Method for production of a substrate coated with a zeolite layer

A substrate and zeolite technology, applied in coatings, chemical instruments and methods, metal material coating technology, etc., can solve problems such as perfection, unsatisfactory methods, poor fixation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

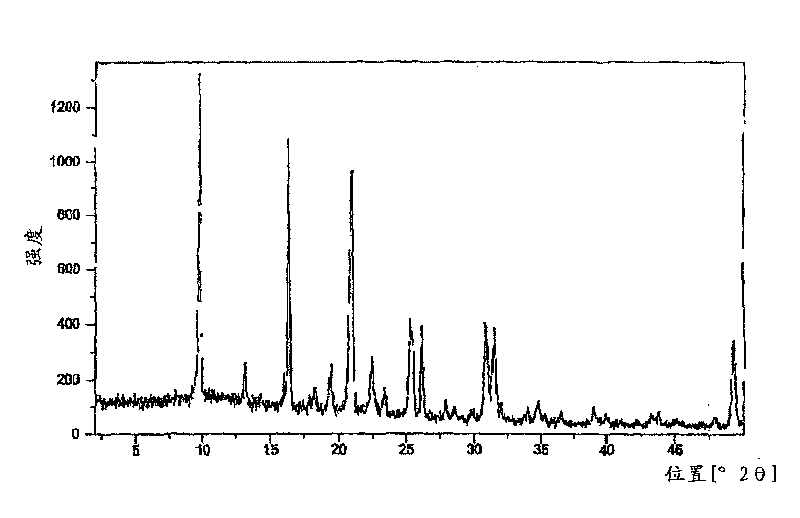

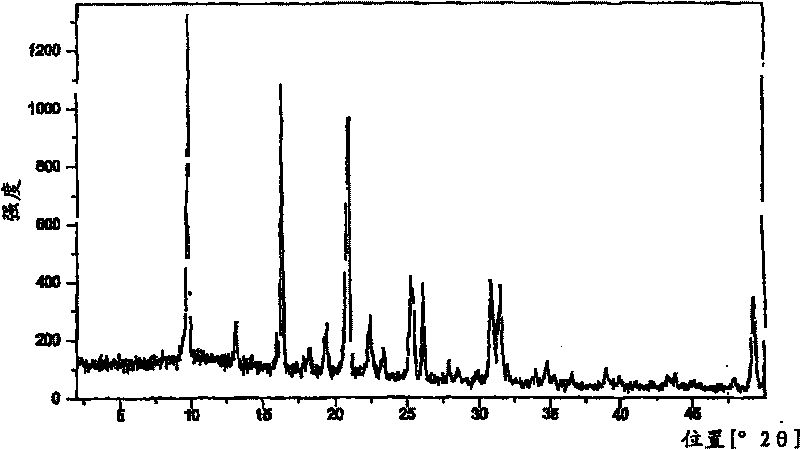

Image

Examples

Embodiment Construction

[0029] The method according to the invention will be illustrated below by means of an example in which SAPO 34 is produced on an aluminum substrate.

[0030] First, 23.6 grams of water, and 2.38 grams of 85% phosphoric acid as a phosphorus source material, and 2.0 grams of silica sol (30.4% SiO in water as a silicon source material) were prepared. 2 ) and 5.4 g of morpholine as a template molecule in an aqueous suspension. The above weight figures are rounded off here. Specifically, here phosphoric acid and 9.4 grams of water were previously placed in a mixing vessel to prepare a first partial mixture. Separately, a second partial mixture consisting of 2.0 g of silica sol and 5.4 g of morpholine and 9.4 g of water was prepared and added dropwise to the first partial mixture with continuous stirring. The first partial mixture finally provided consisted of 6 grams of water, 6 grams of 85% phosphoric acid and 3.6 grams of pseudoboehmite. In addition, a second partial mixture c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com