Method of distilling and purifying of propolis and special equipment thereof

A purification method and technology of propolis, which is applied in the field of propolis extraction, using ultrasonic waves to extract and purify propolis, can solve the problems of high temperature, low extraction rate, huge investment in equipment, etc., and achieve accelerated dissolution speed, short extraction time and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

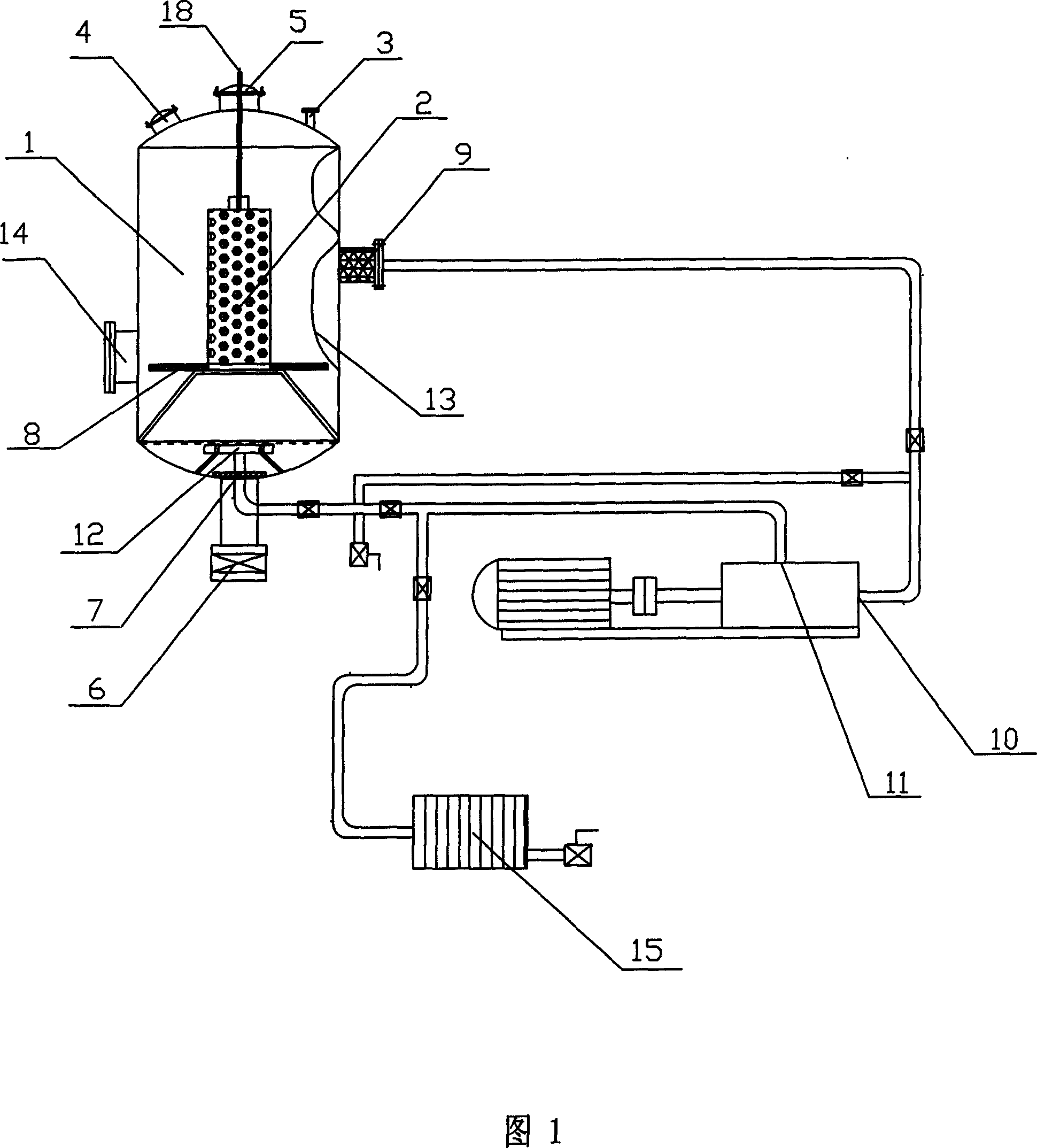

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0027] A method for propolis extraction and purification, comprising the steps of:

[0028] a. After the wool glue is treated at -20-5°C, it is crushed to 14-18 mesh at low temperature;

[0029] b. Use a high-efficiency metal detector to screen out visible metals;

[0030] c. the edible alcohol of propolis and 60~95% (V / V) dissolves batching by weight 1: 4~25;

[0031] d. Use 28-80KHz, 5000-8000KW ultrasonic waves to extract for 60-120 minutes;

[0032] e. The feed liquid is allowed to stand naturally at -5°C, and the supernatant is extracted and filtered through a plate and frame filter;

[0033] f. Remove heavy metals from the supernatant through a resin column, and vacuum concentrate at 45-50°C;

[0034] g. Brew and mature in oak storage tanks for 3 to 12 months.

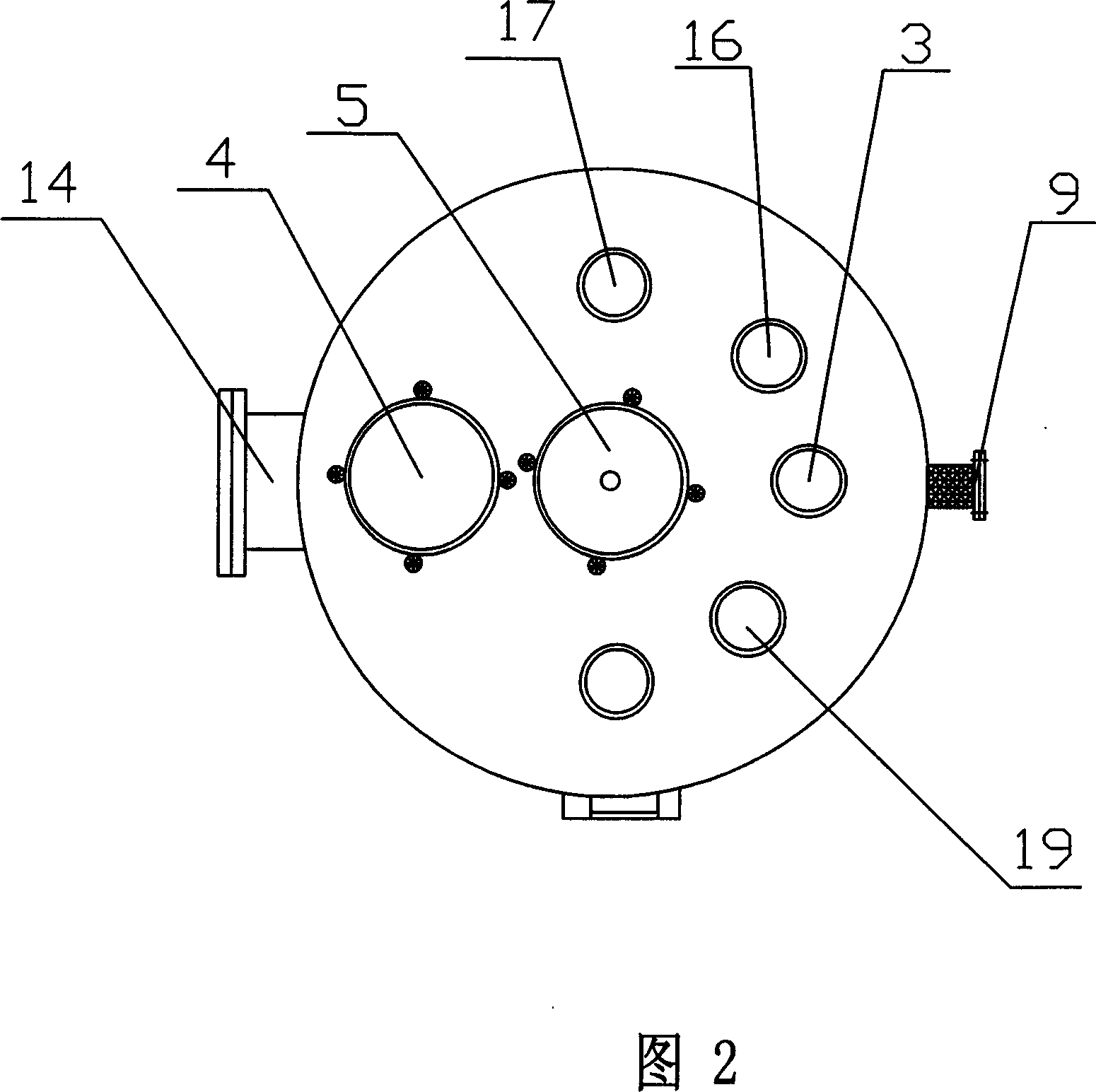

[0035] As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com