Dumping car bottom board gas control heating method

A heating method and dump truck technology, applied in heating/cooling equipment, vehicle parts, air handling equipment, etc., can solve problems such as air leakage, affecting the effect of floor heating, and poor control reliability of the control mechanism, so as to improve the effect and control Convenience and reliability, the effect of eliminating air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

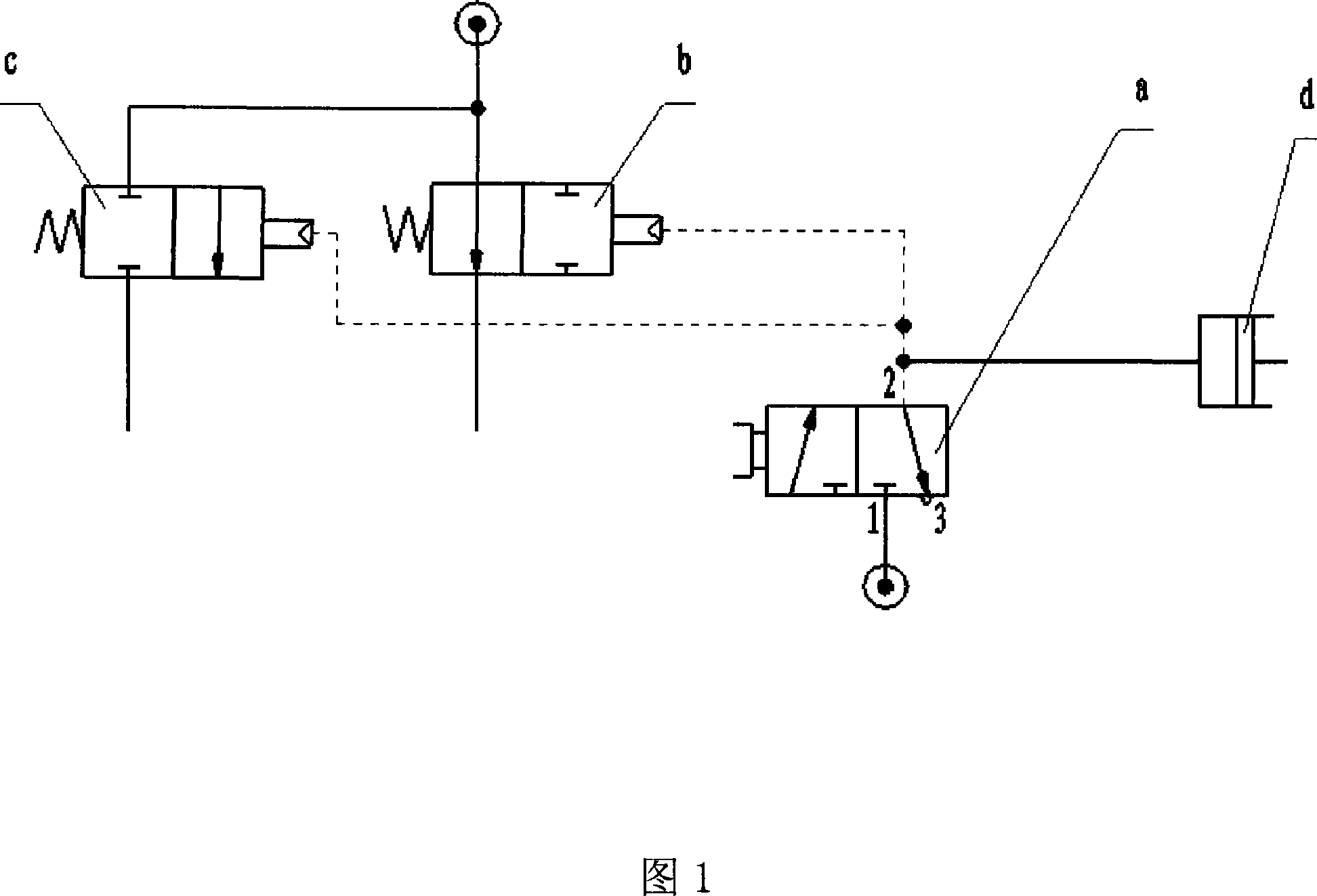

[0008] Referring to attached drawing 1, the power take-off switch a is actually a two-position three-way valve, which is normally closed when driving, that is, port 1 and port 2 of the three-way valve are disconnected. At this time, the power take-off cylinder d has no input Gas, does not work, that is, the lifting system of the dump truck does not work; when parking for lifting operations, the power take-off switch is connected, that is, port 1 and port 2 are connected, the power take-off is connected to the pump, and the lifting system works .

[0009] It can be seen from Figure 1 that the butterfly valve c on the exhaust pipe and the butterfly valve b on the branch of the exhaust pipe share an air port 2 with the power take-off. When driving, port 2 and port 3 (exhaust port of the power take-off) are connected, there is no air pressure in the air circuit, the power take-off and the pump are not connected, the lifting system is not working, and the butterfly valve c on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com