Single-one valve for tail gas purification of general small-size gasoline engine

A small gasoline engine and exhaust gas purification technology, applied in exhaust devices, mechanical equipment, engine components, etc., can solve the problems of troublesome installation, weak versatility, poor stability, etc., to reduce production costs, and achieve high versatility. Low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

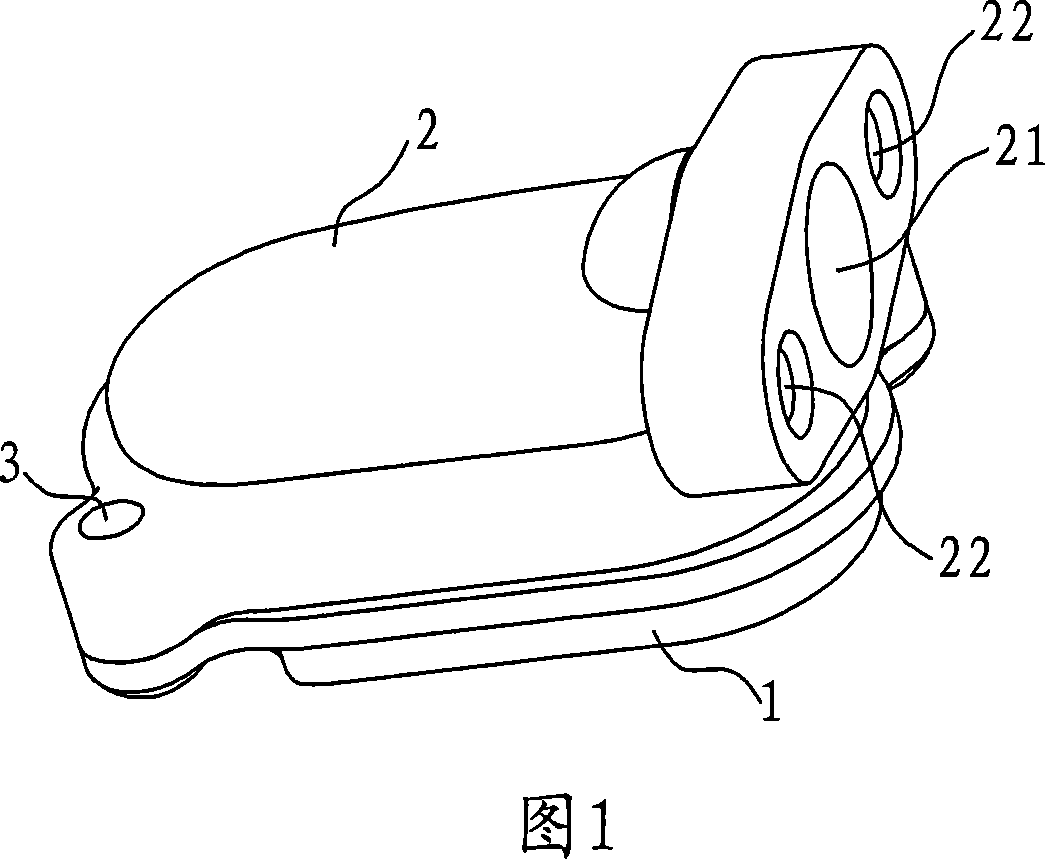

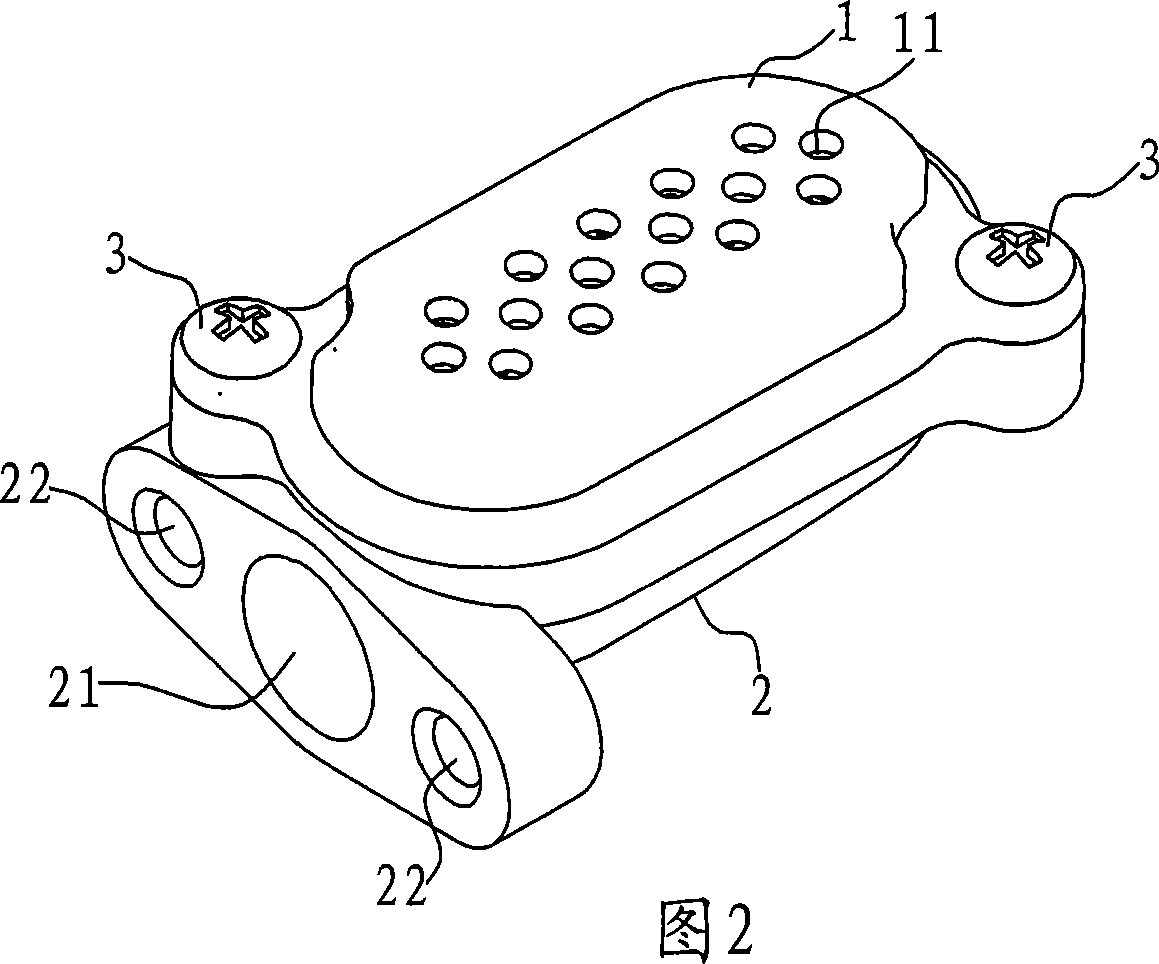

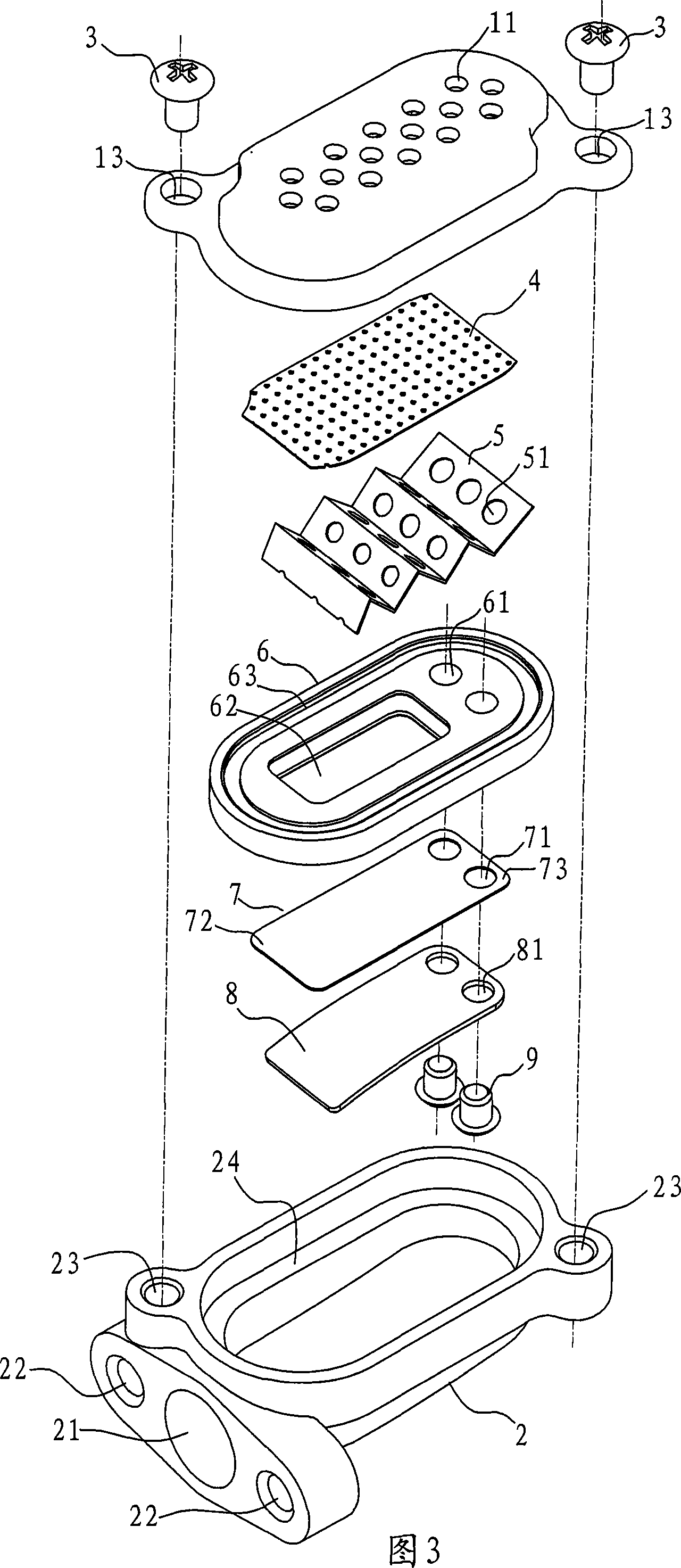

[0026] Embodiment, with reference to Fig. 1 and Fig. 2, the general-purpose small-sized gasoline engine exhaust gas purification check valve in the present embodiment comprises housing, reed 7, body 6, muffler plate 5, filter screen 4 and baffle plate 8, housing It includes an upper case 1 and a lower case 2 .

[0027] Referring to Fig. 3 and Fig. 4, the upper shell 1 and the lower shell 2 are connected by two bolts 3 to the upper screw hole 13 and the lower screw hole 23 to realize the connection and fixation. The upper shell 1 is provided with a plurality of air inlet holes 11, The lower housing 2 is provided with an air outlet 21 , and the lower housing 2 is provided with a slot 24 around the inner wall, and two sides of the lower housing air outlet 21 are provided with screw holes 22 suitable for installation. The opening directions of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com