Pure rabbit wool tops drawing frame

A technology of drawing frame and rabbit fur, applied in spinning machine, rolling mechanism, textile and papermaking, etc., can solve the problems of affecting yarn quality, unfavorable drawing, uneven thickness of hair segments, etc. Bar quality, evenness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

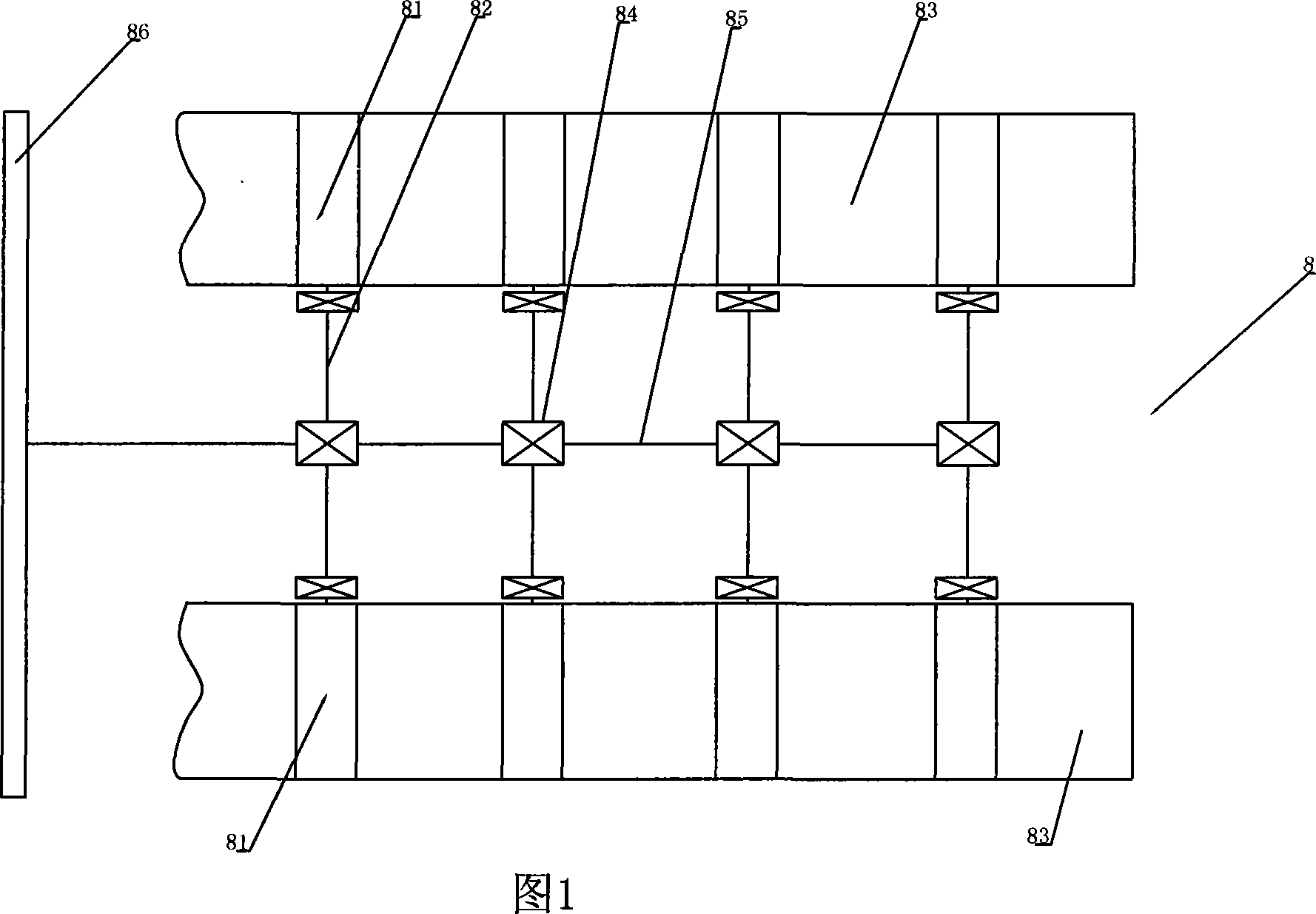

[0023] Referring to Fig. 1, Fig. 5 and Fig. 6, the drawing frame for rabbit fur sliver of the present invention includes a strip guiding mechanism 8, a drafting mechanism 2, a clamping conveying and transverse kneading device 1 and a coiling mechanism 3. Wherein, the drafting mechanism 2 and the coiling mechanism 3 can directly adopt the prior art. The drafting mechanism 2 can adopt the drafting mechanism in the above-mentioned drawing frame, such as adopting one of the two-zone curve drafting techniques with three upper and three lower pressure bars, the coiling mechanism 3 can adopt a carding machine, a wool spinning carding machine Or draw frame coiler, etc.

[0024] The following highlights the innovative part of the guide bar mechanism:

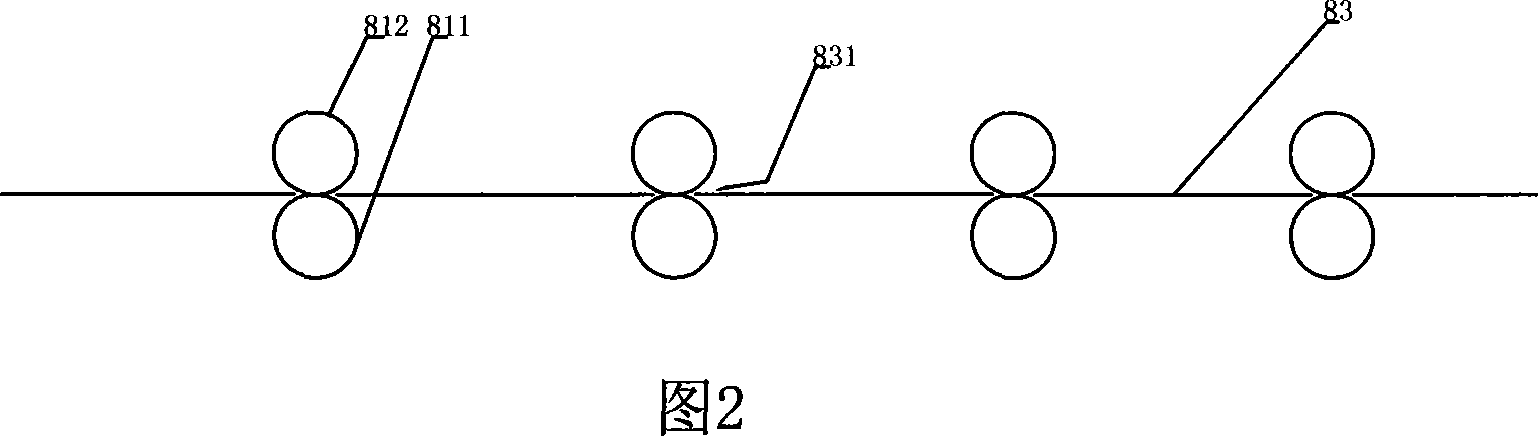

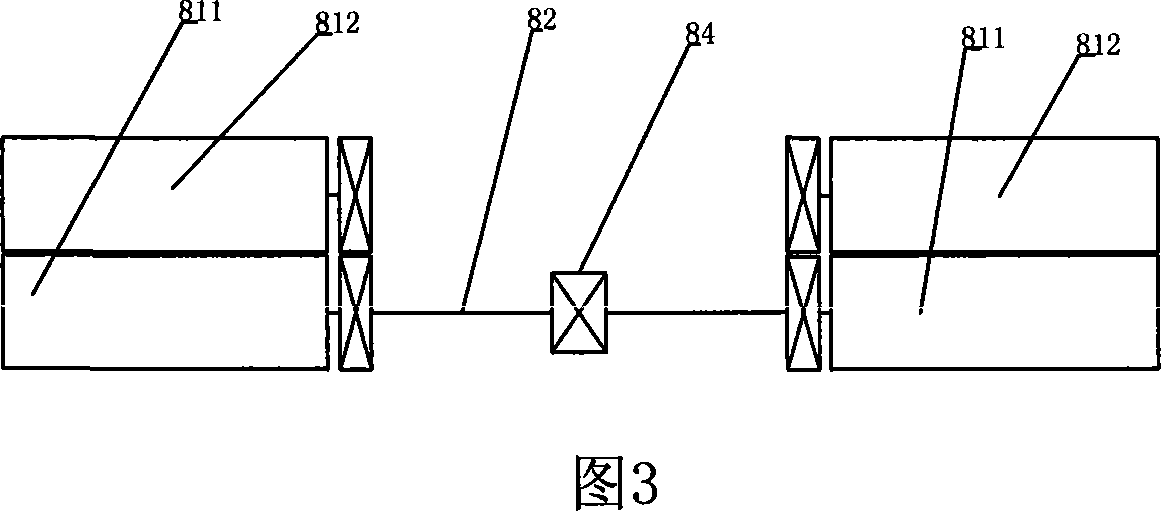

[0025] Focusing on Fig. 1, Fig. 2, Fig. 3 and Fig. 4, on the sliver platform, such as the left sliver platform and the right sliver platform, 4 wool sliver dry conveying roller groups 81 are respectively arranged successively, and each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com