Antivibration supporting apparatus

A supporting device and anti-vibration technology, which is applied to shock absorbers, shock absorber-spring combinations, springs, etc., can solve problems such as difficult to improve ride comfort and insufficient vibration absorption, so as to improve hydraulic pressure and prevent gas Cavitation and improved vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

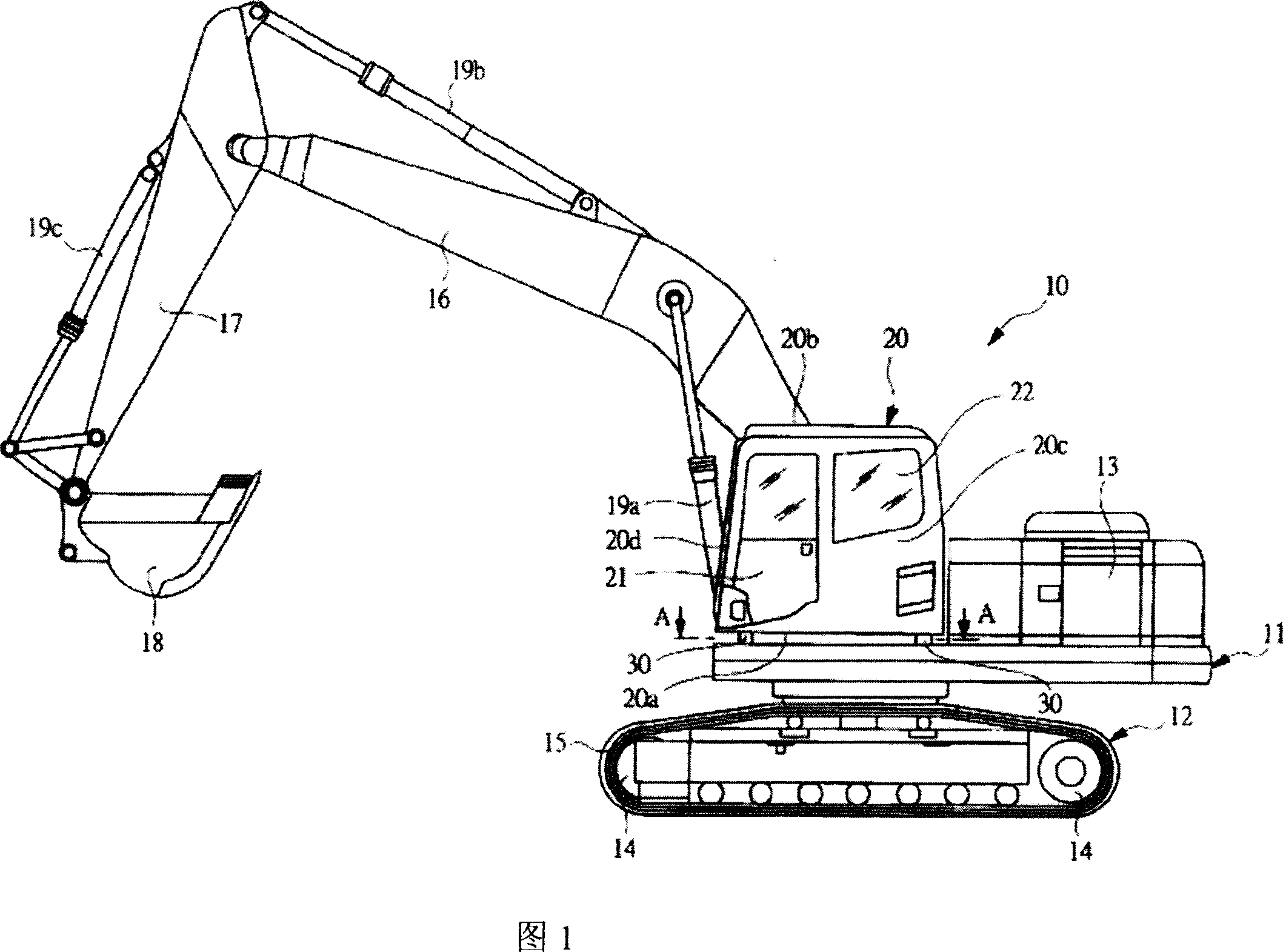

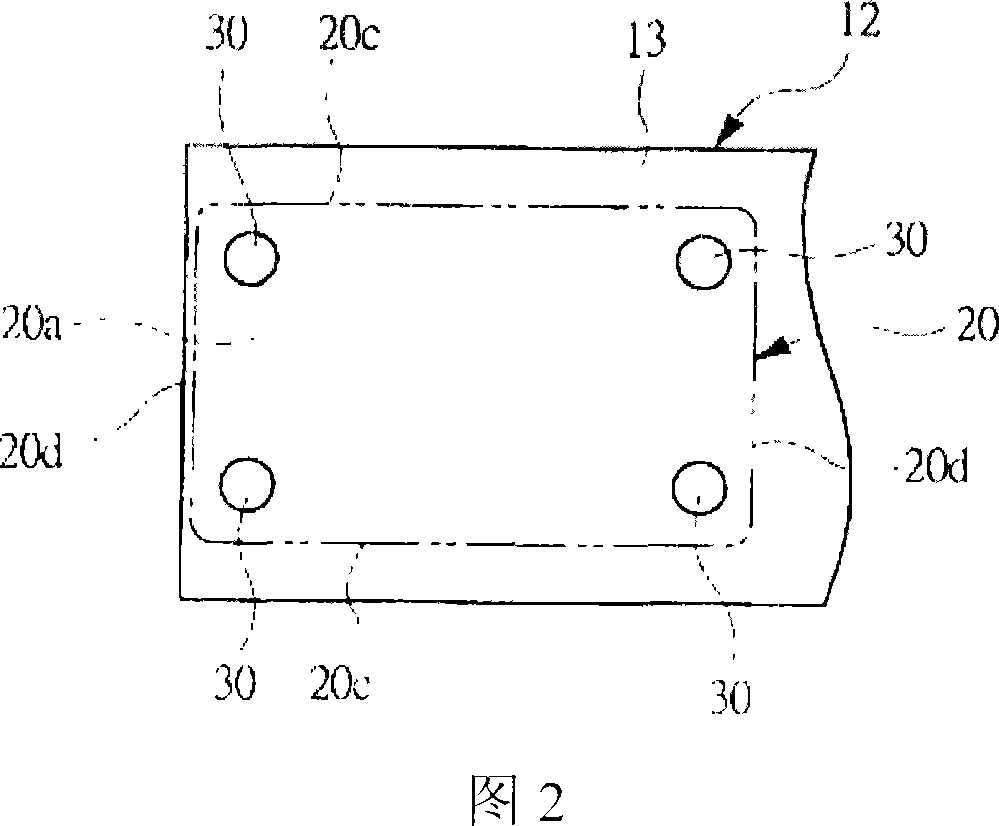

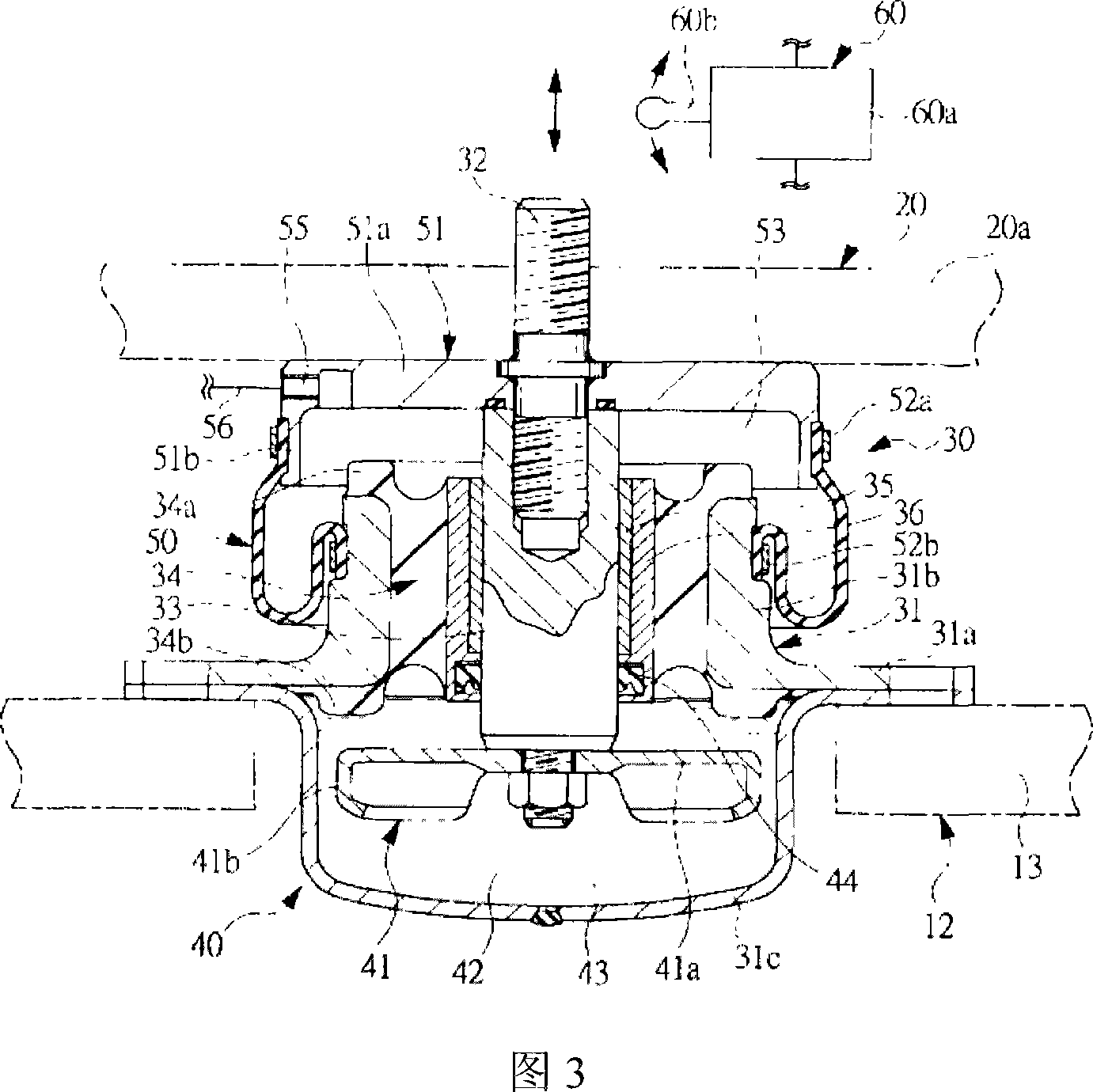

[0054] As shown in FIG. 1 , a vehicle body 11 of a hydraulic shovel 10 , which is a construction machine, has a lower movable body 12 , and a rotary table 13 is rotatably attached to the lower movable body 12 . The lower moving body 12 is a track-type lower moving body having a rail vehicle 15 suspended on sprockets 14 , and may be a crawler-type lower moving body using crawlers or a wheel-type lower moving body using wheels. The boom 16 is mounted on the turntable 13 so that it can swing freely up and down. The arm 17 is mounted on the front end of the boom 16 so that it can swing freely up and down. An oil cylinder 19 a is provided between the turntable 13 and the boom 16 in order to swing the boom 16 up and down. In order to swing the arm 17 in the up and down direction, an oil cylinder 19b is provided between the arm 17 and the boom 16 . In additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com