Yttrium oxide composition, a method of forming the yttrium oxide composition and a method of forming a yttrium oxide layer using the same

A technology of yttrium oxide and composition, applied in the field of yttrium oxide composition, can solve the problems of low yield, unsuitable for industrial-scale preparation of yttrium oxide, etc., and achieves the effect of low transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

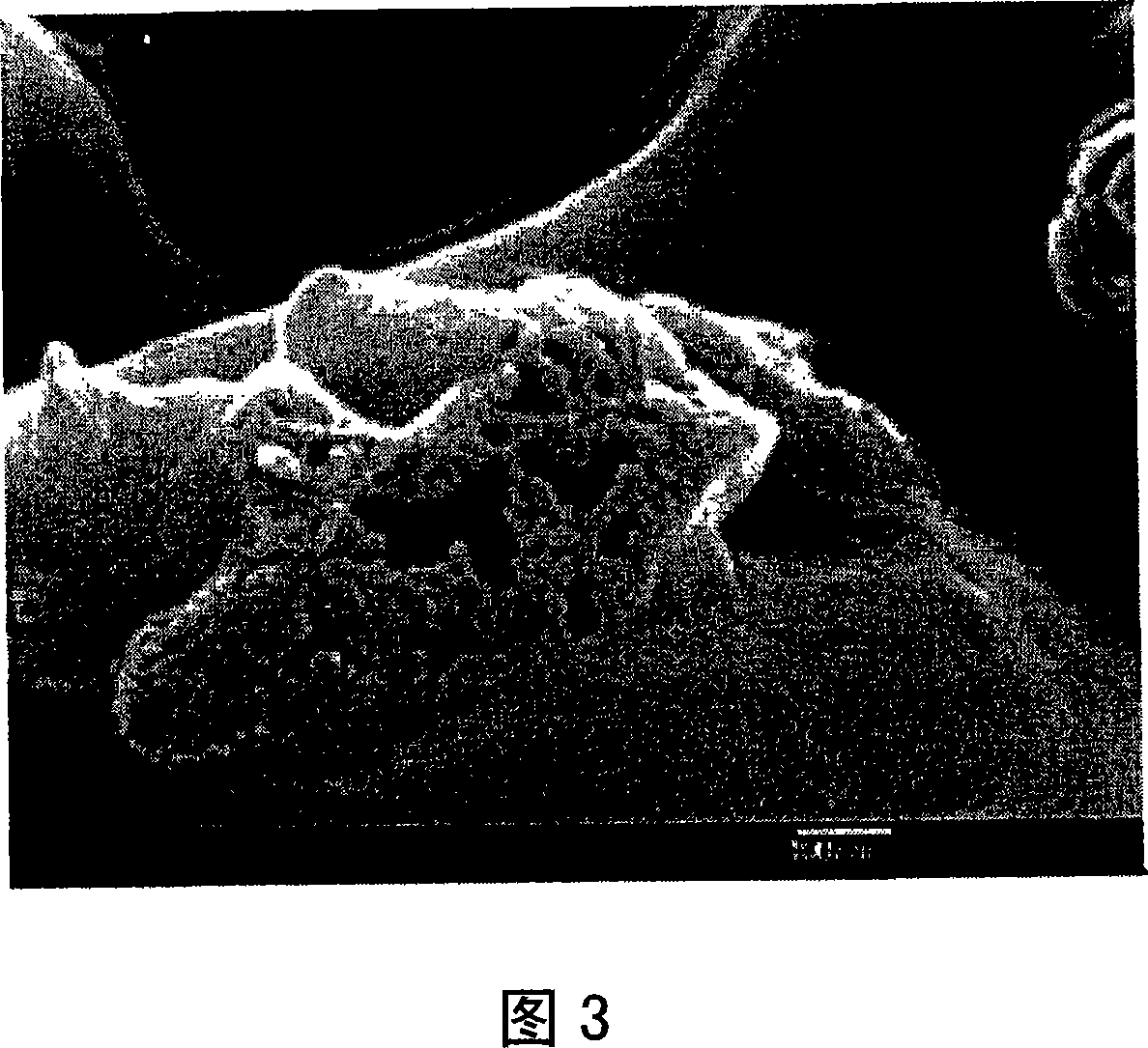

Image

Examples

Embodiment 1

[0060] 36 grams of boric acid (H 3 BO 3 , Sigma, Aldrich) was dissolved in 1 liter of ethanol to prepare 10 mL of boric acid solution. Yttrium nitrate hexahydrate (Y(NO 3 ) 3 -6H 2 O, Sigma, Aldrich) was dissolved in water to prepare 50 ml of 0.065M yttrium nitrate solution. The yttrium salt solution was prepared by mixing the boric acid solution with the yttrium nitrate solution. The ammonium hydroxide solution is slowly added dropwise into the yttrium salt solution to prepare the yttrium oxide composition, and its pH value is controlled at 4.00.

Embodiment 2 to 9

[0062] The yttrium oxide composition was prepared in essentially the same manner as described in Example 1, except for the amount of ammonium hydroxide solution added to the yttrium salt solution. Compositions of Examples 2 to 9 having pH values of 5.79, 5.90, 6.09, 6.15, 6.57, 6.65, 6.98 and 7.06 were prepared by varying the amount of ammonium hydroxide solution added to the yttrium salt solution.

Embodiment 10 to 13

[0064] 36 grams of boric acid (H 3 BO 3 , Sigma, Aldrich) was dissolved in 1 liter of ethanol to prepare 10 mL of boric acid solution. Yttrium nitrate hexahydrate (Y(NO 3 ) 3 -6H 2 O, Sigma, Aldrich) was dissolved in water to prepare 50 ml of 0.47M yttrium nitrate solution. The yttrium salt solution was prepared by mixing the boric acid solution with the yttrium nitrate solution. Compositions of Examples 10 to 13 having pH values of 5.90, 6.37, 6.50 and 6.63 were prepared by varying the amount of ammonium hydroxide solution added to the yttrium salt solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com