Process of extracting side salt from desulfurized liquid

A technology of desulfurization liquid and auxiliary salt, which is applied in the direction of liquid washing gas purification, etc., can solve the problems of waste of new water resources, non-conformity with circular economy and clean production, and white loss, so as to increase benefits, achieve significant effects of circular economy, and realize circular The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

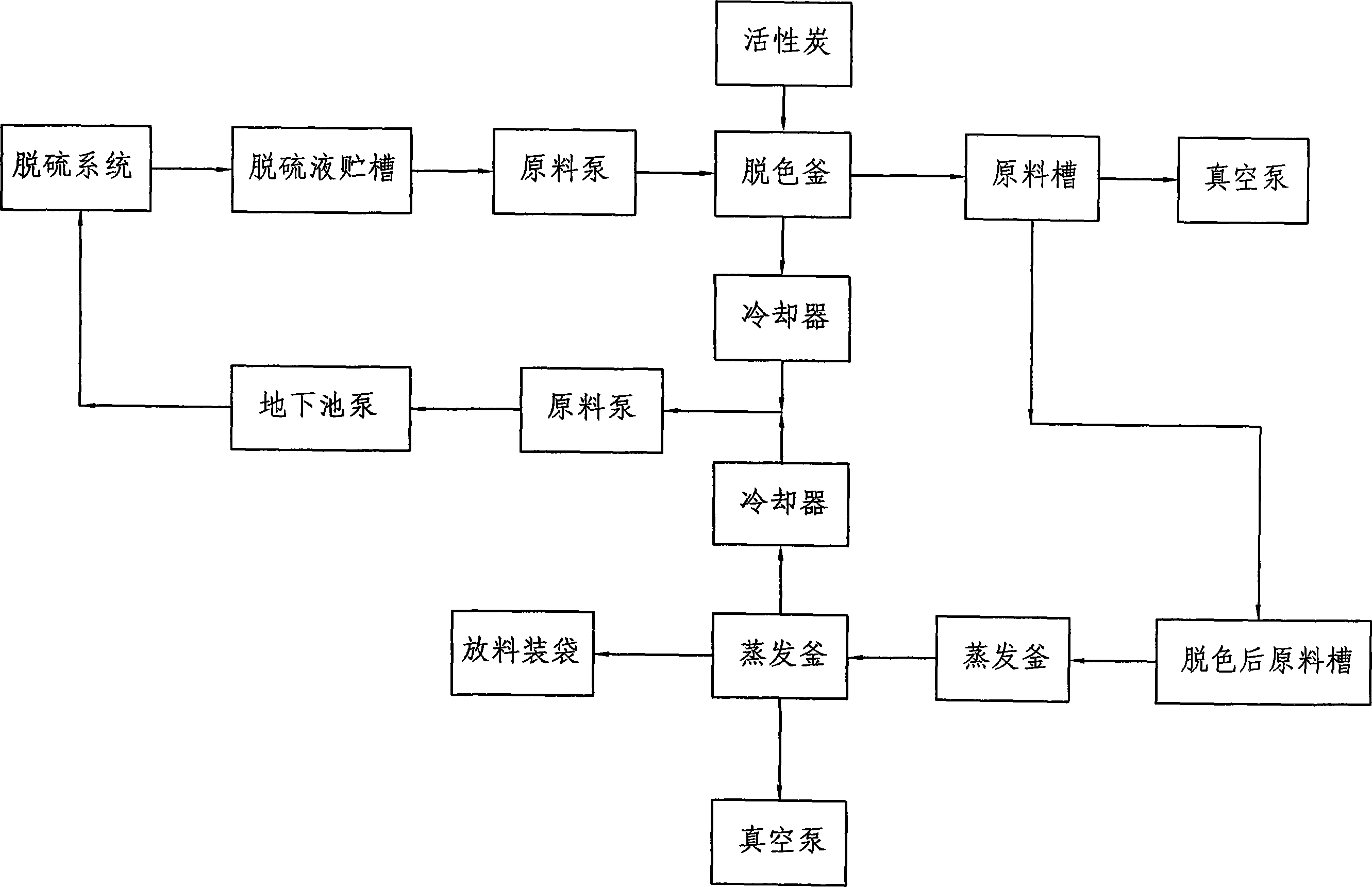

[0017] As shown in the picture.

[0018] After the desulfurization system has been in operation for a period of time, the auxiliary salt in the system will gradually increase, and when it rises to a certain level, it will affect the absorption of hydrogen sulfide and the formation of sulfur foam. In order to reduce the auxiliary salt in the desulfurization liquid, the part of the desulfurization liquid in the two wet desulfurization operations is led to the desulfurization liquid storage tank, and the desulfurization liquid is sent to the salt extraction station through self-pressure or pumps.

[0019] The desulfurization liquid is left to stand in the desulfurization liquid storage tank for 24 hours, and the time can be controlled between 22-26 hours. The insoluble matter in the desulfurization liquid is separated by precipitation, and then sent to the decolorization kettle through the raw material pump.

[0020] In the decolorization kettle, add activated carbon for decolori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com