Non-metal expansion joint for solving problem of non-uniform expansion of large-caliber flue

A non-metallic expansion joint technology, applied in the field of thermoelectric facilities, can solve problems such as uneven heating, inconsistent deformation and stretching range, hidden dangers of boiler maintenance costs, etc., and achieve the effect of eliminating cracking and air leakage, and eliminating uneven expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

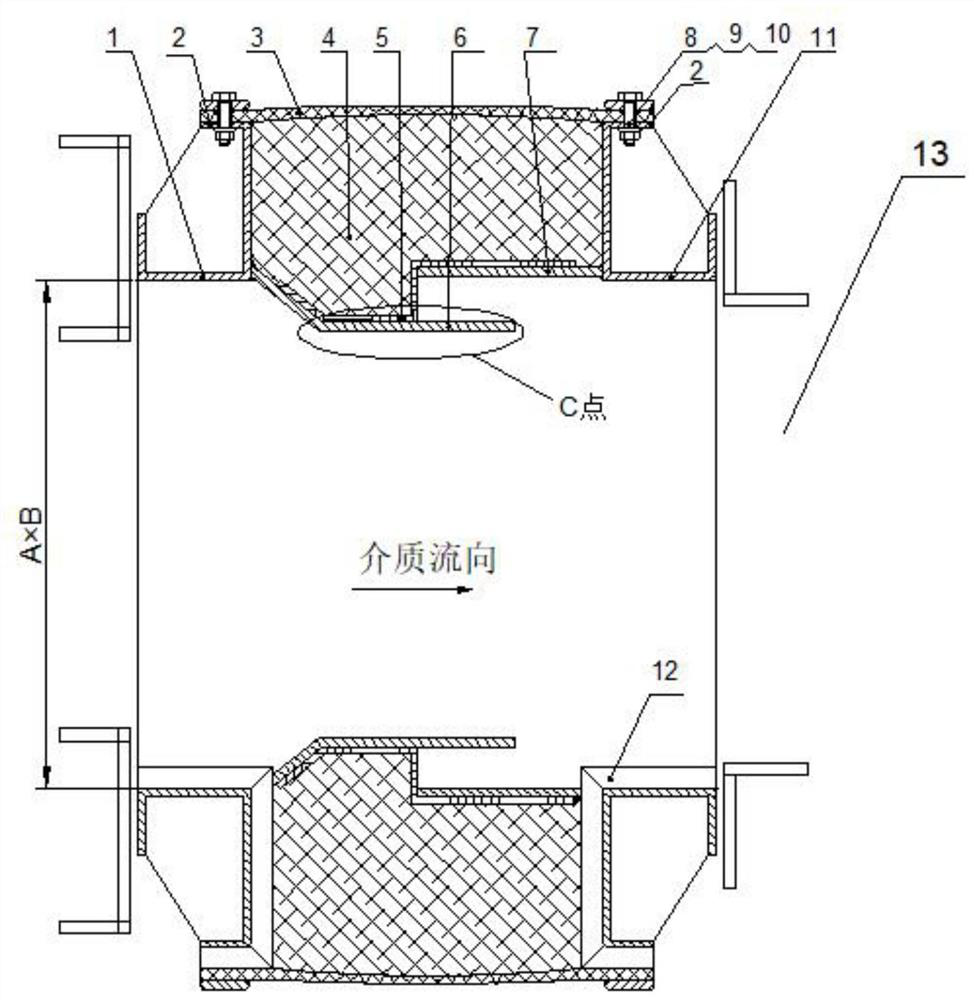

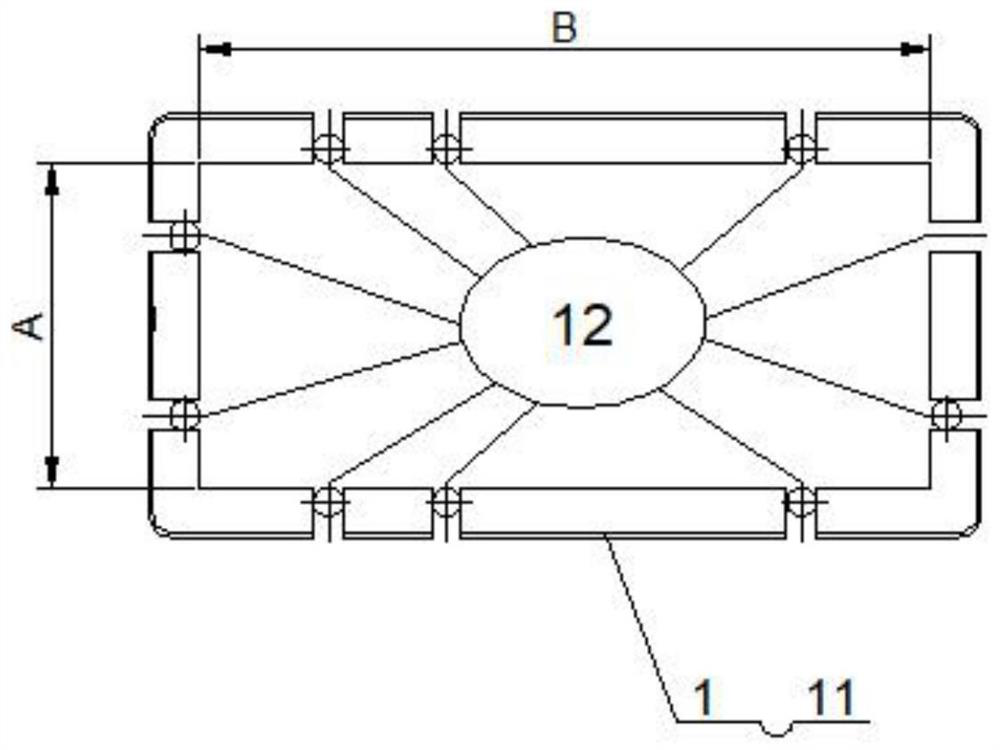

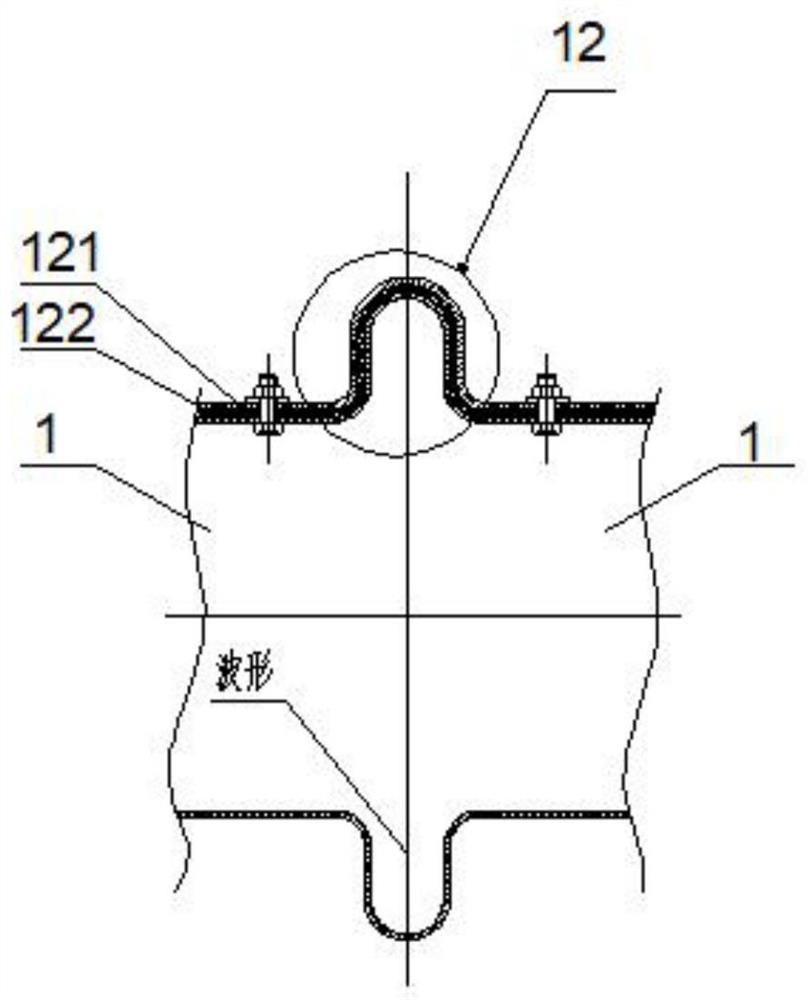

[0021] Such as figure 1 , Figure 6 As shown, a non-metallic expansion joint that solves the uneven expansion of a large-diameter flue. The metal frame 1 and the metal frame 2 11 of the same shape are arranged at both ends of the square non-metallic expansion joint body 13 and arranged symmetrically. The square channel is a high-temperature medium flow channel, and the compression flange 2 that bends outwards at the upper ends of metal frame 1 and metal frame 2 11 is provided with screw holes 101, and the inner side of the lower end of metal frame 1 at the left end is provided with a steel mesh 5 extending to the right , the steel mesh 5 is bent upwards and then stretched to the right, and the lower end of the steel mesh 5 is provided with a lining plate 6, and one end of the lining plate 6 is fixed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com