Preparation method of naphthalene series dehydragent and special equipment thereof

The technology of a naphthalene-based water-reducing agent and special equipment is applied to the production and preparation process of concrete admixtures for construction and the field of special equipment, and can solve the problems of high surface temperature of the reaction kettle, damage to the service life of equipment, time-consuming steam, and the like. Achieve the effect of reducing hot steam consumption, improving equipment life and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

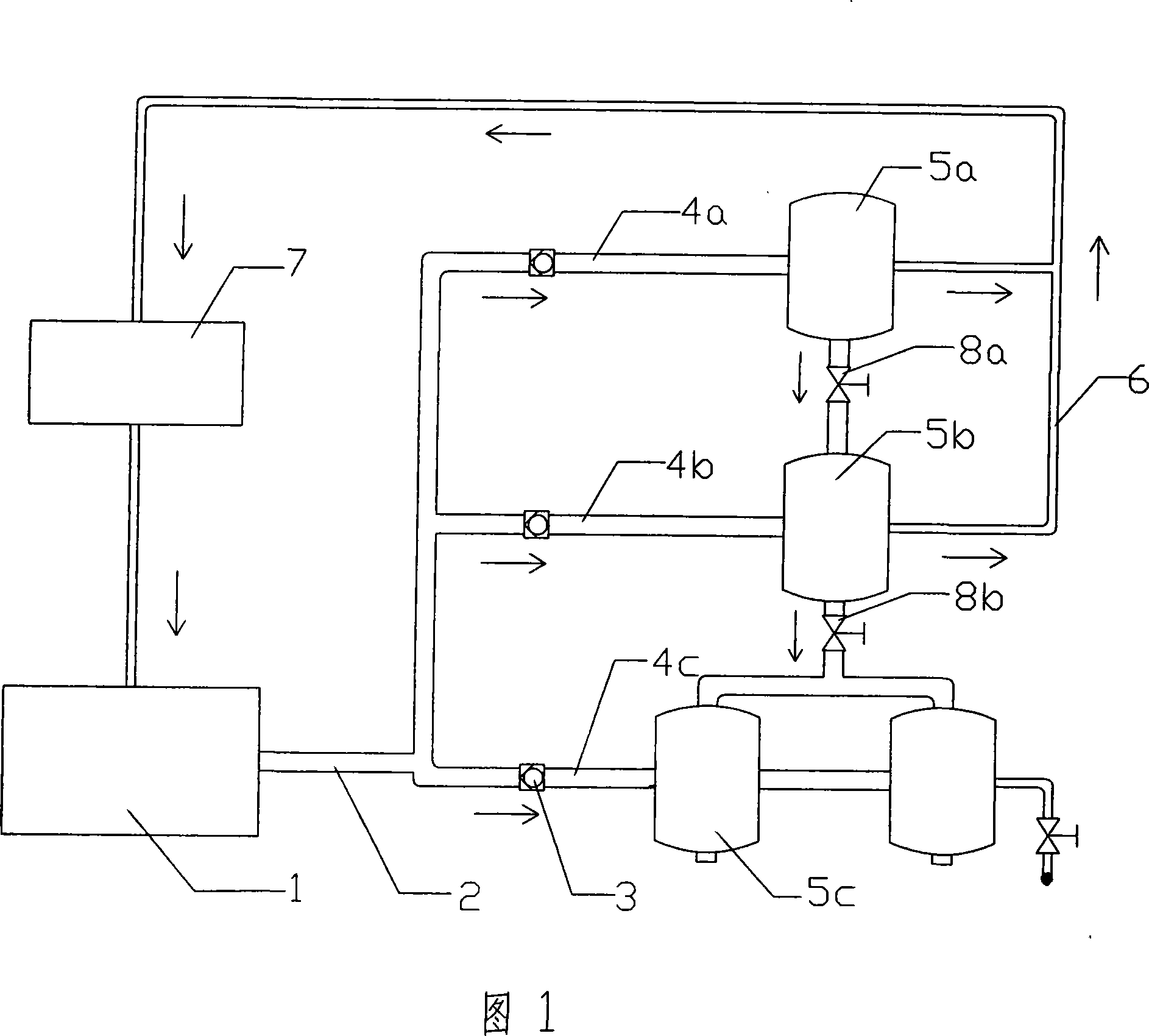

[0018] The special equipment described in the equipment of the present invention is shown in Figure 1, including special-purpose naphthalene melting reactor 5a, special-purpose sulfonation reactor 5b, special-purpose hydrolysis and condensation reactor 5c, and are sequentially arranged and connected in upper, middle and lower layers; Control valves (8a, 8b) are provided on the connecting pipelines between the melting naphthalene reactor 5a, the sulfonation reactor 5b, and the condensation reactor 5c, thereby transferring materials from top to bottom by gravity. In the specific installation, each special reactor can be placed on different floors, and the floor boards are used to support the reactors at different levels. The special-purpose naphthalene melting reactor 5a can be an ordinary iron reactor, which is low in cost and can fully meet the technological needs. The special sulfonation reaction kettle 5b and the special hydrolysis and condensation reaction kettle 5c can be ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap