Reaction diffusion connection method of ceramic composite material and metal

A technology of ceramic composite materials and diffusion bonding, which is applied in the field of reactive diffusion bonding of ceramic composite materials and metals, and reactive diffusion bonding of ceramic and metal materials. Mechanical properties, improving thermal shock resistance, and alleviating the effect of mismatch problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

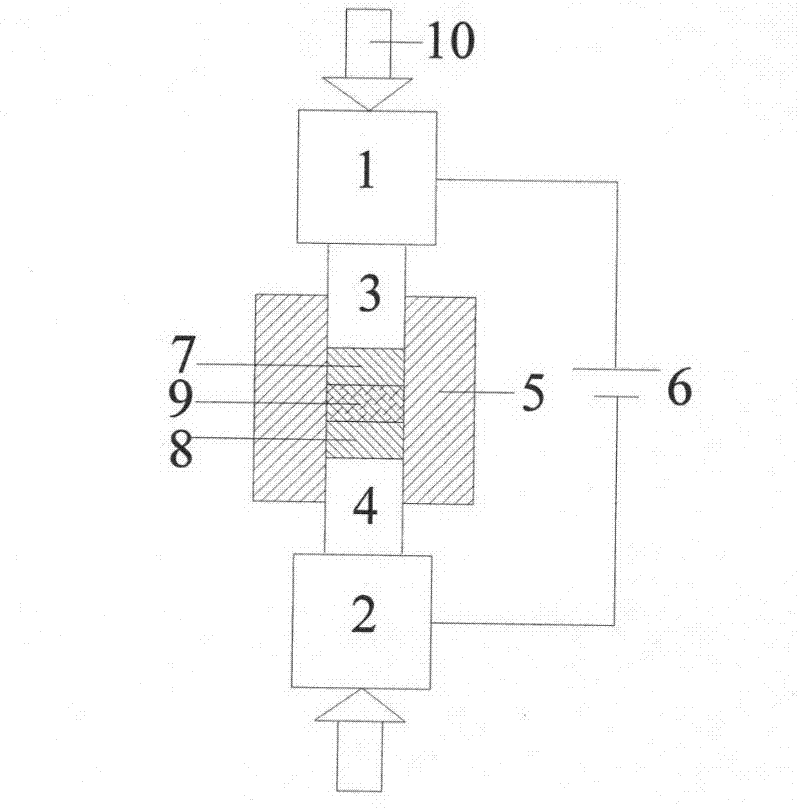

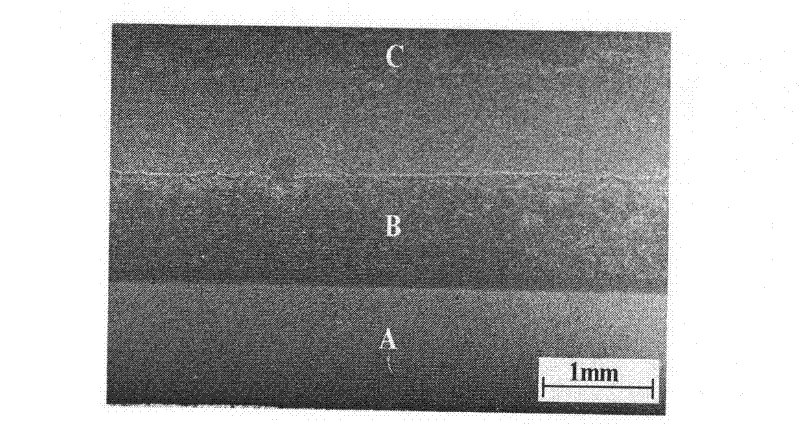

[0023] Embodiment 1: TiB 2 / Ni-Ni 3 Al-Ni connection structure

[0024] TiB 2 / Ni composite ceramics, the Ni content is 10%, the Ni plate thickness is 5mm; the mixed powder is mixed in a molar percentage of 3:1, and the powder particle size is 5-10 μm, according to figure 1 The way shown will TiB 2 / Ni-Ni 3 Al-Ni is placed in the corundum mold between the electrodes, the current is raised to 1300A and kept for 12min, then lowered to 1000A for 5min, and finally the power is turned off, and the sample is cooled to room temperature with the furnace. The vacuum degree in the furnace during the whole process is about 2×10 -4 Pa, apply a unidirectional pressure of 70MPa, take out the sample from the mold after natural cooling, and the shear strength of the connecting piece is 78MPa.

Embodiment approach 2

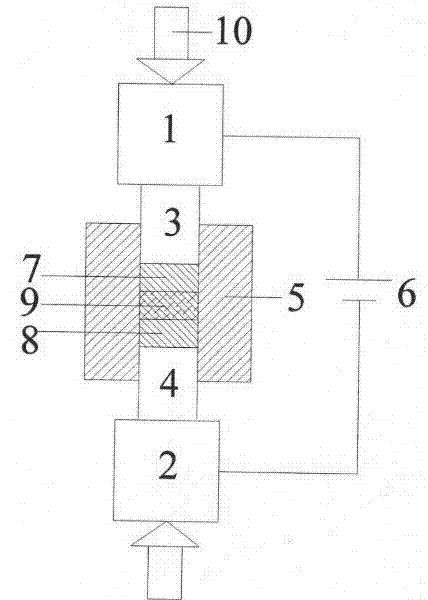

[0025] Embodiment 2: TiC / Ni-TiAl-Ti connection structure

[0026] TiC / Ni composite ceramics, the Ni content is 10%, the thickness of the Ti plate is 5mm; the mixed powder of Ti and Al is mixed at a molar percentage of 1:1, and the particle size of the powder is 5-10 μm, according to figure 1 The method shown puts TiC / Ni-TiAl-Ti in the corundum mold between the electrodes, raises the furnace temperature to 773K, then adjusts the current to 1400A for 15min, slowly drops to 1200A, keeps for 5min, and slowly drops to 750A for 15min 5min; when the reaction reaches the 7th minute, apply a unidirectional pressure of 42.5MPa to the reaction blank until the end of the reaction; finally turn off the power, the sample is cooled to room temperature with the furnace, and the vacuum degree in the furnace is about 2×10 -3 Pa. The sample was taken out from the mold after natural cooling, and the shear strength of the connecting piece was 90MPa.

Embodiment approach 3

[0027] Embodiment 3: TiB 2 / Ni-Ni 3 Al-CrNi alloy connection structure

[0028] TiB 2 / Ni composite ceramics, Ni content 10%, CrNi plate thickness 5mm; Ni 3 Al mixed powder is mixed according to the molar percentage of 1:1, and the particle size of the powder is 5-10 μm, according to figure 1 The way shown will TiB 2 / Ni-Ni 3 Al-Ni is placed in the corundum mold between the electrodes, the current is raised to 1300A and kept for 12min, then lowered to 1000A for 5min, and finally the power is turned off, and the sample is cooled to room temperature with the furnace. The vacuum degree in the furnace during the whole process is about 2×10 -4 Pa, apply a unidirectional pressure of 70MPa, take the sample out of the mold after cooling naturally, and the shear strength of the connector is 80MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com