Liquid crystal display panel support

A liquid crystal display panel, carrier technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as different optical properties, different brightness and darkness, and product stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

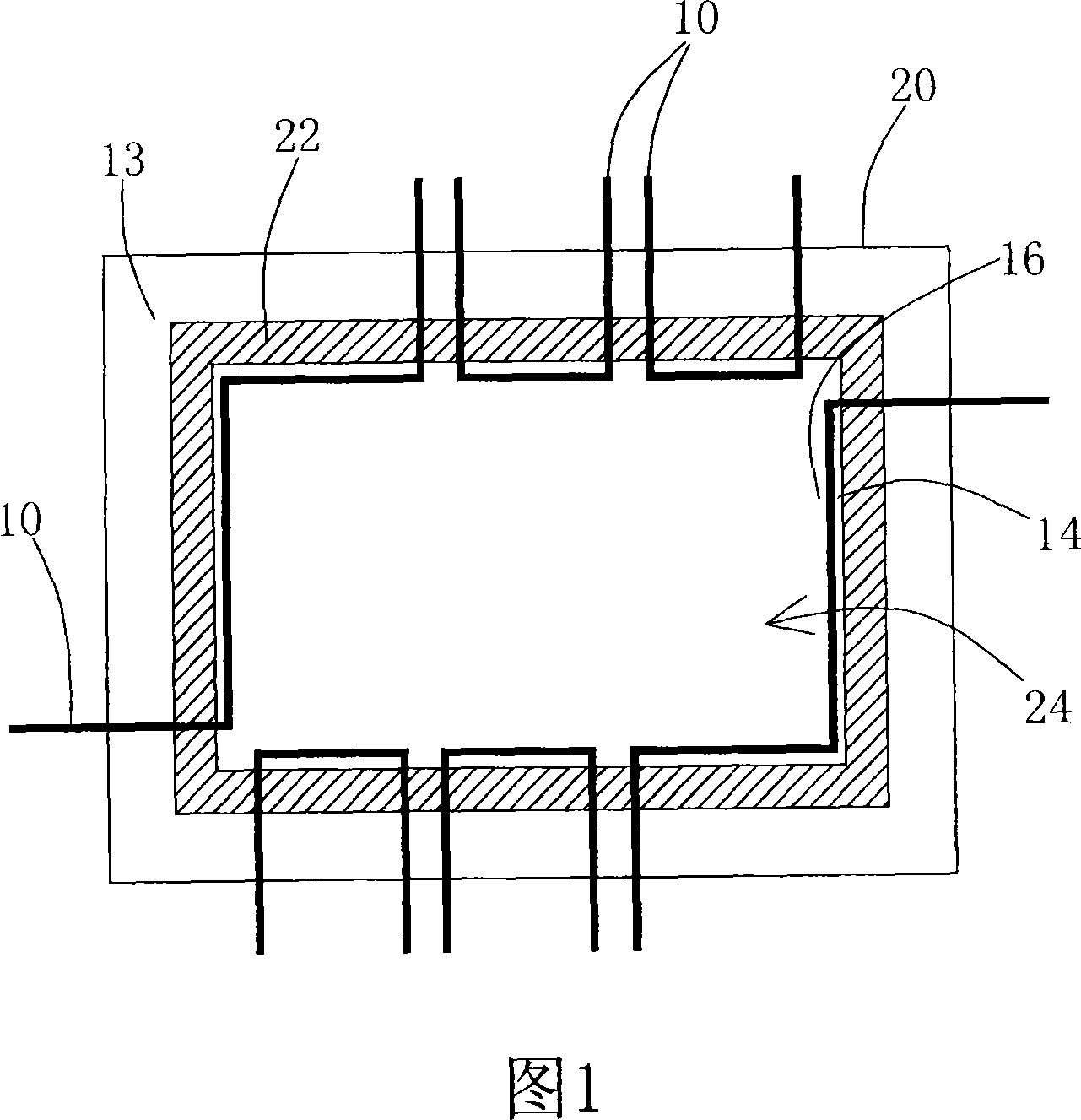

[0056] The present invention relates to a method for making a liquid crystal display panel with both support and voltage application and a supporting carrier used in conjunction with it. In a preferred embodiment, the present invention is mainly applied to the Polymer Stabilized Alignment (PSA) process, combined with ultraviolet (UV) cross-linking exposure, so that the liquid crystal molecules in the liquid crystal display panel generate a specific pre-tilt angle, and then achieve control The process of aligning liquid crystal molecules. In addition, in a preferred process, in order to judge whether the alignment of liquid crystal molecules is good, automatic optical inspection (AOI) can be used to detect before / after exposure and cross-linking. The specific embodiments and steps of the present invention will be further described below with reference to the accompanying drawings.

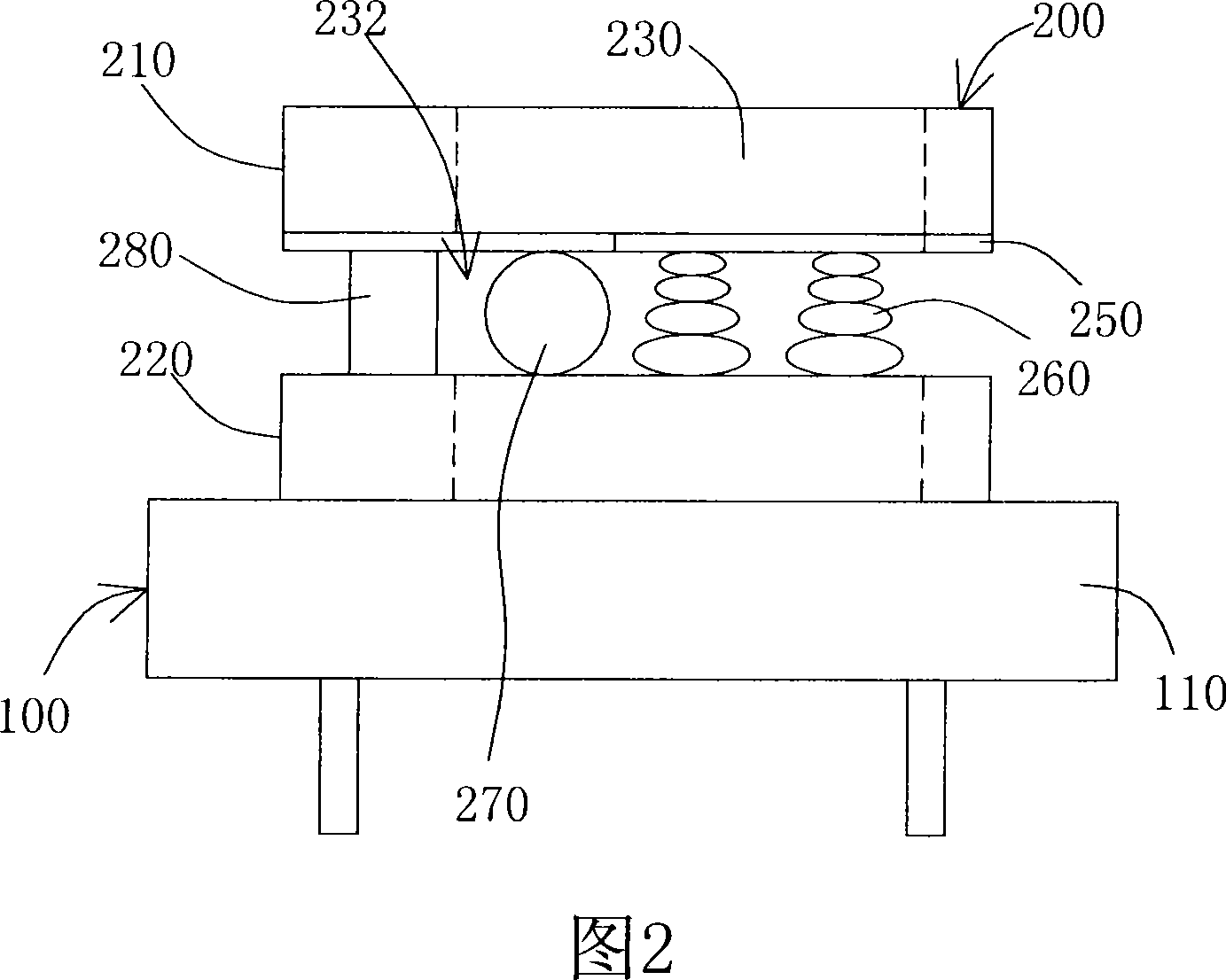

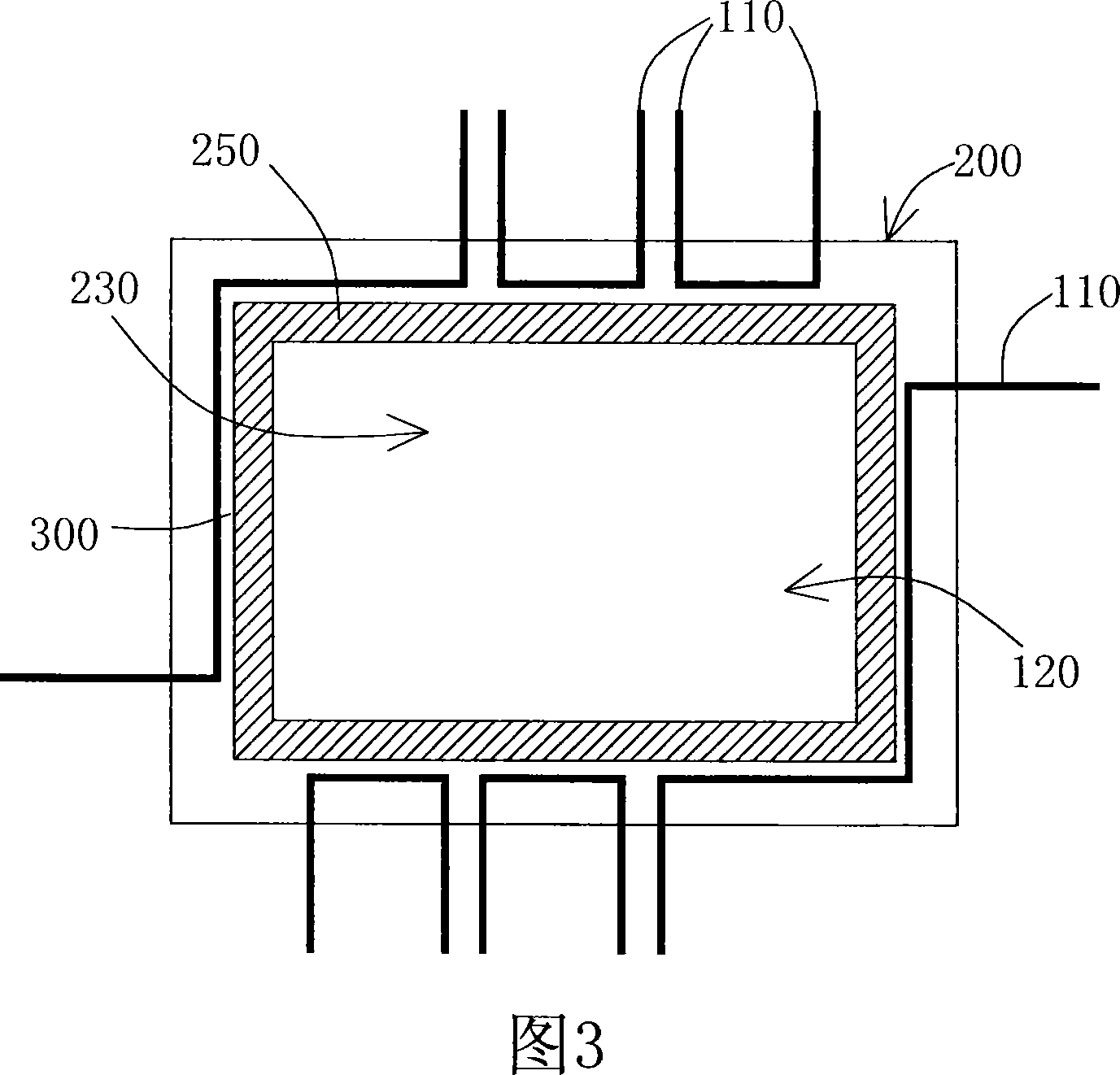

[0057] FIG. 2 and FIG. 3 are respectively a cross-sectional view and a top view of a liquid cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com