Improved finned heat sink with composite steel-aluminium pins

A steel-aluminum composite and radiator technology, applied in heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc. Enhance the effect of heat conduction, improve the yield, and reduce the effect of matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

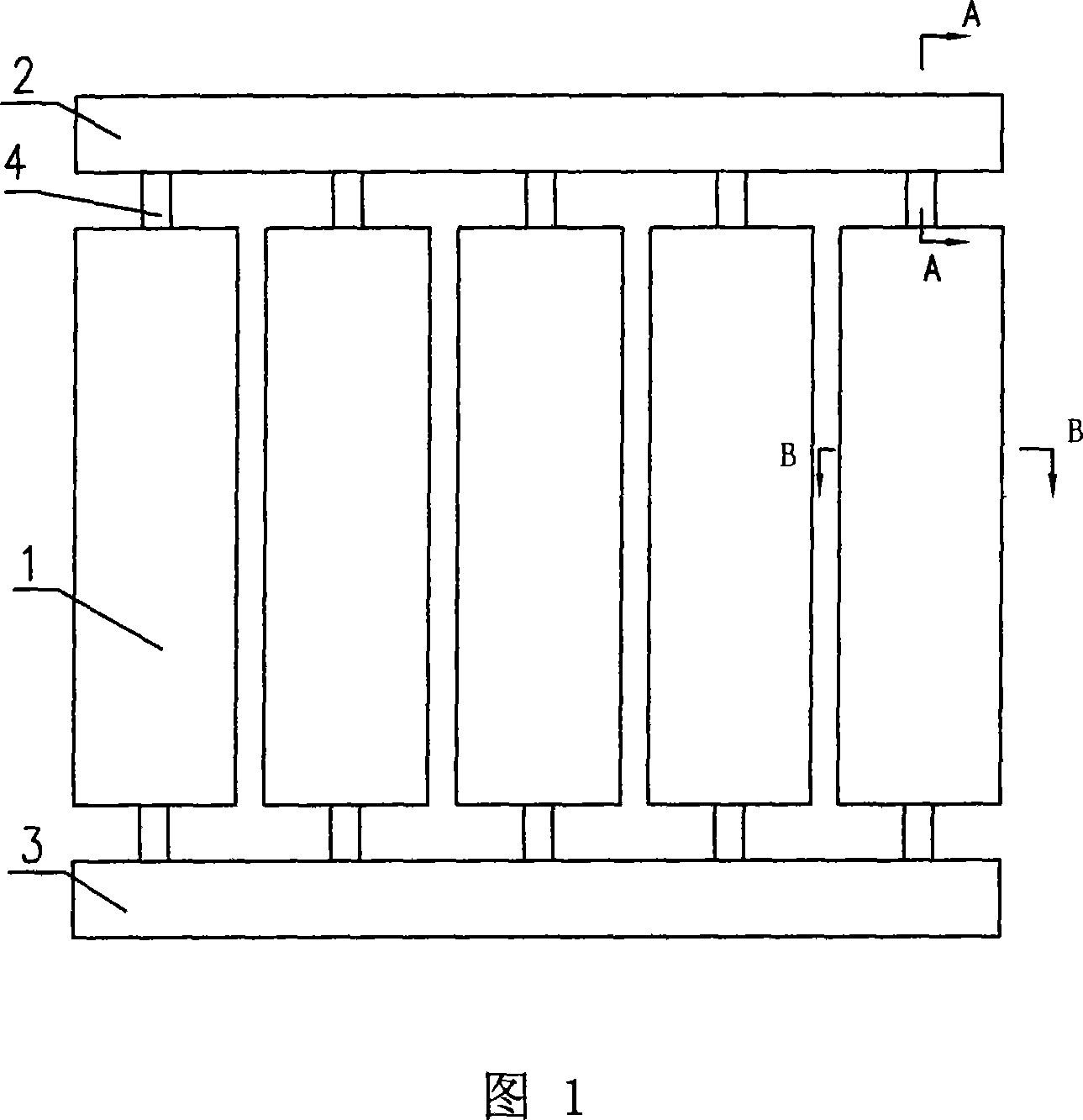

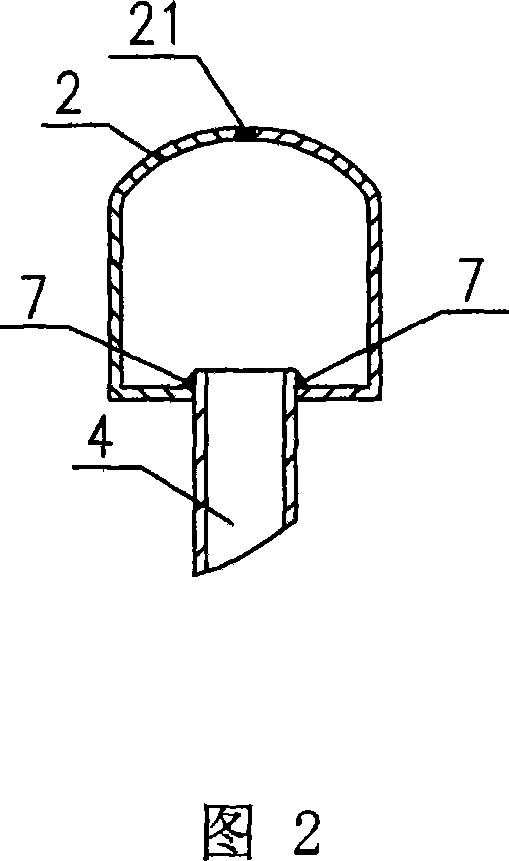

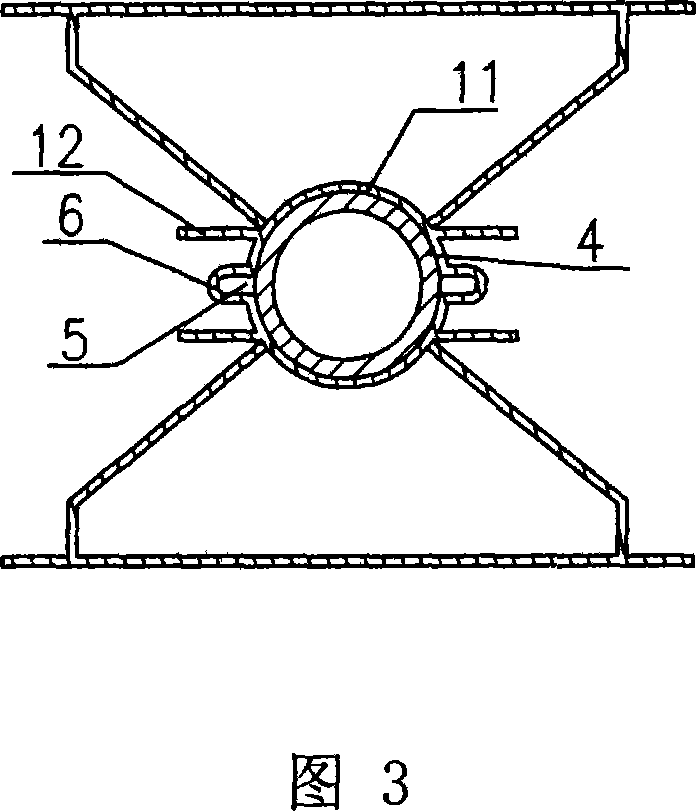

[0014] As shown in Figures 1 and 3, the improved steel-aluminum composite column fin radiator includes a column fin radiator 1 and an upper header pipe 2 and a lower header pipe 3 communicating with it, the column fin radiator 1 It includes an aluminum cylinder 11, an aluminum fin 12 is provided on the outer peripheral surface of the aluminum cylinder 11, and a steel pipe 4 closely matched with it is arranged inside the aluminum cylinder 11, and the two sides of the steel pipe 4 The ends are respectively welded with the upper header pipe 2 and the lower header pipe 3. The aluminum cylinder 11 is provided with at least one longitudinal opening 5, and this embodiment is provided with two opposite longitudinal openings 5. The aluminum cylinder 11 A clamping device 6 is provided at the longitudinal opening 5; through the clamping device 6, the aluminum cylinder 11 can be elastically deformed to a certain extent, so as to be tightly hugged on the steel pipe 4. In this way, not only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com