Movable calcium sulfale floor block

A technology of access floor and calcium sulfate, which is applied in the direction of floors, buildings, building structures, etc., can solve the problems of easy deformation, low flatness, and consumption of metal resources, etc., and achieve good sound insulation and fire prevention effects, high load strength, and easy installation. The effect achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

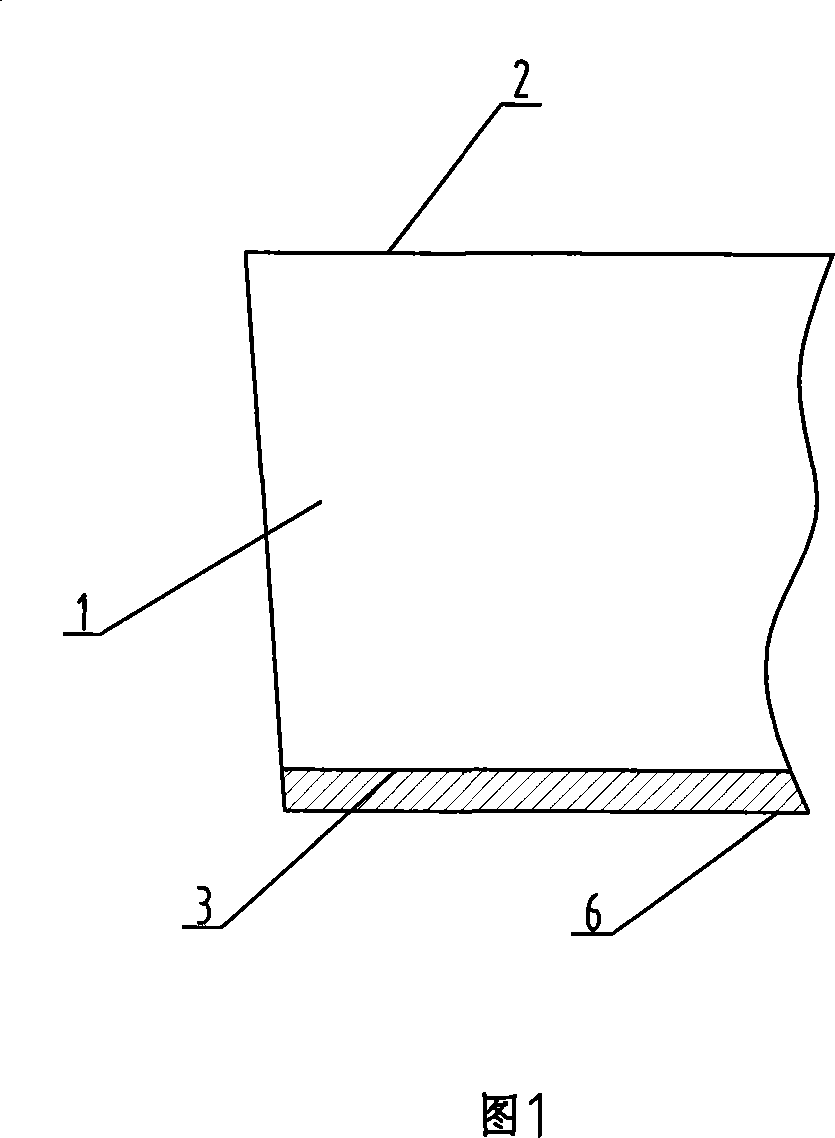

[0023] Embodiment 1: Refer to FIG. 1 . 1 in the figure is a cuboid-like substrate 1 mainly made of calcium sulfate material. The raised floor products in reality generally have the area of the upper surface 2 slightly larger than the lower surface 3 (also known as the bottom surface on the market). 4 is the side, and there are four sides, on the lower surface 3, there is a lower surface pasting layer 6 made of galvanized steel plate (mainly for improving the intensity of the raised floor).

Embodiment approach 2

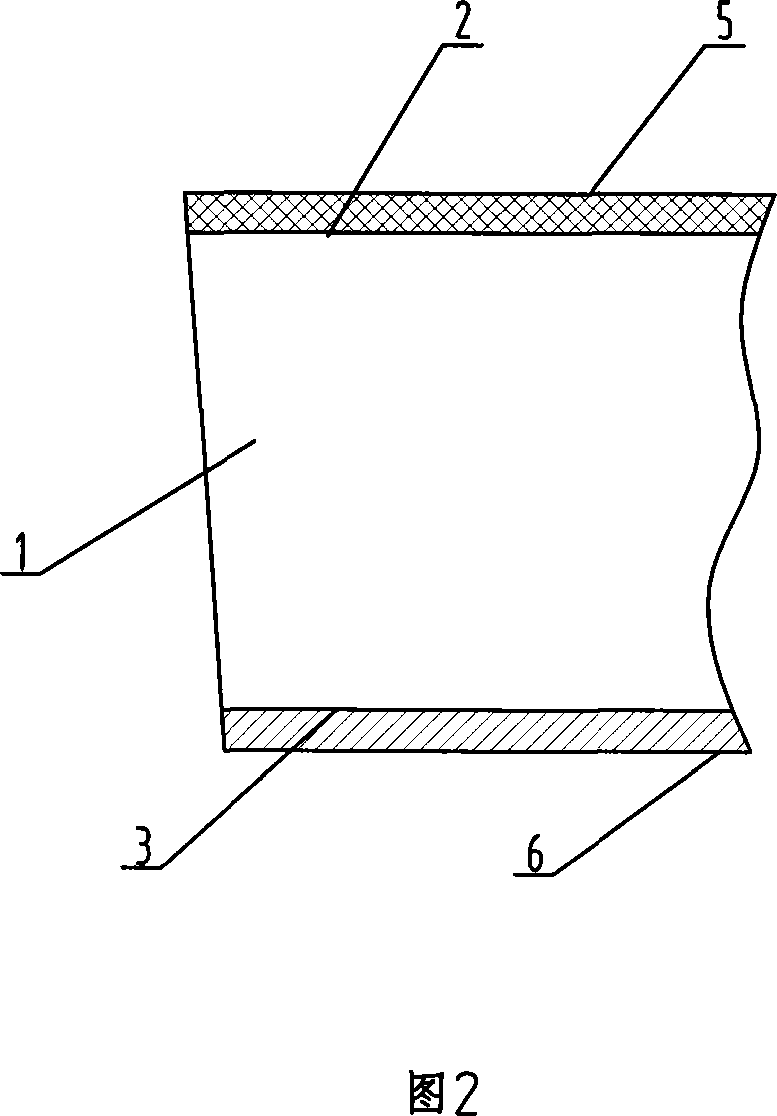

[0024] Embodiment 2: Refer to FIG. 2 . The difference from the first embodiment is that the upper surface 2 is pasted with an upper surface sticker 5 in this embodiment. According to the actual situation or user requirements, the upper surface can be laminated with galvanized steel sheet, PVC laminate, wood laminate or HPL laminate.

Embodiment approach 3

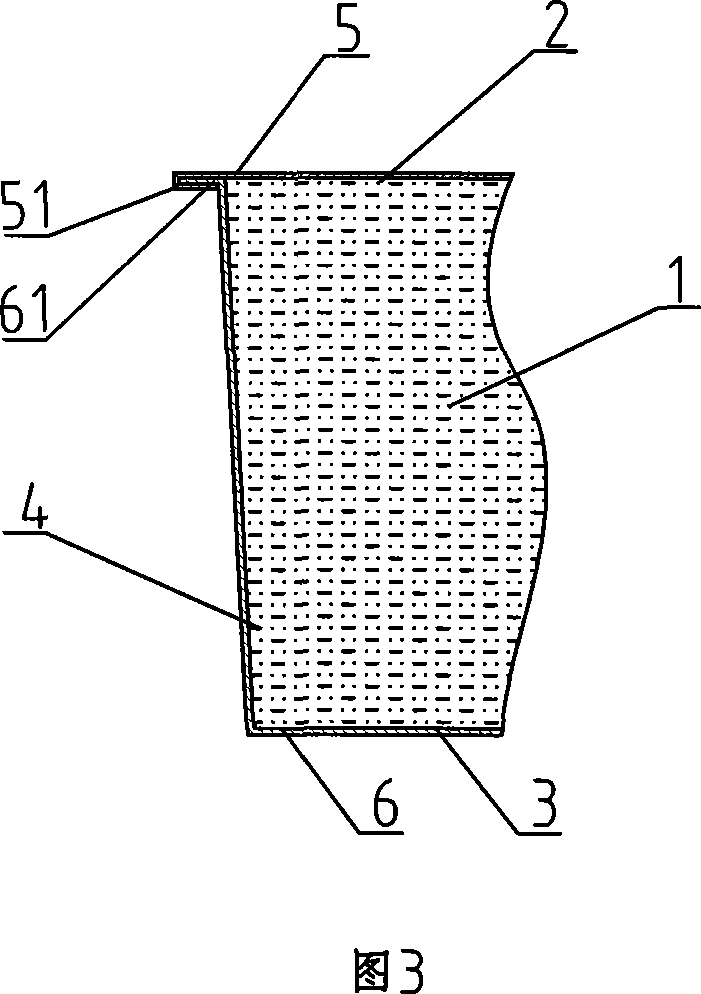

[0025] Embodiment 3: Refer to FIG. 3 . Both the upper surface 2 and the lower surface 3 of the substrate 1 are pasted with an upper surface coating 5 and a lower surface coating 6 made of galvanized steel sheets. The lower surface layer 6 is folded toward and close to the side surface 4 and extends to the upper surface 2, and there is a lower surface hem 61 outward along the upper surface 2 plane direction at the upper surface 2, and the upper surface layer 5 is along the upper surface plane direction Extend outwards, and then fold to the side 4 in the opposite direction to form the upper surface hem 51 , the lower surface hem 61 is snapped between the outwardly extending part of the upper surface veneer 5 and the upper surface hem 51 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com