Capacitance type micro mechanical temperature sensor for multi-layer beam structure

A technology of capacitive micromachines and temperature sensors, which is applied to thermometers, thermometers, instruments, etc. that use electric/magnetic elements that are directly sensitive to heat, can solve problems such as application limitations, poor consistency, and large volume, and achieve increased area, The effect of increasing the amount of variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

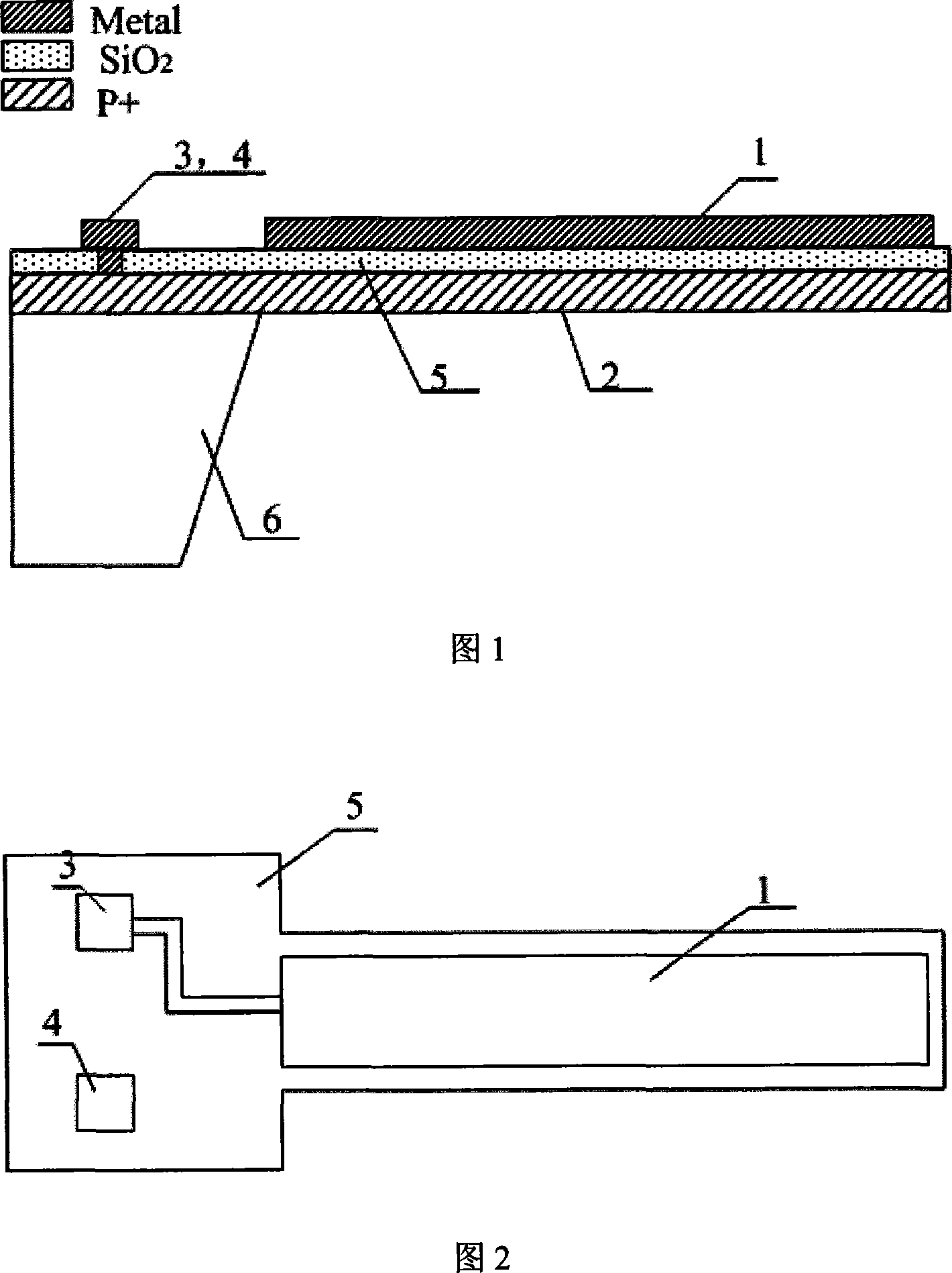

[0008] The present invention is a multi-layer beam structure capacitive temperature sensor for transmitting temperature signals. The sensor consists of an upper capacitor plate 1, a lower capacitor plate 2 and a first lead 3 and a second lead 4 connected to the capacitor plates. The upper capacitor plate 1 and the lower capacitor plate 2 are conductive films, and the insulating dielectric film 5 is filled between the two conductive films. The first lead 3 and the second lead 4 correspond to the upper capacitor plate 1 and the lower lead respectively. The capacitor plates 2 are connected, the lower capacitor plate 2 is arranged on the substrate 6 , and a cavity is arranged under the lower capacitor plate 2 . The conductive film of the upper capacitor plate 1 is a metal film, and the conductive film of the lower capacitor plate 2 is P + layer, and the insulating dielectric film 5 is silicon dioxide.

[0009] When the temperature of the sensor capacitance of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com