Secondary utilization process and device for water power residual energy

A process and residual energy technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as water waste, achieve the effect of increasing power generation and avoiding harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

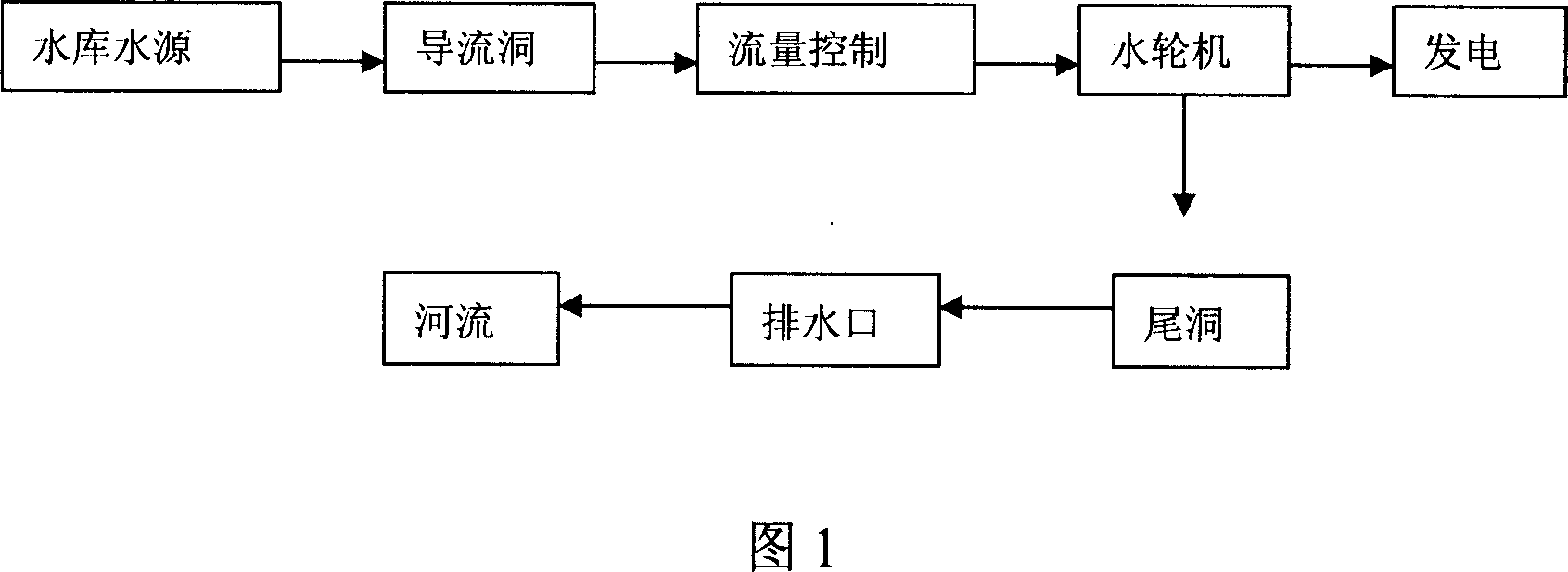

[0014] Figure 1 is a flow chart of the existing water energy utilization process. The water source enters the water turbine to generate electricity through the flow control of the diversion tunnel, then enters the tail hole, and then discharges into the river through the tail hole outlet.

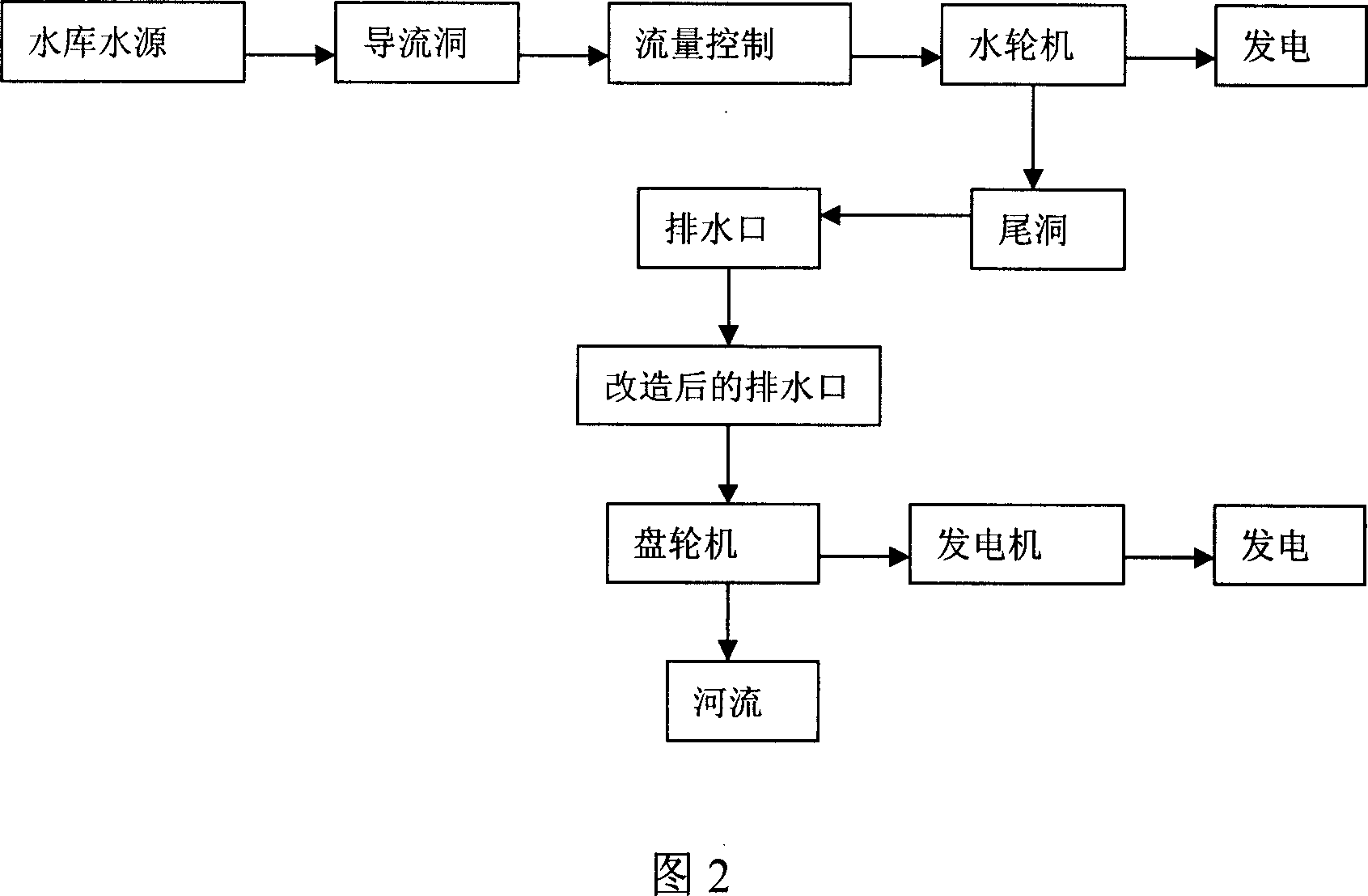

[0015] Fig. 2 is the process flow chart of the secondary utilization of water energy in the present invention. The water source of the reservoir enters the tail hole to the drain outlet after the water source is generated once through the water turbine through the diversion hole, and then the size of the tail hole outlet is determined according to the flow rate, and the water passes through the tail hole outlet. , punching the disk turbine to make the disk turbine rotate, the disk turbine drives the generator to generate electricity, and the water flowing through the disk turbine enters the river.

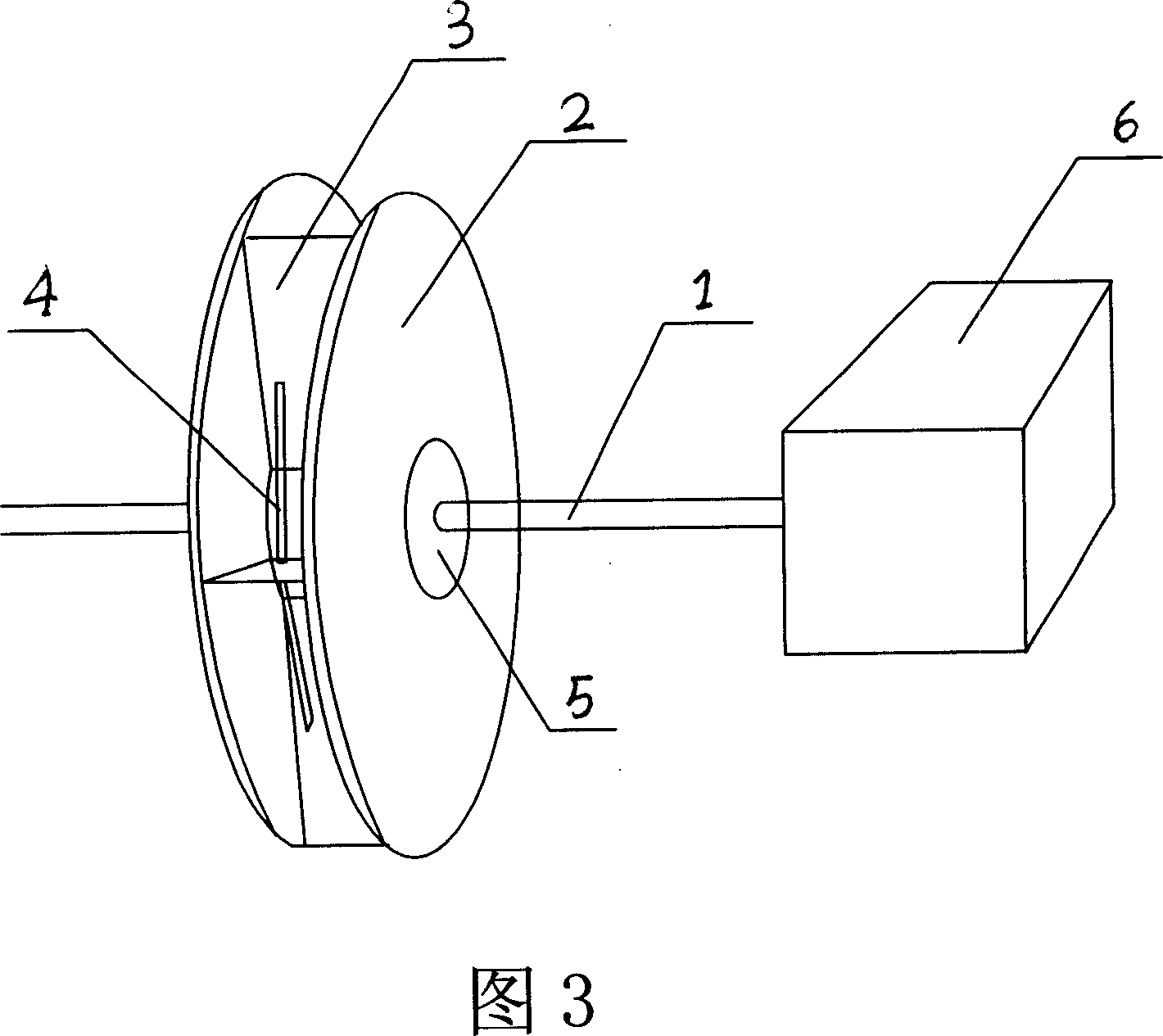

[0016] Fig. 3 is a schematic diagram of the structure of the disc wheel machine. The disc whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com