Multi-segment type exhaust pipe structure

An exhaust pipe, multi-stage technology, applied in the direction of exhaust devices, mufflers, engine components, etc., can solve the problems of large deformation of the exhaust pipe, reduce the extrusion effect of the exhaust pipe gasket, etc., and achieve extended service life Effects of lifespan, reduction in number and types, and elimination of effects of thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings.

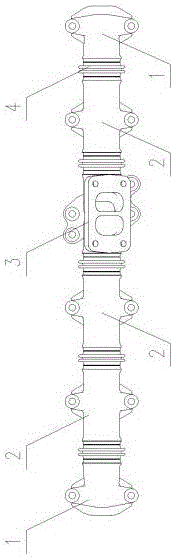

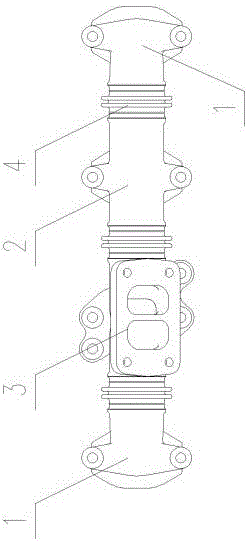

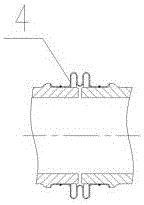

[0016] Multi-stage exhaust pipe structure, including end exhaust pipes 1 located on both sides of the array, several sections of intermediate exhaust pipes 1 are arranged between the two end exhaust pipes 1), and the two end exhaust pipes 1 Also be provided with at least one supercharging exhaust pipe 3 between, on the wall surface of described supercharging exhaust pipe 3, be provided with supercharger air outlet, described supercharging exhaust pipe 3 is arranged on any two adjacent Between the middle exhaust pipes 1, the terminal exhaust pipe 1, the middle exhaust pipe 1, and the booster exhaust pipe 3 are connected by metal bellows 4, and the terminal exhaust pipe 1, the middle exhaust pipe Both ends of the air pipe 1 and the supercharging exhaust pipe 3 are provided with an annular flange, and the axial ends of the metal bellows are pressed against the opposite surfaces o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com