Two-lay machine-knitted structure textile type artificial blood vessel

An artificial blood vessel, textile-type technology, applied in the direction of catheters, etc., to achieve the effect of tight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

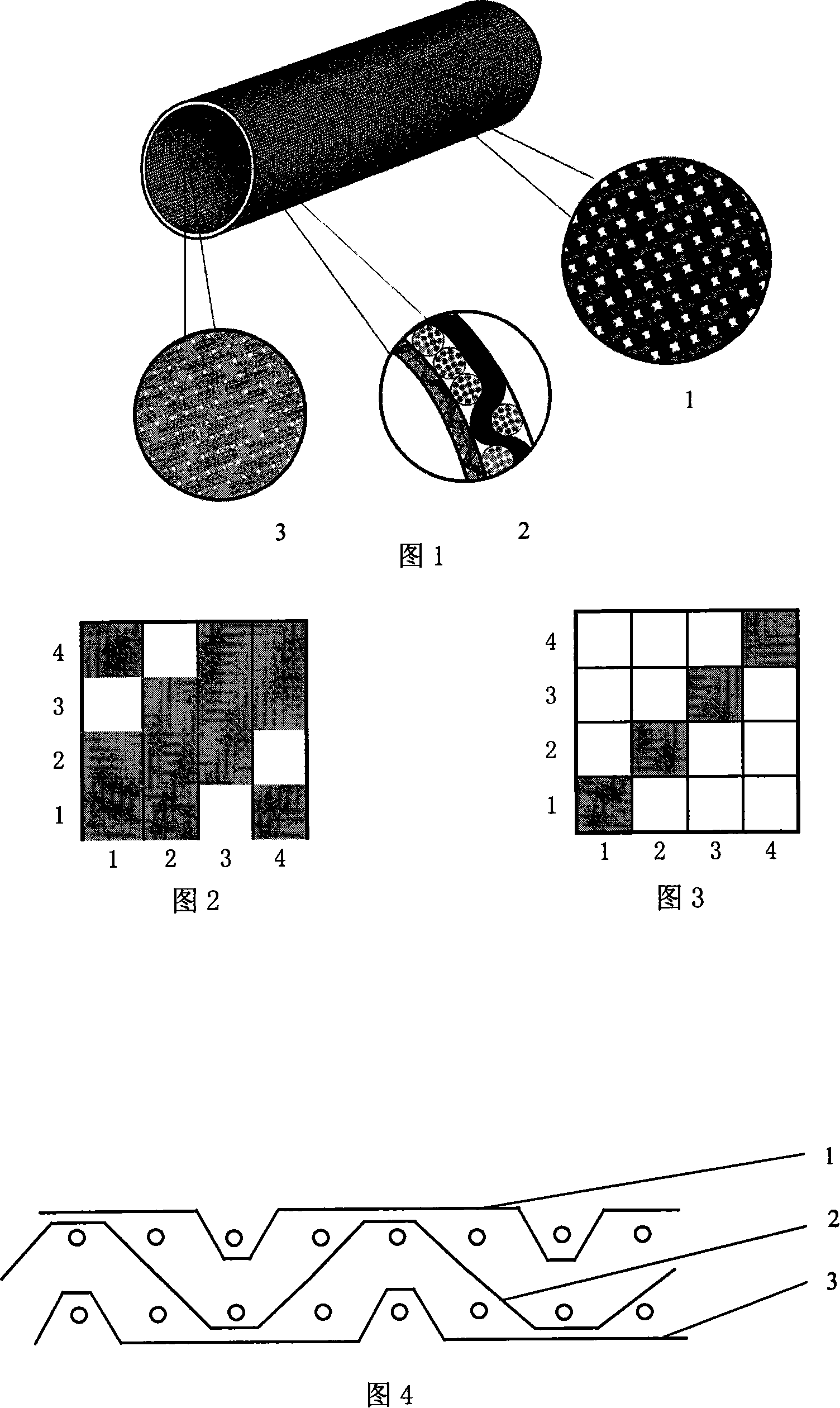

[0020] The woven structure of the outer layer is 3 / 1 twill weave, as shown in Figure 2, using 300dtex / 250f polyester fiber filaments as warp yarns, and 300dtex / 250f polyester fiber filaments as weft yarns; the inner layer woven structure is 1 / 3 twill weave , see Fig. 3, make warp with 30dtex / 24f polyester filament, 30dtex / 24f polyester filament make weft. The outer yarn and the inner yarn are interwoven through the binder yarn, see Figure 4.

[0021] Tubular fabrics are woven on shuttle looms. The warp density of the outer layer woven fabric is 400 threads / 10cm, and the weft density is 400 threads / 10cm. The warp density of the inner fabric is 1000 threads / 10cm, and the weft density is 1000 threads / 10cm.

[0022] The water permeability of the outer layer is 1100ml / cm 2 ·min·16kPa, the water seepage of the inner layer is 280ml / cm 2 · min · 16kPa.

Embodiment 2

[0024] The woven structure of the outer layer is 3 / 1 twill weave, as shown in Figure 2, using 300 dtex / 250f polyester fiber filaments as warp yarns and 300dtex / 250f polyester fiber filaments as weft yarns; the inner layer woven structure is 1 / 3 twill weave Organization, see Fig. 3, make warp with 30dtex / 24f polyester filament, 30dtex / 24f polyester filament make weft. The outer yarn and the inner yarn are interwoven through the binder yarn, see Figure 4.

[0025] Tubular fabrics are woven on shuttle looms. The warp density of the outer layer woven fabric is 400 threads / 10cm, and the weft density is 400 threads / 10cm. The warp density of the inner fabric is 1000 threads / 10cm, and the weft density is 1000 threads / 10cm.

[0026] The water permeability of the outer layer is 1200ml / cm 2 ·min·16kPa, the water seepage of the inner layer is 290ml / cm 2 · min · 16kPa.

Embodiment 3

[0028] The woven structure of the outer layer is 3 / 1 twill weave, as shown in Figure 2, using 300dtex / 250f polyester fiber filaments as warp yarns, and 300dtex / 250f polyester fiber filaments as weft yarns; the inner layer woven structure is 1 / 3 twill weave , see Fig. 3, make warp with 30dtex / 24f polyester filament, 30dtex / 24f polyester filament make weft. The outer yarn and the inner yarn are interwoven through the binder yarn, see Figure 4.

[0029] Tubular fabrics are woven on shuttle looms. The warp density of the outer layer woven fabric is 400 threads / 10cm, and the weft density is 400 threads / 10cm. The warp density of the inner fabric is 1000 threads / 10cm, and the weft density is 1000 threads / 10cm.

[0030] The water permeability of the outer layer is 1300ml / cm 2 ·min·16kPa, the water seepage of the inner layer is 300ml / cm 2 · min · 16kPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com