Gas protective welding machine controlled circuit

A gas protection and control circuit technology, applied in the direction of welding power supply, welding equipment, high frequency current welding equipment, etc. Sparkle, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

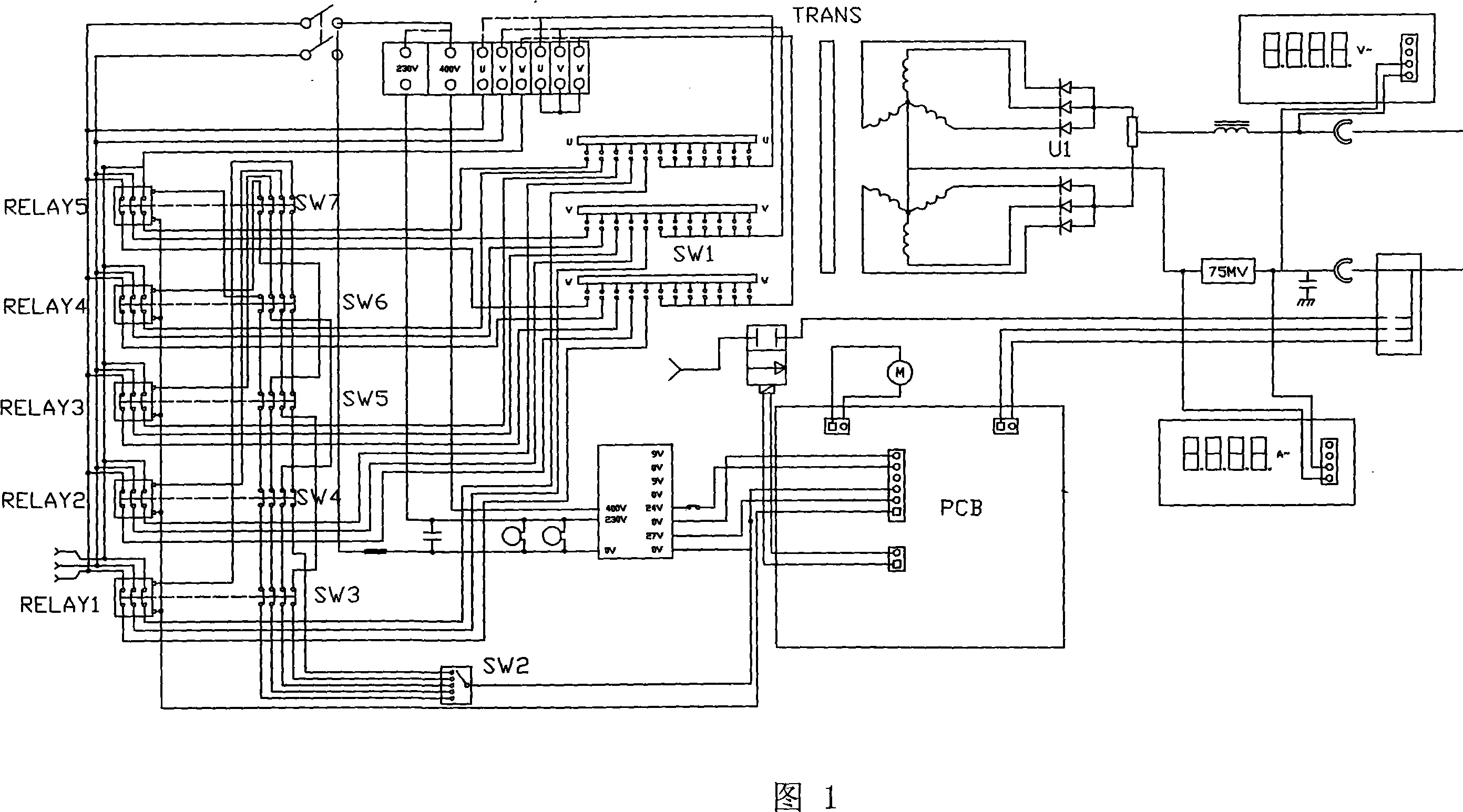

[0009] Referring to Fig. 1, the control circuit of a gas shielded welding machine includes a main control circuit board PCB, a gear switch SW1, a transformer TRANS and a rectifier circuit U1, the primary coil of the transformer TRANS has multiple taps, and the gear switch SW1 The contacts are respectively connected to the taps, and the secondary of the transformer TRANS is connected to the rectifier circuit U1 and then connected to the welding torch. It is characterized in that it is also equipped with a wire-controlled gear selection switch SW2 and relays RELAY1 to RELAY5, and a selection terminal of the wire-controlled gear selection switch SW2 It is connected to the output end of the main control circuit board PCB, and the output end of the wire-controlled gear selection switch SW2 is respectively connected to the coil input ends of the corresponding relays RELAY1 to RELAY5, and the power input is connected to the gear switch SW1 after the switches of the relays RELAY1 to REL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com