Anti chokage water inflow distributor for manmade marsh

A technology of constructed wetlands and distributors, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of blockage and uneven distribution, prolong the operating life and reduce the construction work. The effect of simple operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

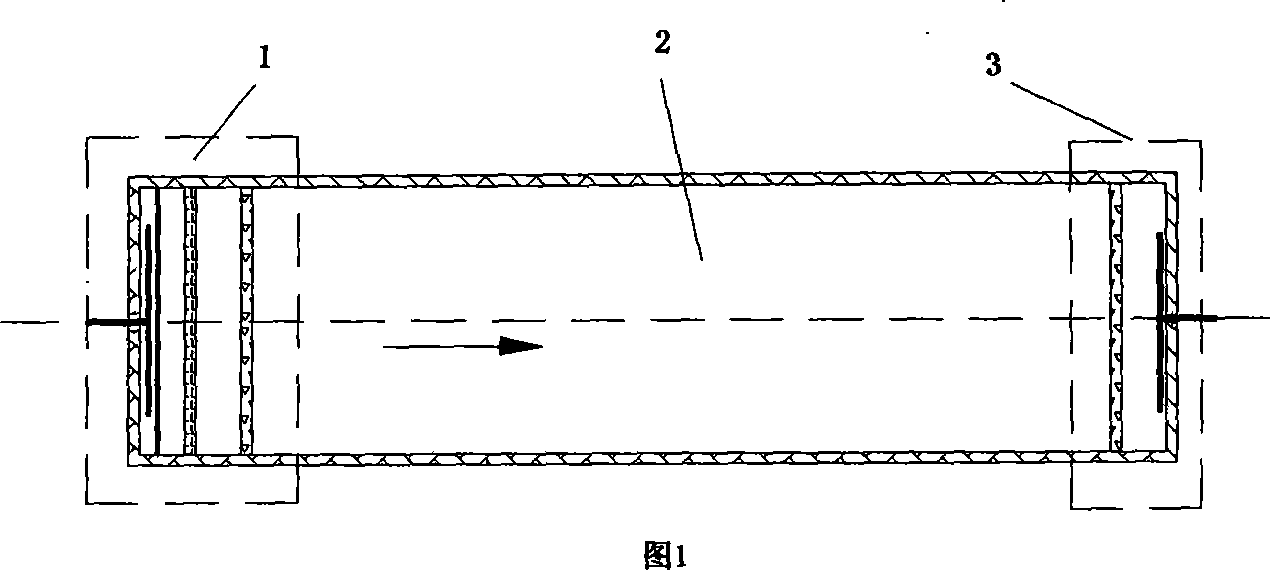

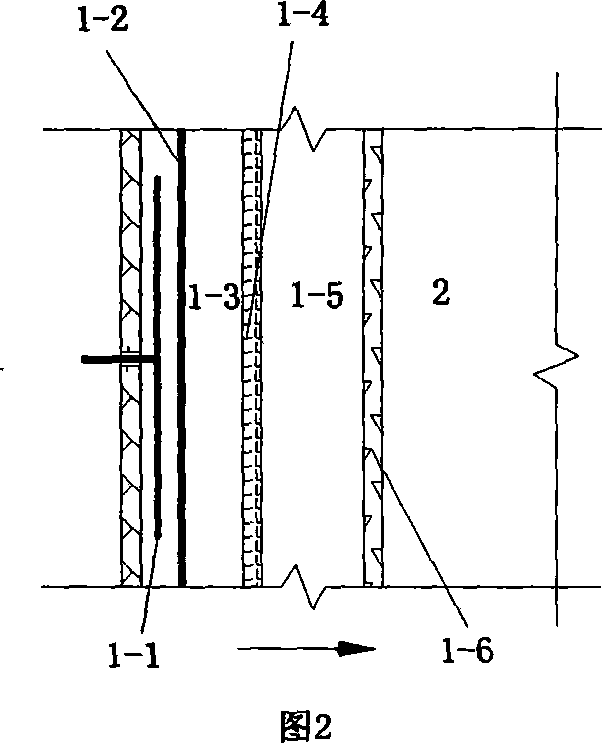

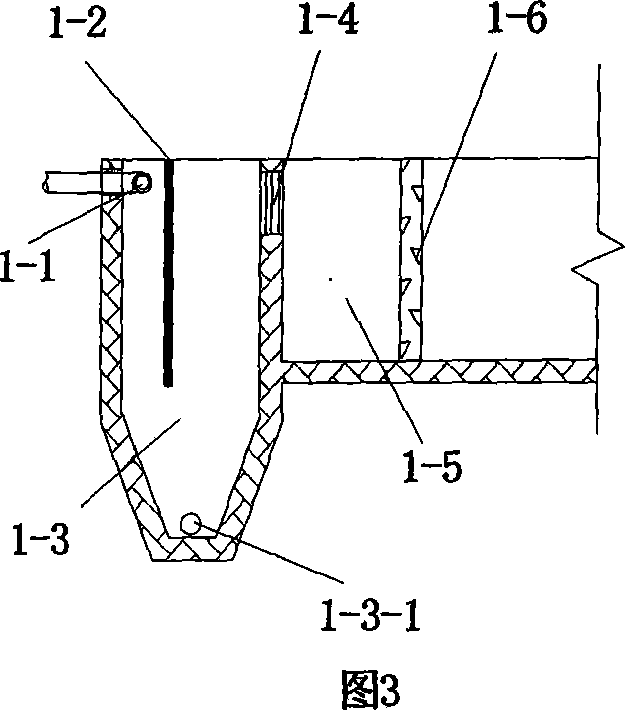

[0025] The invention is an anti-clogging artificial wetland water inlet distributor, which includes six parts: a perforated pipe, an anti-impact baffle, a water collection and sedimentation tank, a grid, a gravel area, and a porous cloth water flower wall.

[0026] Wherein, a perforated pipe 1-1 is provided on the upper part of the water inlet surface of the water collection and sedimentation tank 1-3, and an anti-impact baffle 1-2 is provided in the water collection and sedimentation tank 1-3 facing the entrance of the perforated pipe 1-1. , on the other side of the water collecting and settling tank 1-3, that is, the upper part of the water outlet surface is provided with a grid 1-4 and communicates with the water inlet surface of the gravel area 1-5 next to the water collecting and settling tank 1-3, and the gravel area 1-5 The water outlet surface of 5 is provided with porous cloth water flower wall 1-6, and the outside of porous cloth water flower wall 1-6 is the water out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com