Over-temperature protection method for transformer in reverse exciting topological power and its application circuit

A flyback topology, over-temperature protection technology, applied in emergency protection circuit devices, automatic disconnection emergency protection devices, circuit devices, etc. and other problems, to achieve the effect of no thermal shock, fast protection, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

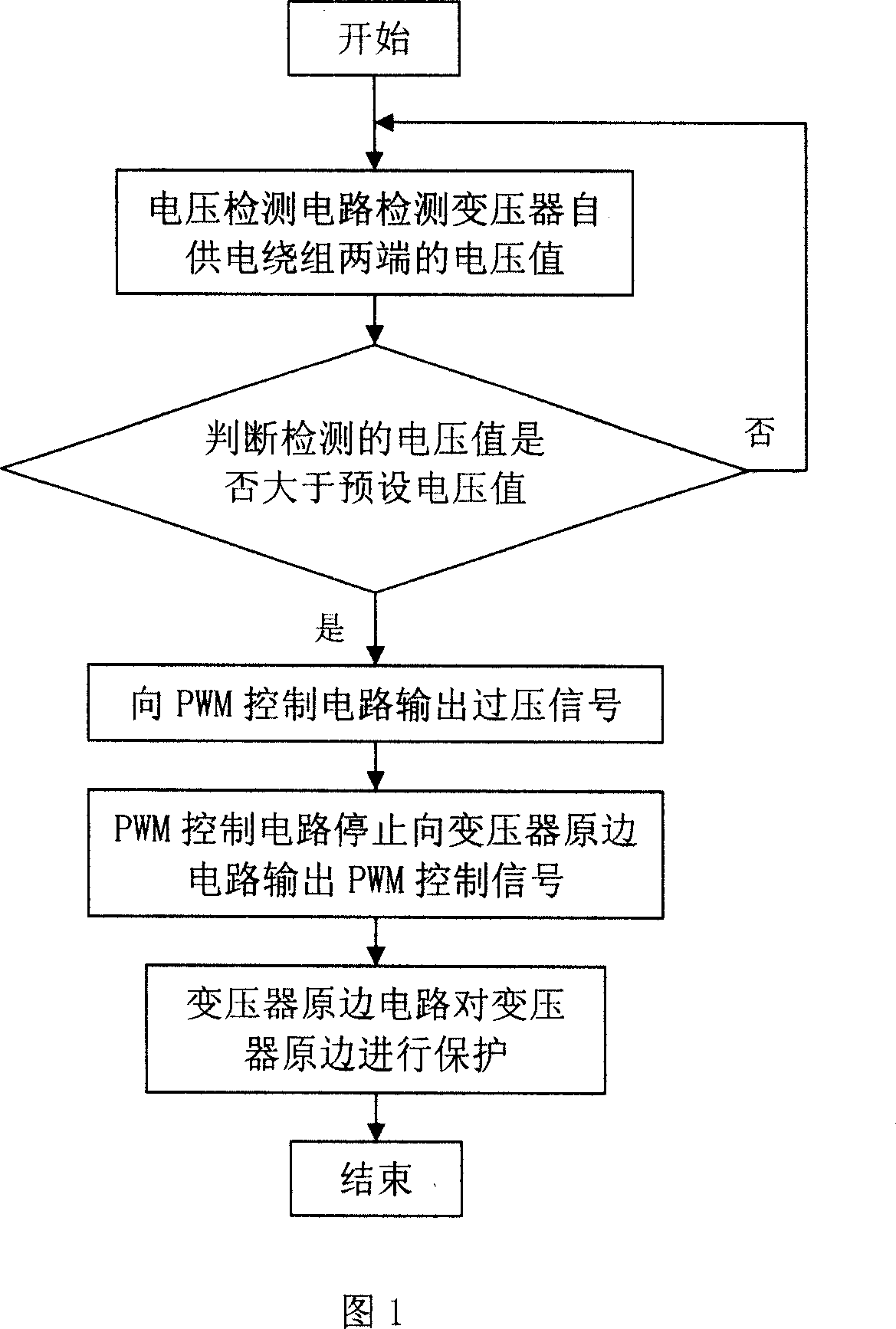

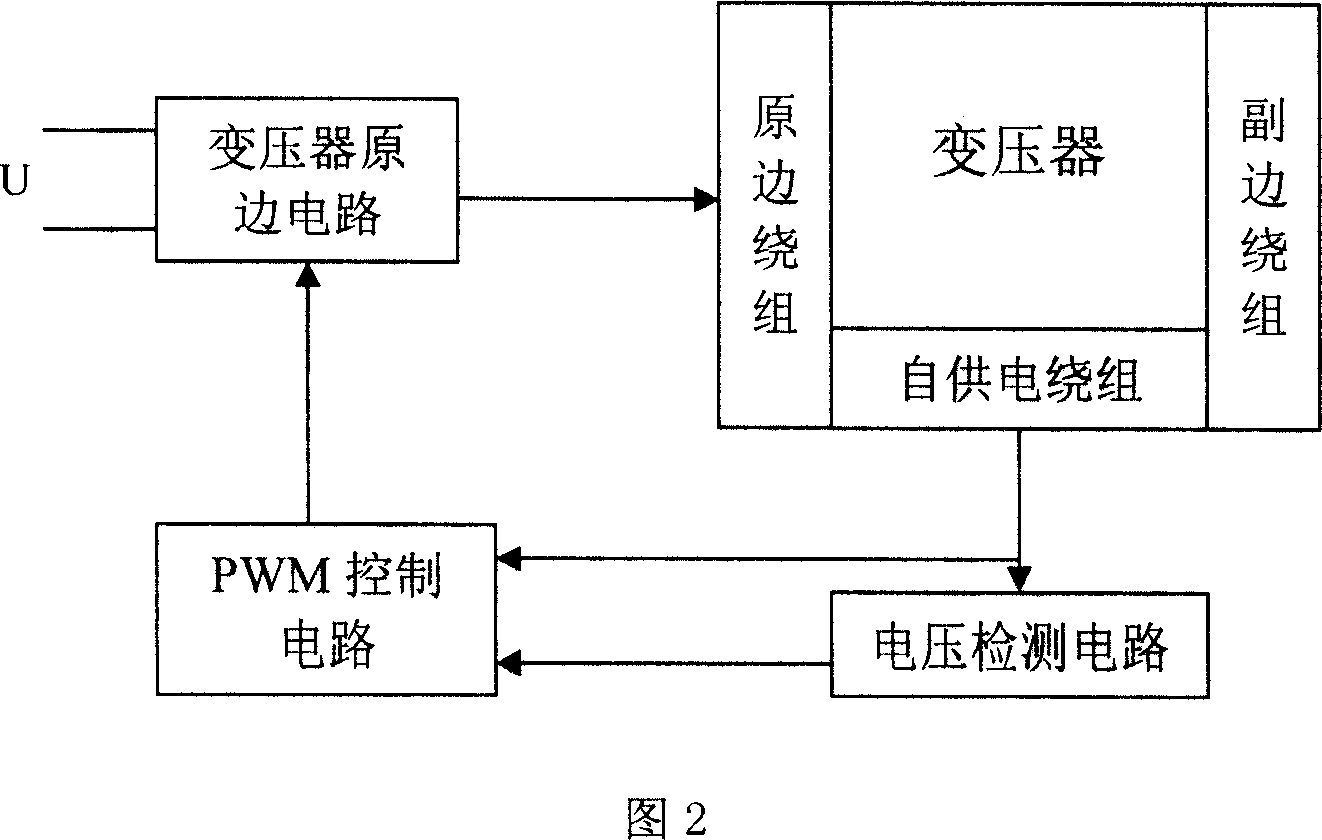

Method used

Image

Examples

Embodiment 1

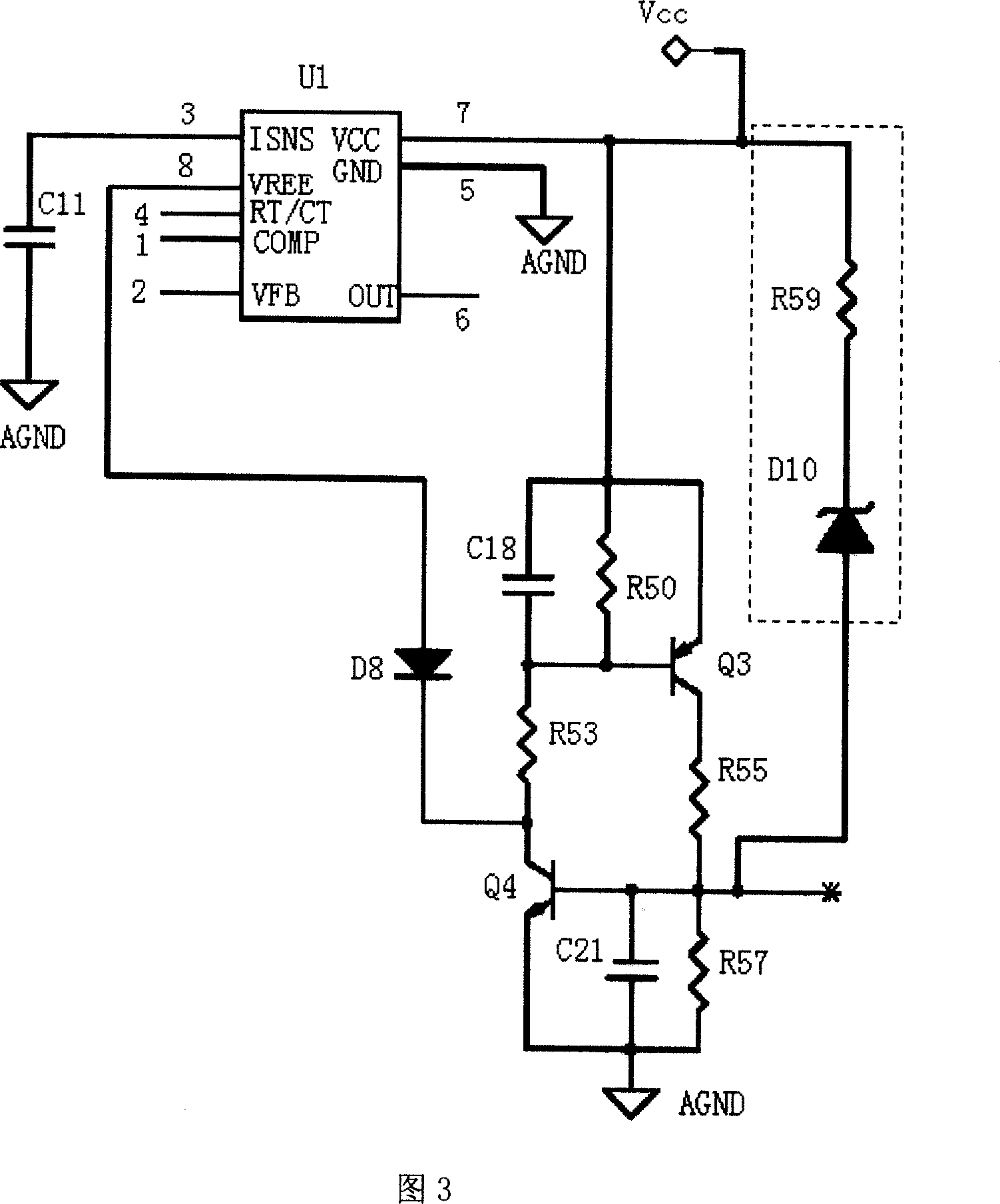

[0037] Fig. 3 is a schematic diagram of a PWM control circuit and a voltage detection circuit in Embodiment 1 of the present invention, wherein,

[0038] The voltage detection circuit includes a resistor R59 and a voltage regulator tube D10. In the frame line in the figure, one end of the resistor R59 is electrically connected to the self-powered winding of the transformer, and this end is used as the input end of the voltage detection circuit. The voltage detection circuit passes the The terminal detects the voltage at both ends of the self-powered winding of the transformer, and the other end of the resistor R59 is connected to the cathode of the voltage regulator D10, and the anode of the voltage regulator D10 is electrically connected to the PWM control circuit, and the anode of the voltage regulator D10 is used as the voltage At the overvoltage signal output end of the detection circuit, the resistor R59 is mainly used to suppress the leakage current of the regulator tube ...

Embodiment 2

[0044] Fig. 4 is a schematic diagram of the voltage detection circuit in this embodiment of the present invention. Compared with Embodiment 1, only the change in the voltage detection circuit is made. The voltage detection circuit mainly includes an operational amplifier U3, a regulator tube D11 and a resistor R54. The cathode of the voltage stabilizing tube D11 is electrically connected to the self-power supply winding of the transformer, and its anode is grounded through the resistor R54, and the anode of the voltage stabilizing tube D11 is connected to the first input terminal of the operational amplifier U3. The second input terminal of the amplifier U3 is connected to the reference power supply, and the output terminal of the operational amplifier U3 is electrically connected to the PWM control circuit; wherein, the first and second input terminals of the operational amplifier U3 are positive and negative input terminals respectively, or The reference power supply includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com