Cigarette package and manufacturing method of the same

A cigarette and packaging technology, applied in the field of cigarette packaging and its manufacturing, can solve the problems of cigarette bundle aroma and adverse effect on flavor, and achieve the effect of prolonging the shelf life and maintaining the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

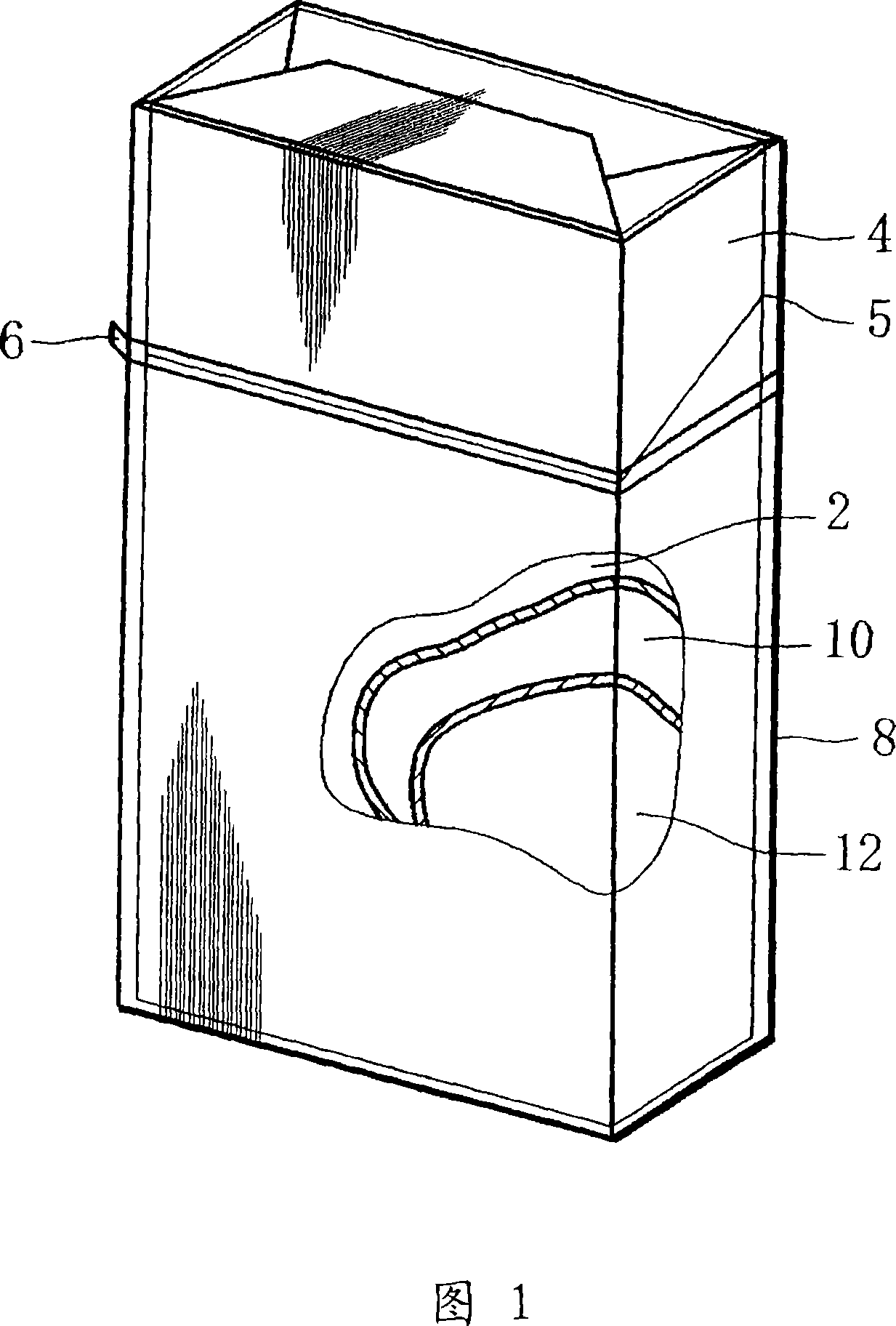

[0034] Fig. 1 shows a cigarette pack of a first embodiment.

[0035] The cigarette package has a hinged lid-type outer box 2 formed by folding a paper outer material. The upper part of the outer box 2 forms a cover 4, and the cover 4 is connected to the back of the outer box 2 through a self-forming hinge 5. The self-forming hinge 5 allows the cover 4 to rotate. When the cover 4 is rotated around the self-folding hinge 5 from the state shown in FIG. 1 , the outer box 2 is opened. Furthermore, the outer box 2 is wrapped with a transparent film 8 having an unsealing tape 6 .

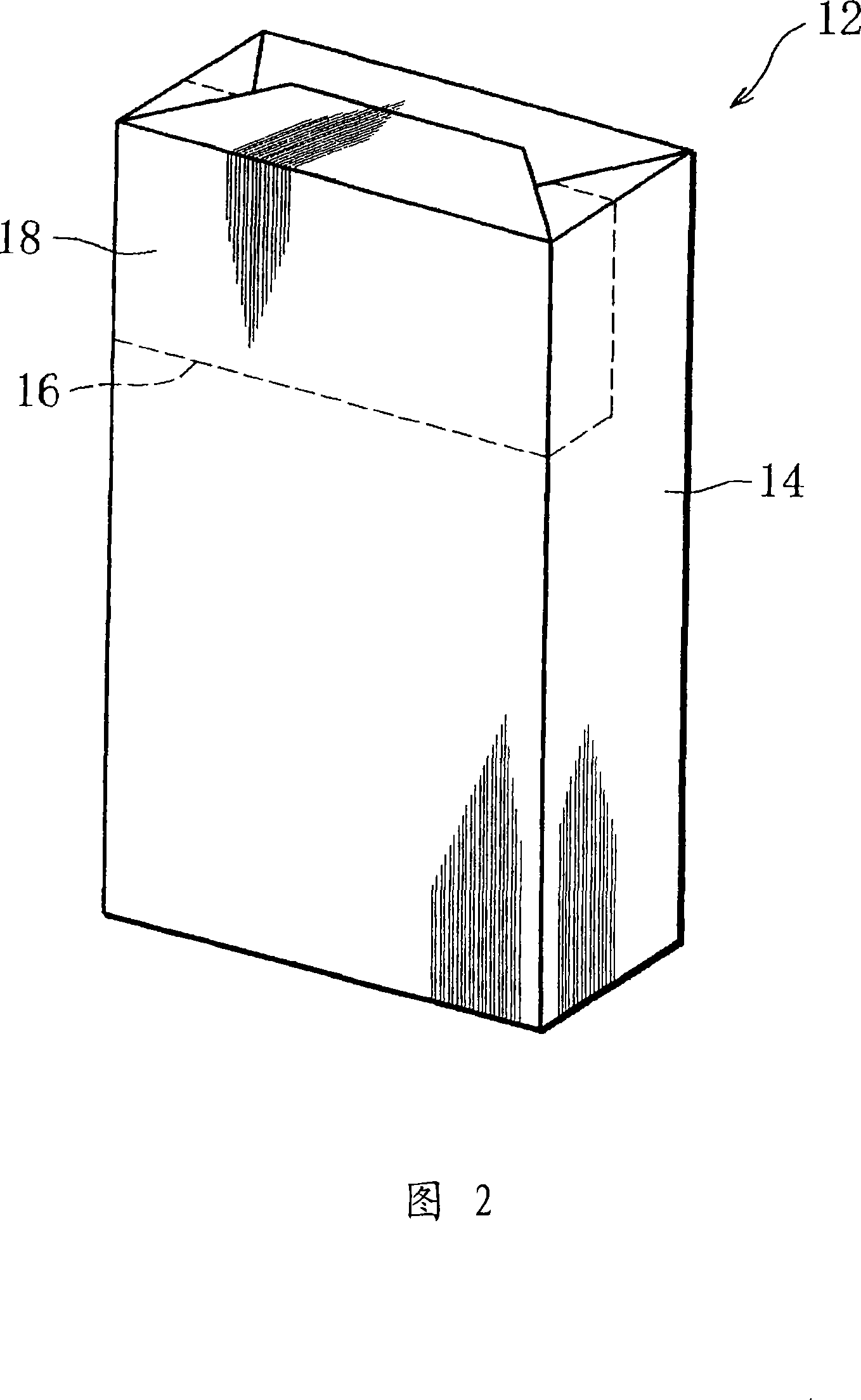

[0036] The outer box 2 accommodates the inner box 10 inside, and accommodates the inner box 10 in a sealed state of the inner package 12 shown in FIG. 2 . The inner pack 12 includes, for example, a bundle of 20 filter cigarettes (not shown) and a soft aluminum-coated paper 14 that wraps the bundle of cigarettes. The aluminized paper 14 is first wound into a U shape around the cigarette bundle, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com