Sagger used for high-temperature firing and preparation method of sagger

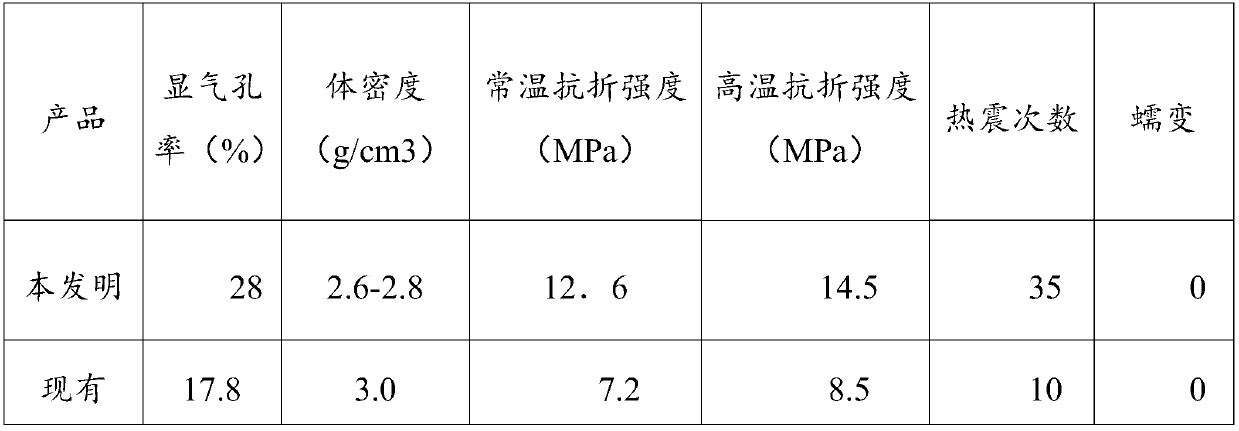

A high-temperature firing and saggar technology, which is applied in the field of high-temperature firing saggar and its preparation, can solve the problems of poor rapid cooling and rapid heat resistance, fast heating and cooling speed, and less thermal shock times of the sagger, and achieve color and Good thermal shock stability, small thermal expansion coefficient, and the effect of improving thermal shock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a sagger for high-temperature firing, which is prepared from the following raw materials: 8 parts of binder or 4.5 parts of water reducer, 15 parts of alumina powder, 17.5 parts of white kaolin powder, 17.5 parts of yellow kaolin powder, and 16.5 parts of quartz powder 20.5 parts, 36 mesh white corundum 20.5 parts, 60 mesh white corundum 20.5 parts, 80 mesh white corundum 20.5 parts, 0-1mm white corundum 20.5 parts, 0.5-1 quartz 22.5 parts, 0.2-0.5mm quartz 22.5 parts, 0.1- 0.2mm quartz 20.5 parts, 0-0.5mm fused mullite 15.5 parts, 0.5-1mm fused mullite 15.5 parts and 1-3mm fused mullite 15.5 parts.

[0041] The preparation method comprises the following steps:

[0042] (1) Carry out magnetic separation to all raw materials, check the impurity iron, and use it after the iron content reaches the standard;

[0043] (2) Mix the alumina powder, kaolin powder, clay powder, white corundum, quartz, mullite, water reducer and water magnetically separat...

Embodiment 2

[0048] The difference between this example and Example 1 is: 1 part of binder, 5 parts of alumina powder, 30 parts of white kaolin powder, 5 parts of yellow kaolin powder, 30 parts of quartz powder, 1 part of 36 mesh white corundum, 60 mesh 40 parts of white corundum, 40 parts of 80 mesh white corundum, 1 part of 0-1mm white corundum, 40 parts of 0.5-1 quartz, 5 parts of 0.2-0.5mm quartz, 40 parts of 0.1-0.2mm quartz, 0-0.5mm 1 part of fused mullite, 30 parts of fused mullite of 0.5-1 mm and 1 part of fused mullite of 1-3 mm.

Embodiment 3

[0050] The difference between this example and Example 1 is: 8 parts of water reducer, 25 parts of alumina powder, 5 parts of white kaolin powder, 30 parts of yellow kaolin powder, 3 parts of quartz powder, 40 parts of 36 mesh white corundum, 60 1 part of white corundum, 1 part of 80 mesh white corundum, 40 parts of 0-1mm white corundum, 5 parts of 0.5-1mm quartz, 40 parts of 0.2-0.5mm quartz, 1 part of 0.1-0.2mm quartz, 0-0.5mm 30 parts of fused mullite, 1 part of fused mullite of 0.5-1mm and 30 parts of fused mullite of 1-3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com