Control valve type lead battery

A lead-acid battery, valve-controlled technology, applied in secondary batteries, battery pack parts, battery caps/end caps, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

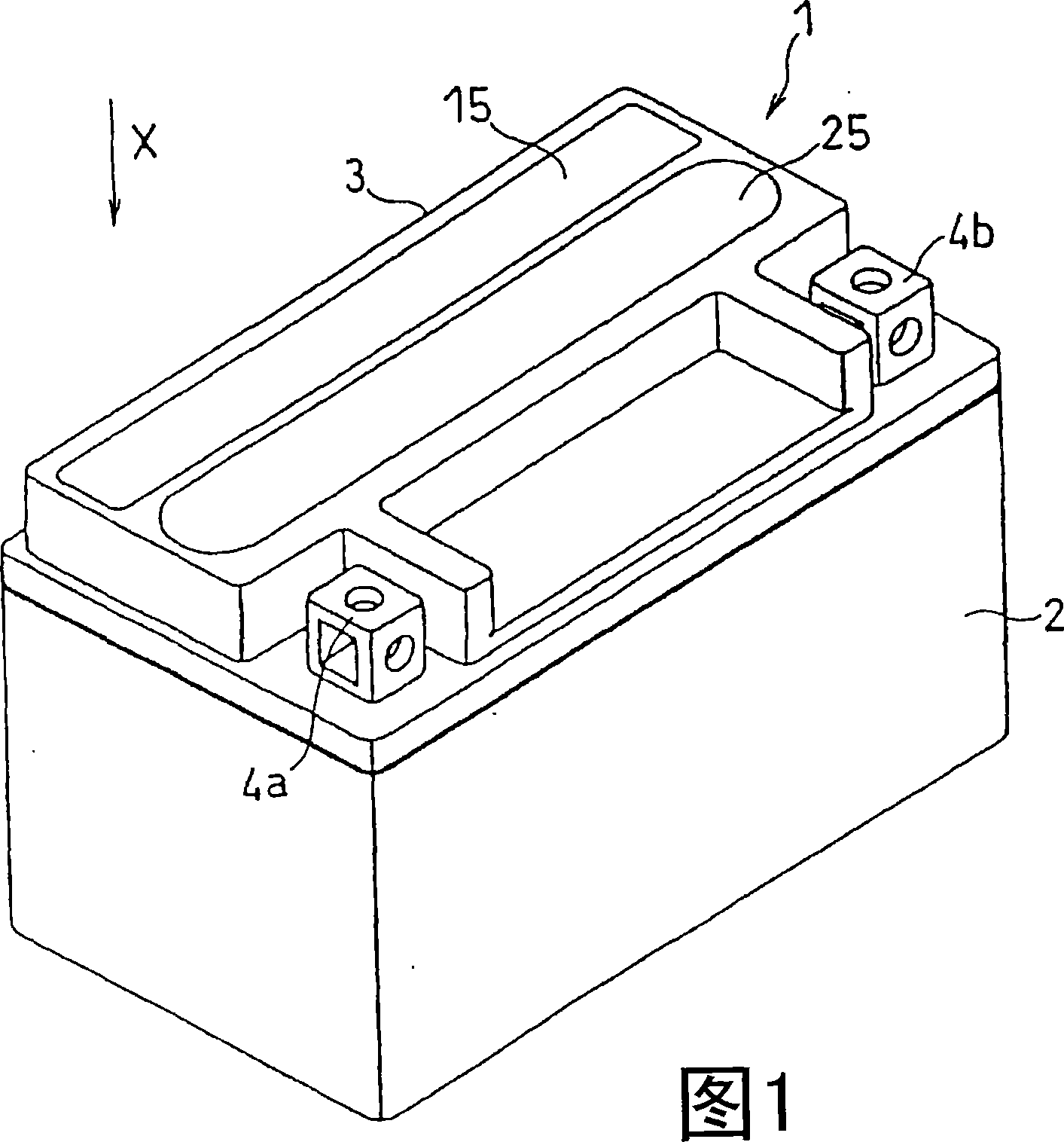

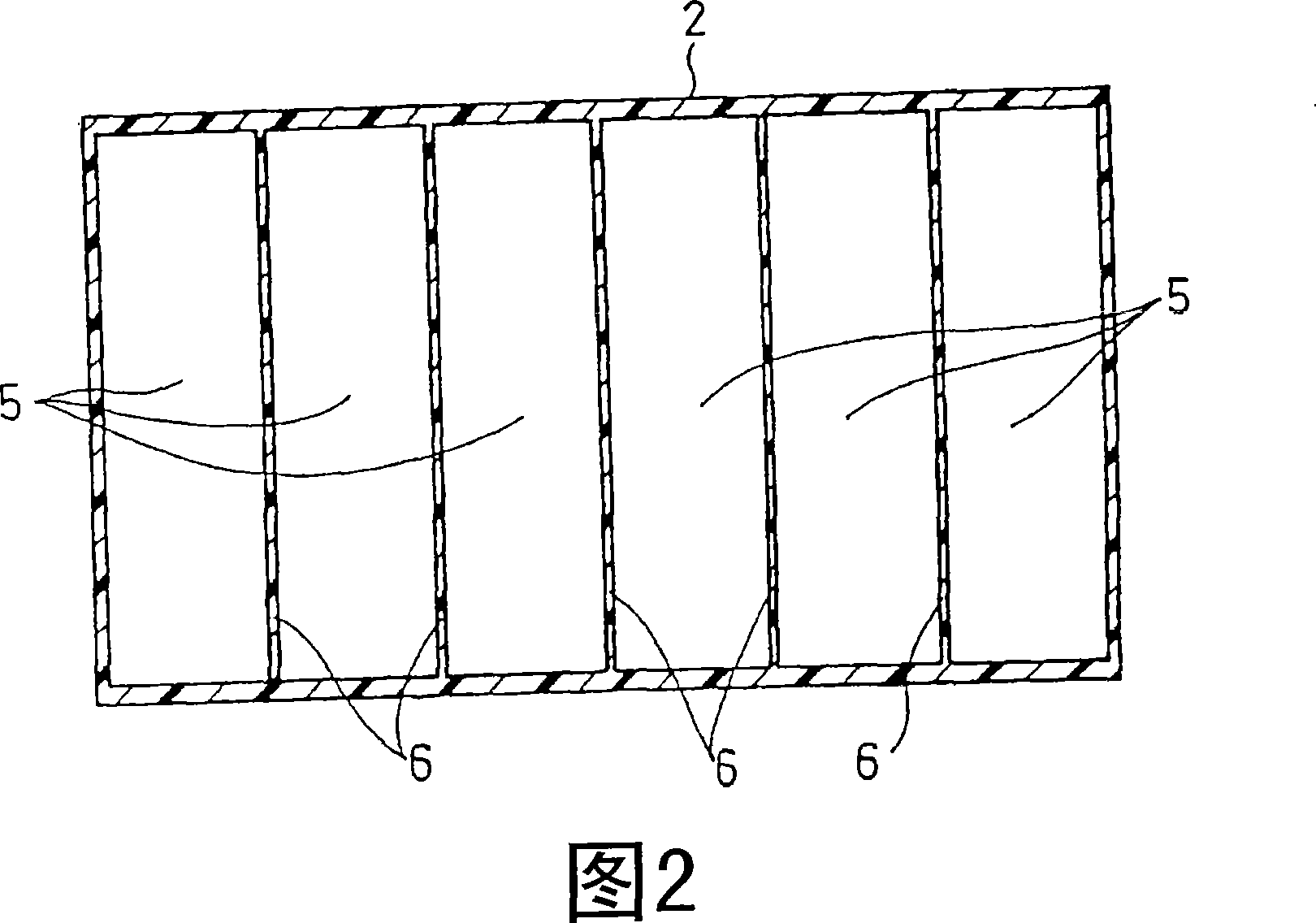

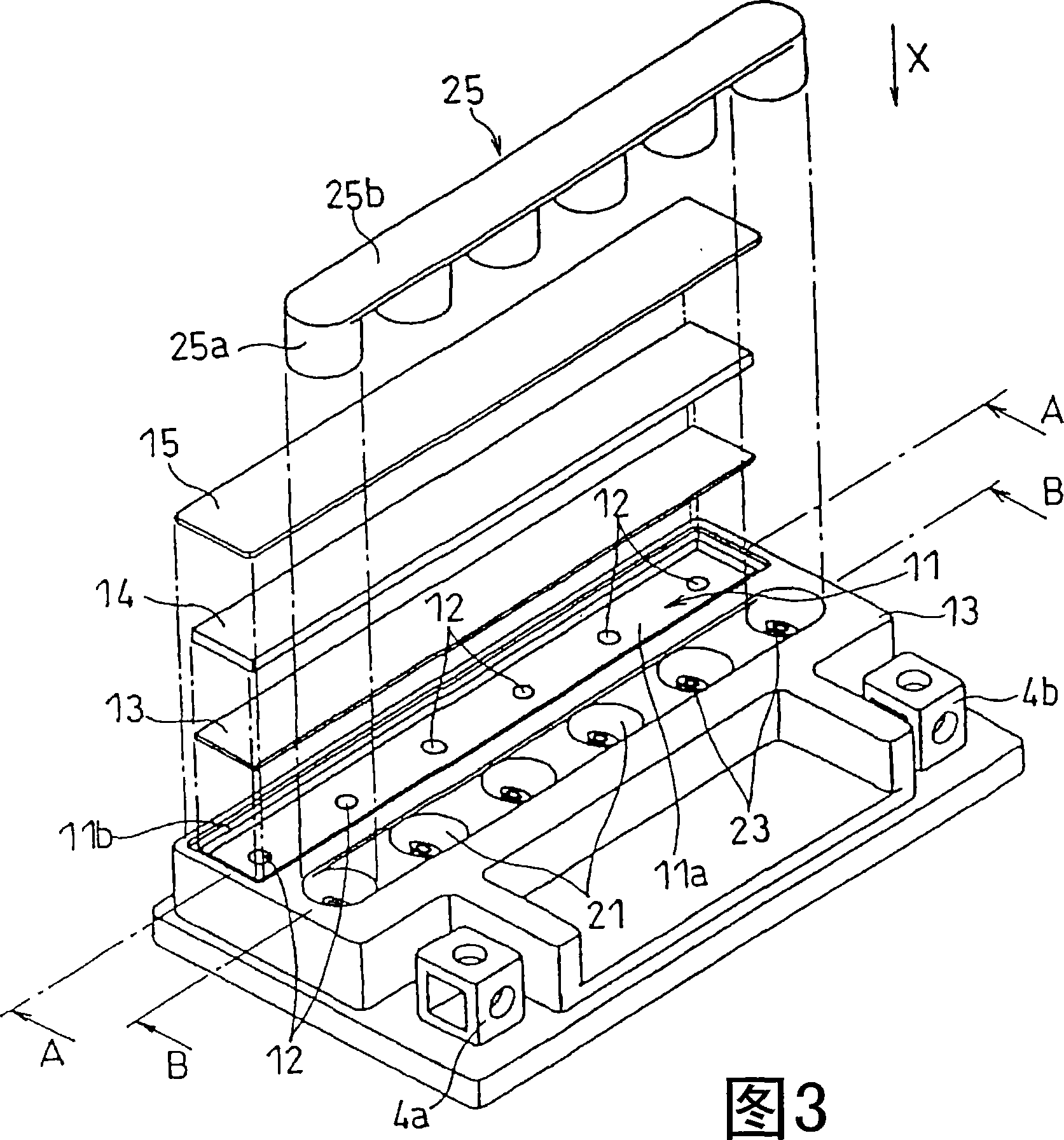

[0105] In this example, a lead-acid storage battery A (12V-6Ah) of the present invention using the battery cover 3 having the structure shown in FIGS. 1-6 of the above-described embodiment was manufactured.

[0106] The plate-shaped valve body 13 serving as a safety valve was manufactured using neoprene (having a thickness of 0.3 mm and an international rubber hardness of 60 degrees). Sheet 14 was fabricated from EPDM foam (thickness 2.0 mm) with a void ratio of 90%. Furthermore, after fixing the top plate 15 to the battery cover 3 in battery manufacture, the thickness of the sheet 14 was set at 1.4 mm when compressed. Therefore, the sum of the thickness of the valve body 13 and the thickness of the sheet 14 at the time of manufacturing the battery was 1.7 mm. In addition, silicone oil is applied to the surface of the valve body 13 that is in contact with the bottom 11 a of the exhaust chamber 11 .

[0107] In the manufacture of the electrode plate group, each positive elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com