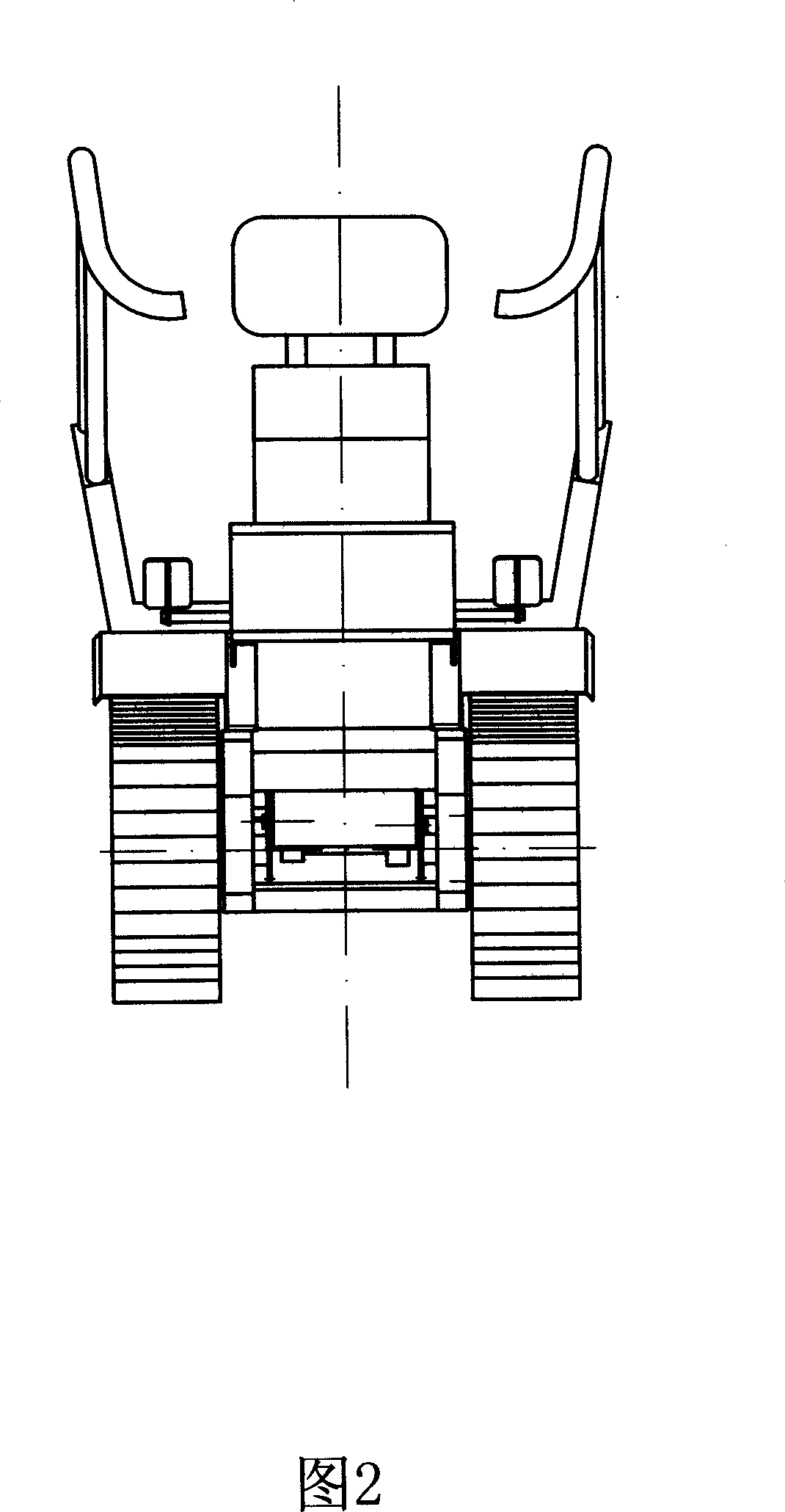

[0036] As shown in Figure 1, the miniature crawler vehicle is made up of crawler walking chassis 8, seat 1, handrail 3 and operating device 4,5.

[0037] Above-mentioned crawler belt running chassis 8 is made up of underframe, crawler belt, inducer train, bearing train, driving train.

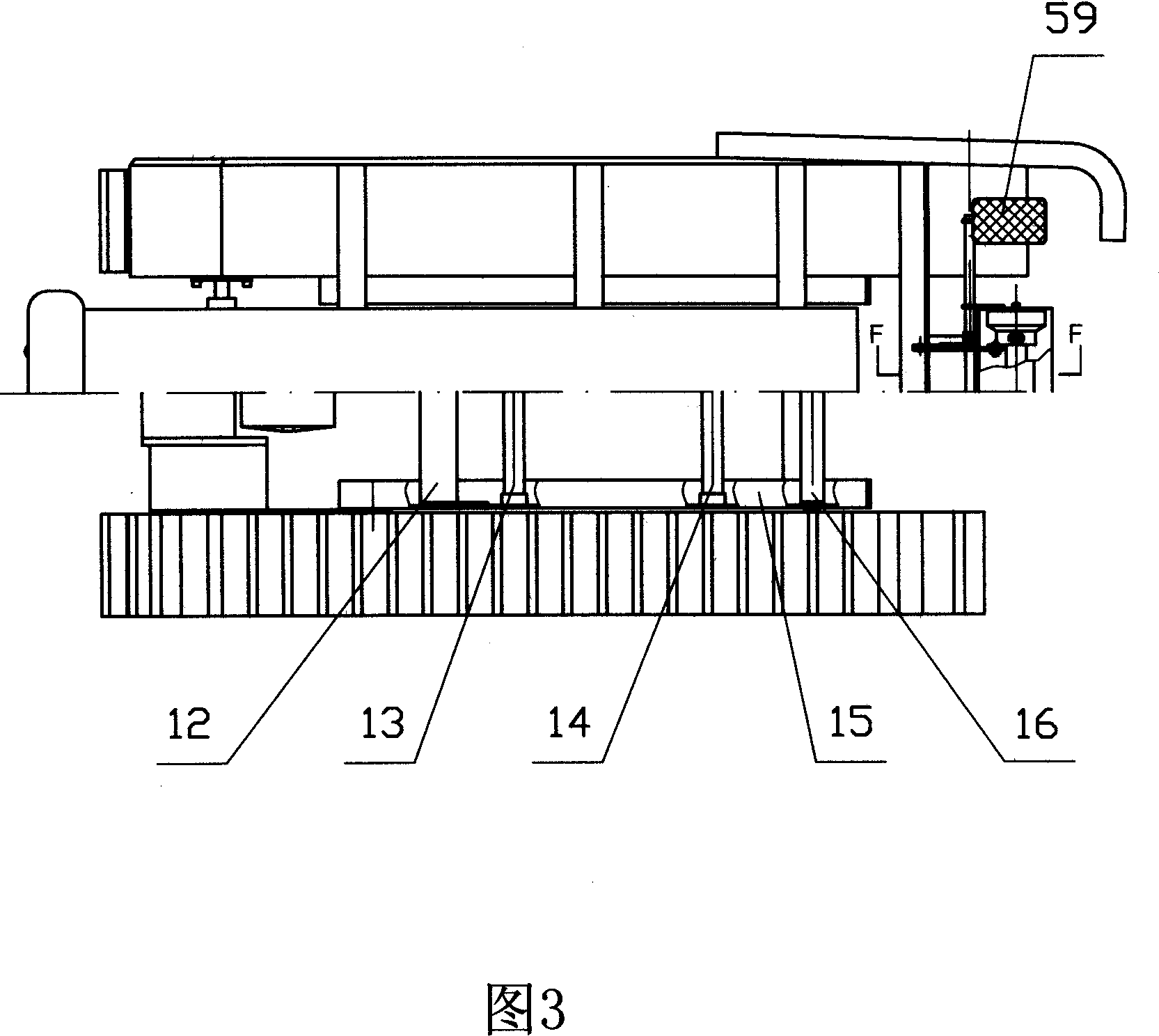

[0038] Underframe as shown in Figure 3, its wallboard 15 is supported by front crossbeam 16, rear crossbeam 12, and two bottom beams 13,14 ends have screw holes, are used for bearing wheel support fulcrum shaft 35,37 (seeing Fig. 6, 7) Penetrate the wallboard 15 and fasten it, and the wallboard 15 is provided with a long hole 68 for installing the induction wheel frame.

[0039] As shown in Figure 4, the conveyor chain 18 with bent ears is connected to the grooved track shoe 17 with fasteners 19. There are track shoulders 20 on both sides of the track shoe 17, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com