Low g value capacitive MEMS accelerometer and modal localization measurement circuit thereof

An accelerometer, capacitive technology, applied in the direction of velocity/acceleration/impact measurement, acceleration measurement, measurement device, etc., can solve the problems of limited capacitance change, insufficient, difficult to meet the microgravity measurement, etc. Effect of Capacitance Value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

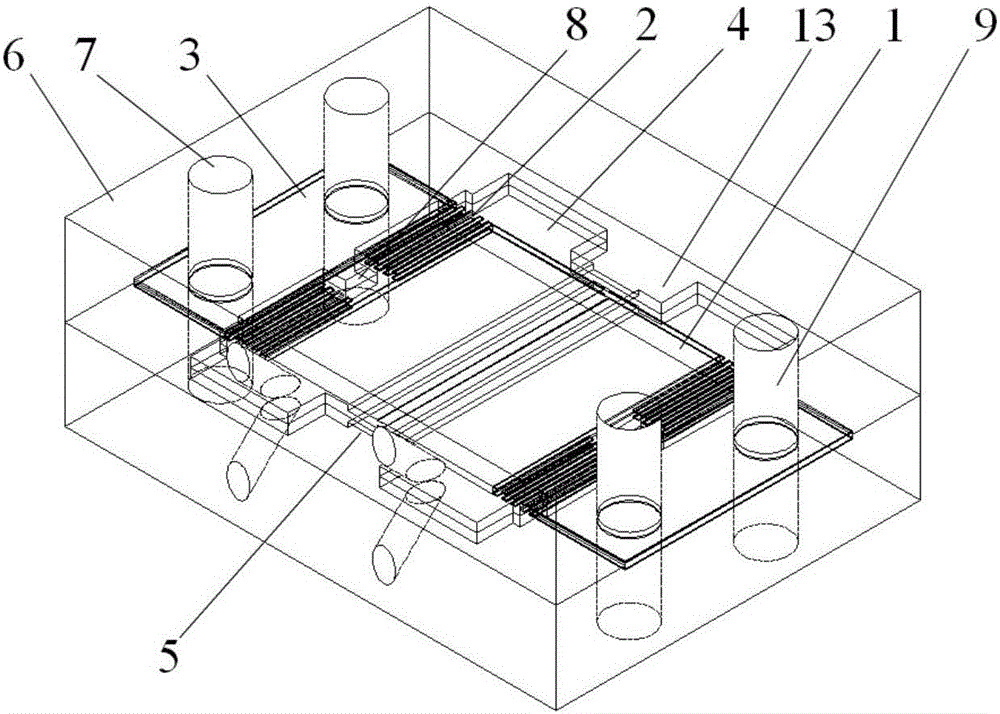

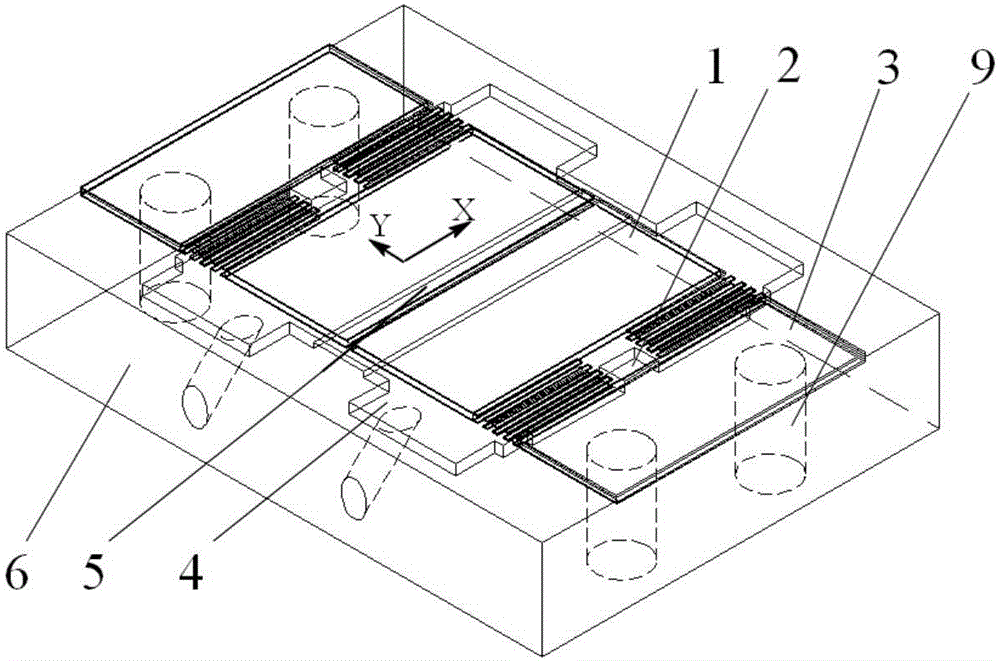

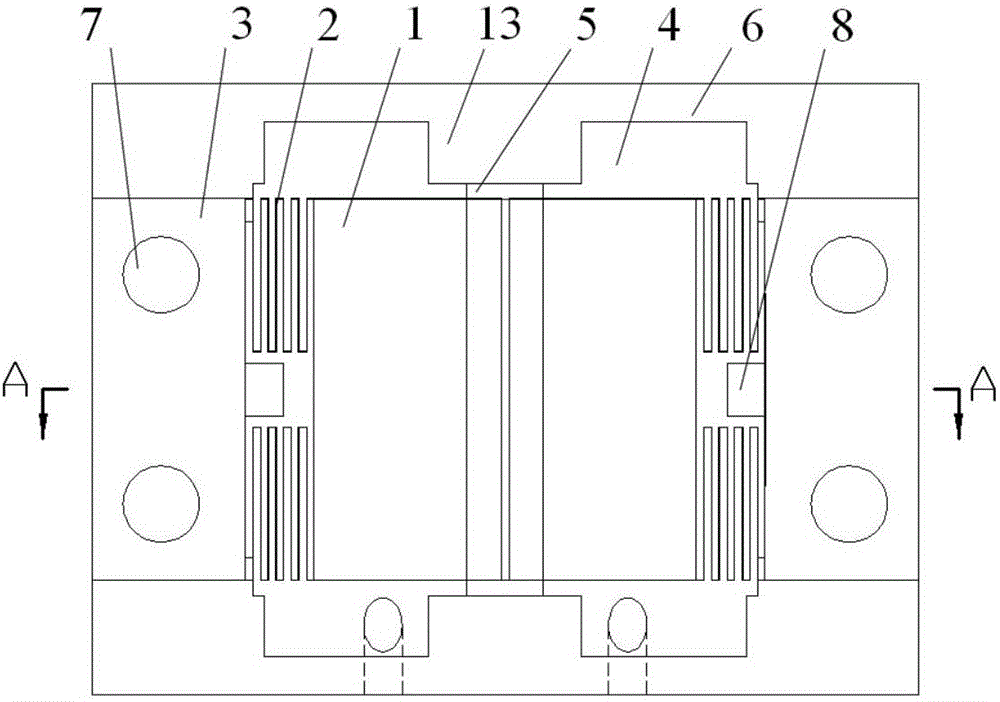

[0045] The technical scheme adopted in the present invention is: a MEMS capacitive acceleration sensor. The acceleration sensor chip includes a spring mass system and a pair of bases 6 made of glass, the spring mass system is packaged between the pair of bases and suspended.

[0046] The spring mass system is integrally processed, including a mass block 1 and a spring 2, the mass block 1 is processed by a silicon substrate 10, the thickness of the silicon substrate is 30 μm, and the silicon substrate 10 is divided into three parts by a pair of springs 2 , are respectively: the fixed end 3 of the mass block at both ends and the mass block in the middle, and the spring 2 is located between one of the fixed ends of the mass block and the mass block, forming the fixed end of the mass block / spring / mass block / spring / mass block fixed end structure.

[0047] The spring 2 is a serpentine spring, and the mass block 1 is suspended in the air and supported by the serpentine spring 2, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com