Rotor, drive converting apparatus, cleaning apparatus, wiping apparatus, and liquid ejection apparatus

A technology of drive conversion and rotor, applied in the direction of transmission, printing device, printing, etc., can solve the problems such as difficult wiper wiping and cleaning recording head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

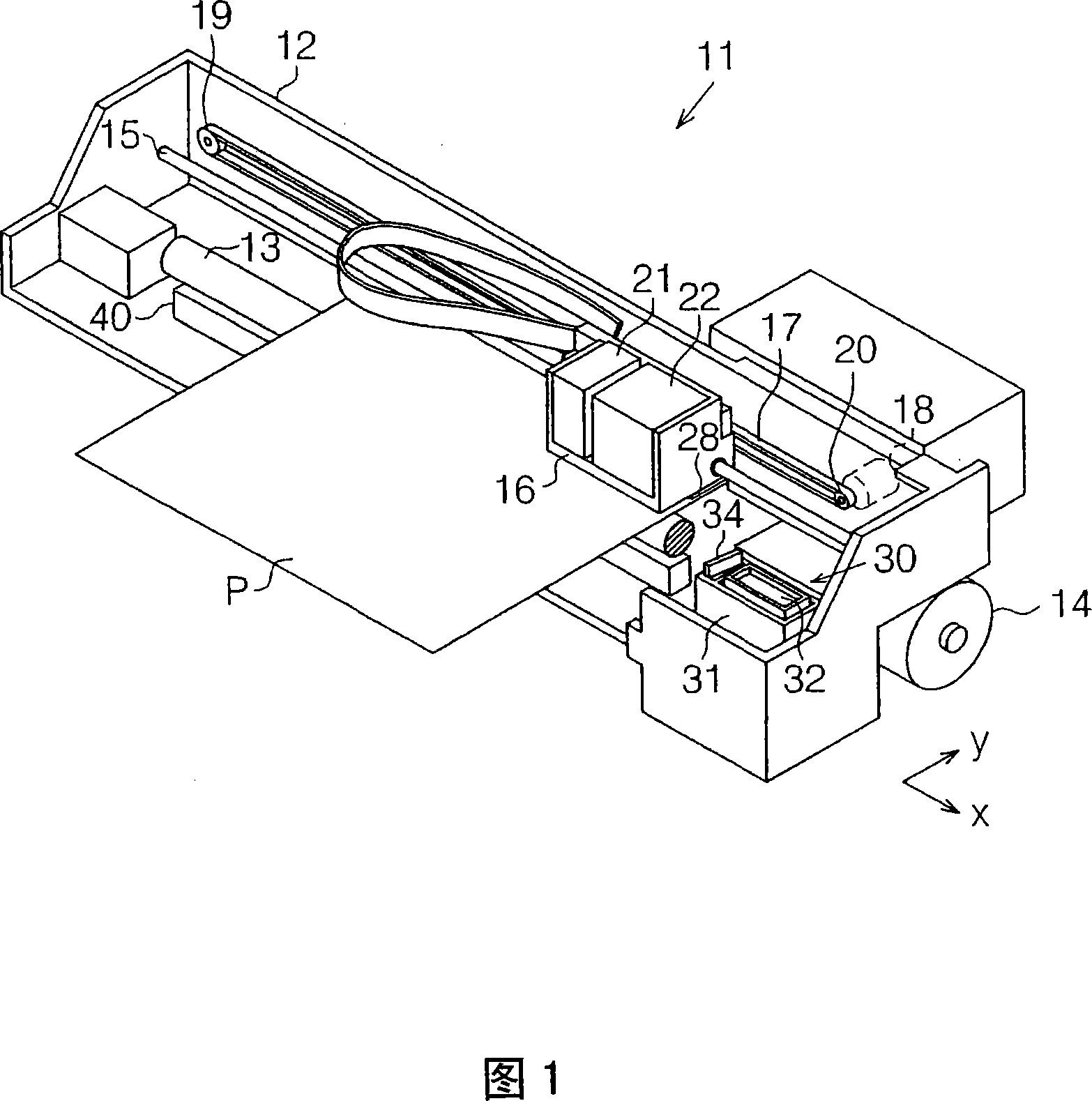

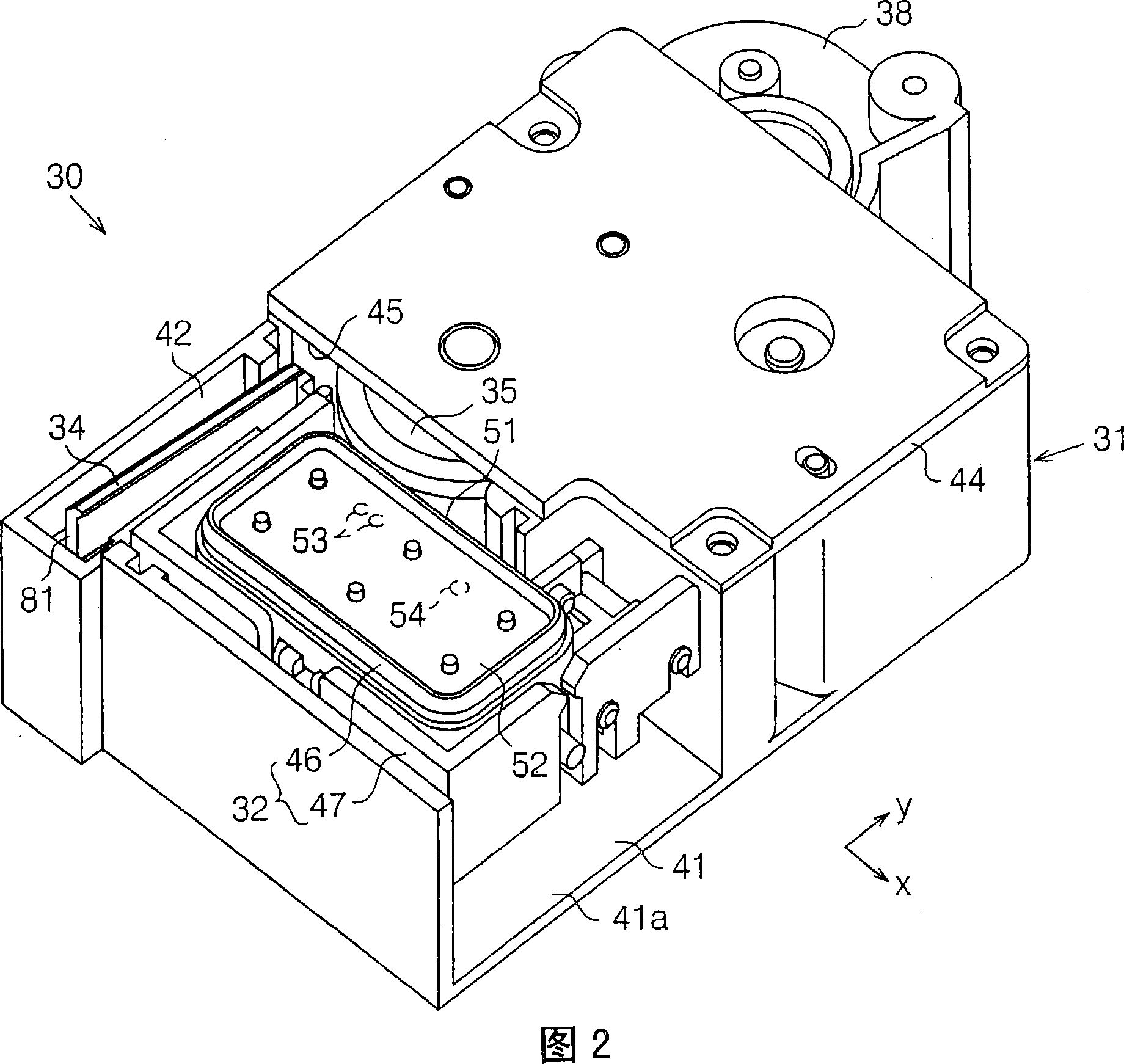

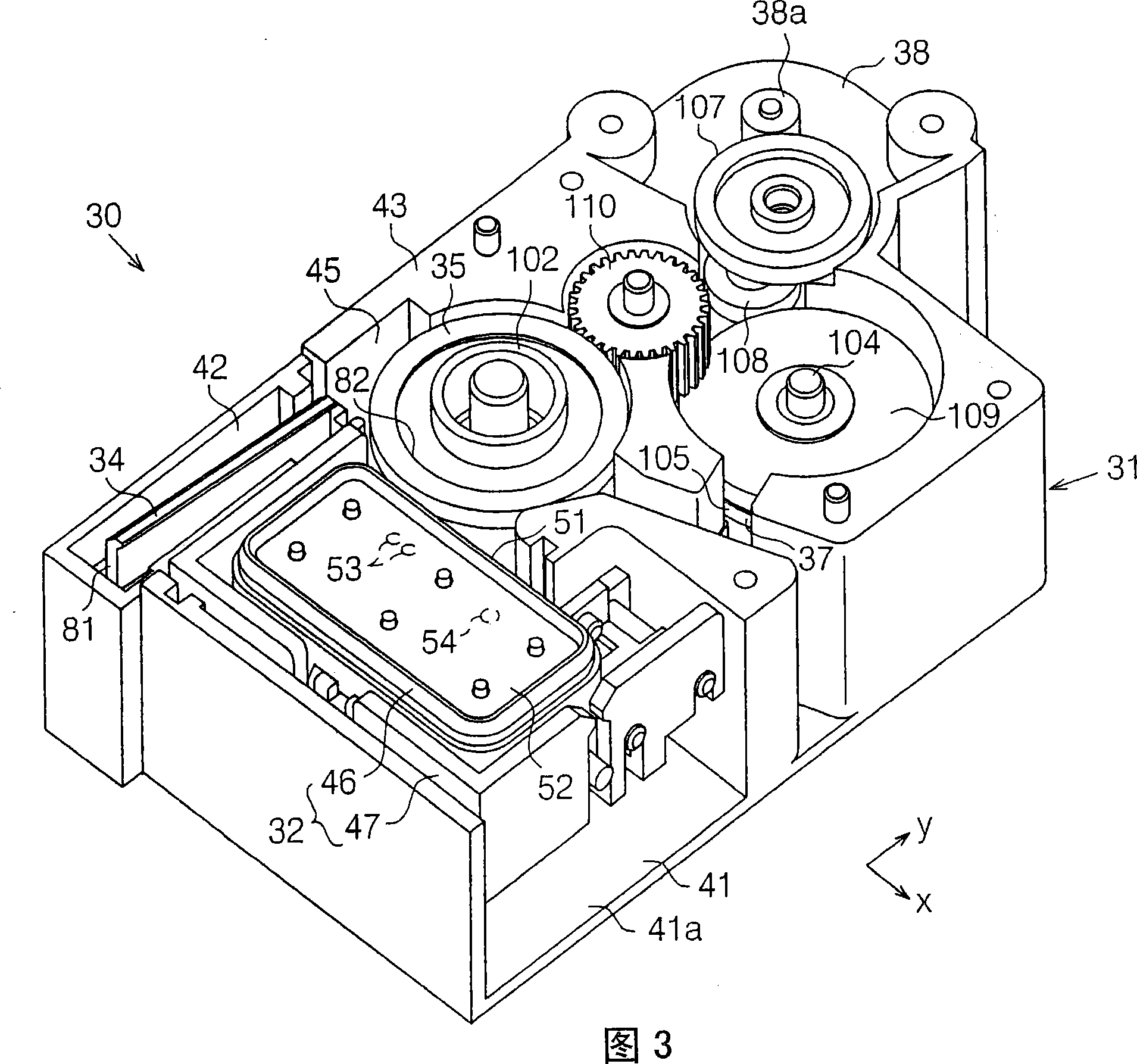

[0069] A first embodiment of the present invention will be described below with reference to FIGS. 1-6.

[0070] As shown in FIG. 1 , an ink jet type recording device 11 as a liquid jet device has a frame 12 , a platen 13 suspended across the frame 12 , and an unillustrated paper feed mechanism equipped with a feed motor 14 . The platen 13 is a supporting mechanism for supporting the paper P, and the fed paper P driven by the feeding motor 14 is guided toward the top surface. The feed motor 14 drives unshown rollers to feed the paper P supported on the platen 13 in the direction of the arrow Y shown in FIG. 1 . A waste liquid tank 40 holding used ink is provided under the platen 13 .

[0071] A drive pulley 19 and a driven pulley 20 are fixed to the frame 12 . A reversible carriage motor 18 is coupled to a drive pulley 19 . A timing belt 17 extends around a pair of pulleys 19 and 20 . The bracket 16 is fixed to a timing belt 17 . In addition, a guide 15 extending parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com