On-line remote state monitoring and fault analysis diagnosis system of reciprocating compressor

A fault analysis, compressor technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of shutdown and maintenance expenses, failure of compressor failures to be reflected in time, shutdown and production shutdown, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

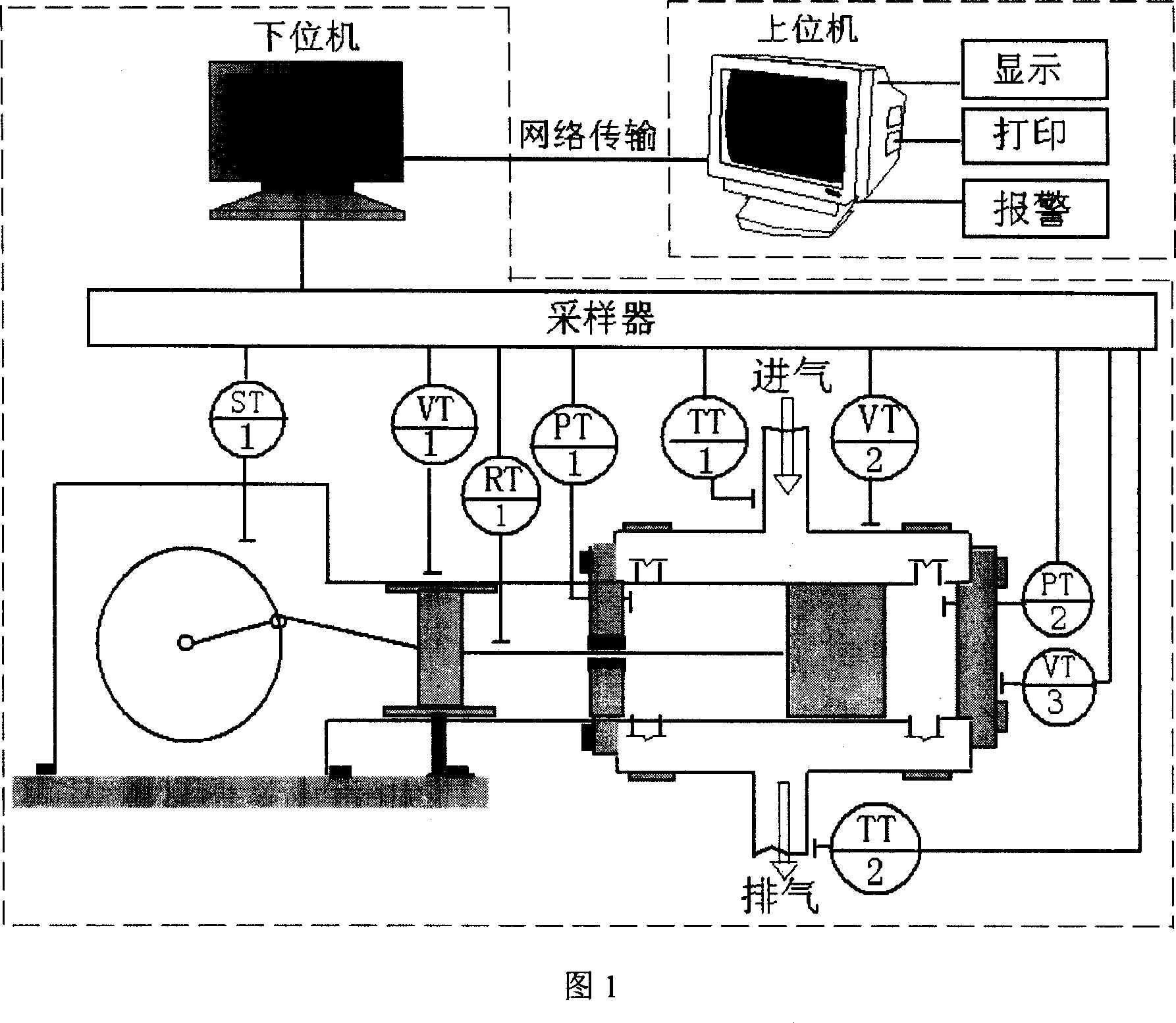

[0015] This system will be further described below with reference to the accompanying drawings.

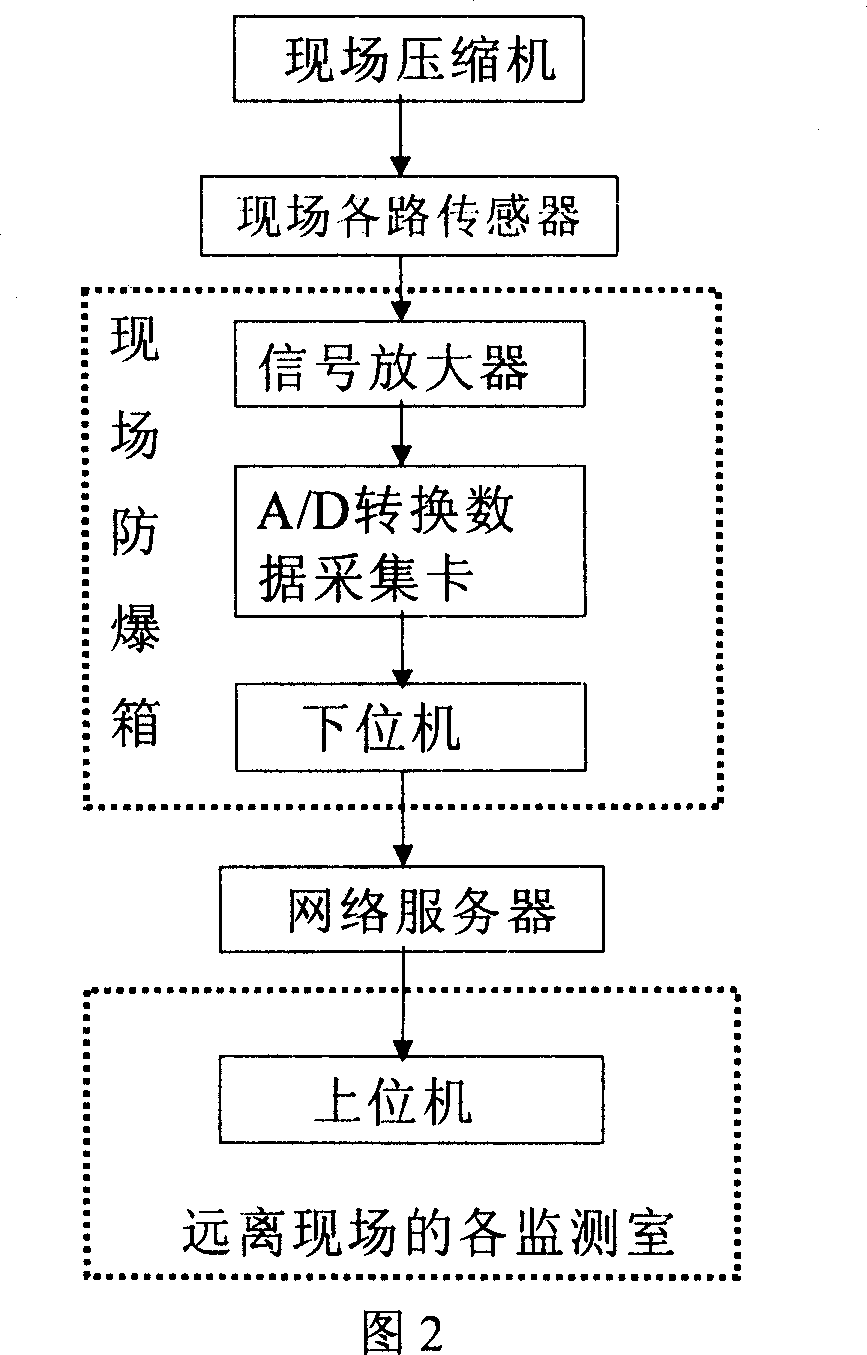

[0016] The hardware of the monitoring system adopts the upper and lower computer structure shown in Figure 2. As the front-end data collector and transmitter of the whole system, the lower computer has special requirements for it. It must have multi-channel A / D conversion, and the sampling speed of each channel and the number of data points for one sampling should be based on the actual operation of the compressor. If the situation changes, by measuring and calculating the running speed of the compressor, the data is collected at equal time intervals in the reciprocating cycle, and the collected data is packaged and sent to the host computer reliably. The special-purpose lower computer developed by the present invention also provides three communication interfaces of RS-232, RS-485 and ethernet, so as to meet the different requirements of industrial sites.

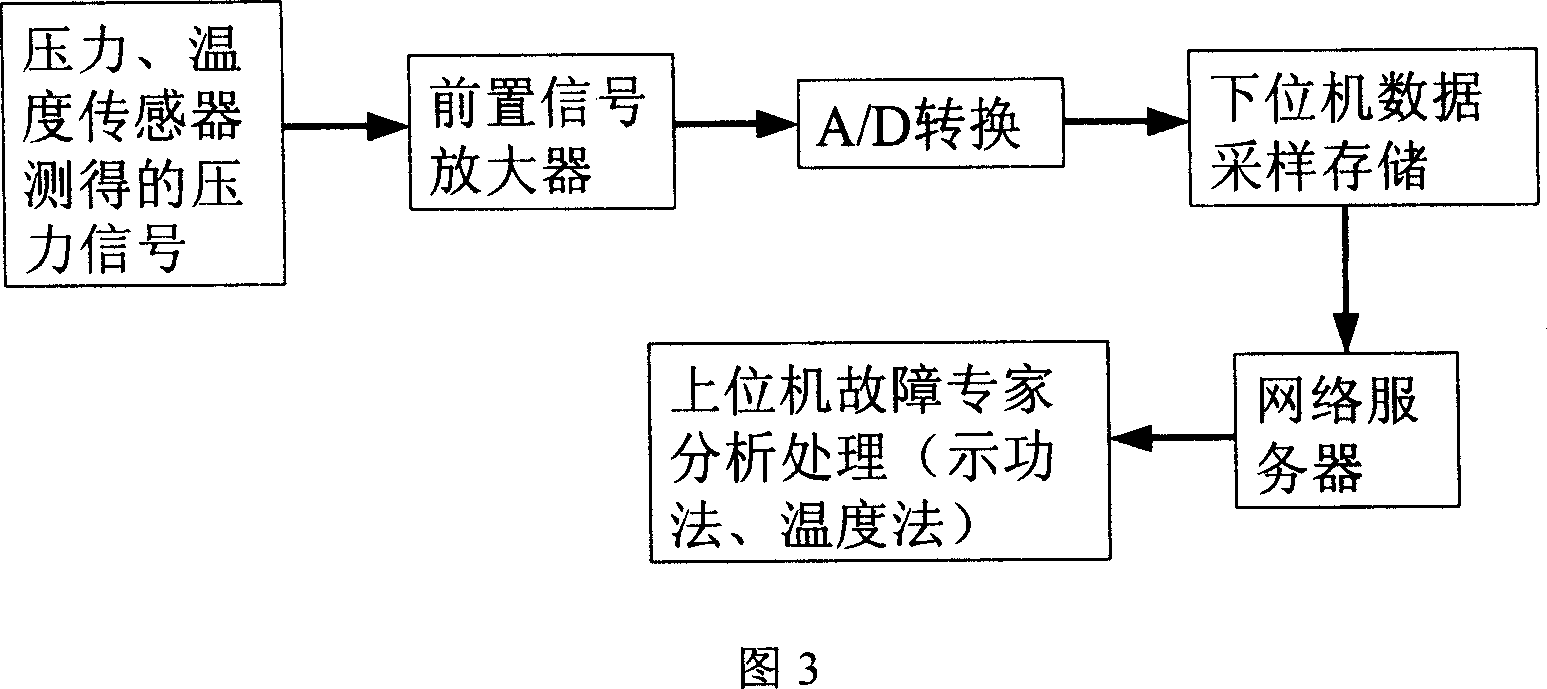

[0017] For the thermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com