Column structure dual-wheel foot driving linear ultrasonic motor and electric exciting manner

A linear ultrasonic motor and cylinder technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of small motor output force, low efficiency, and no comparison Solve problems such as fixing methods to achieve the effect of excellent output characteristics of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

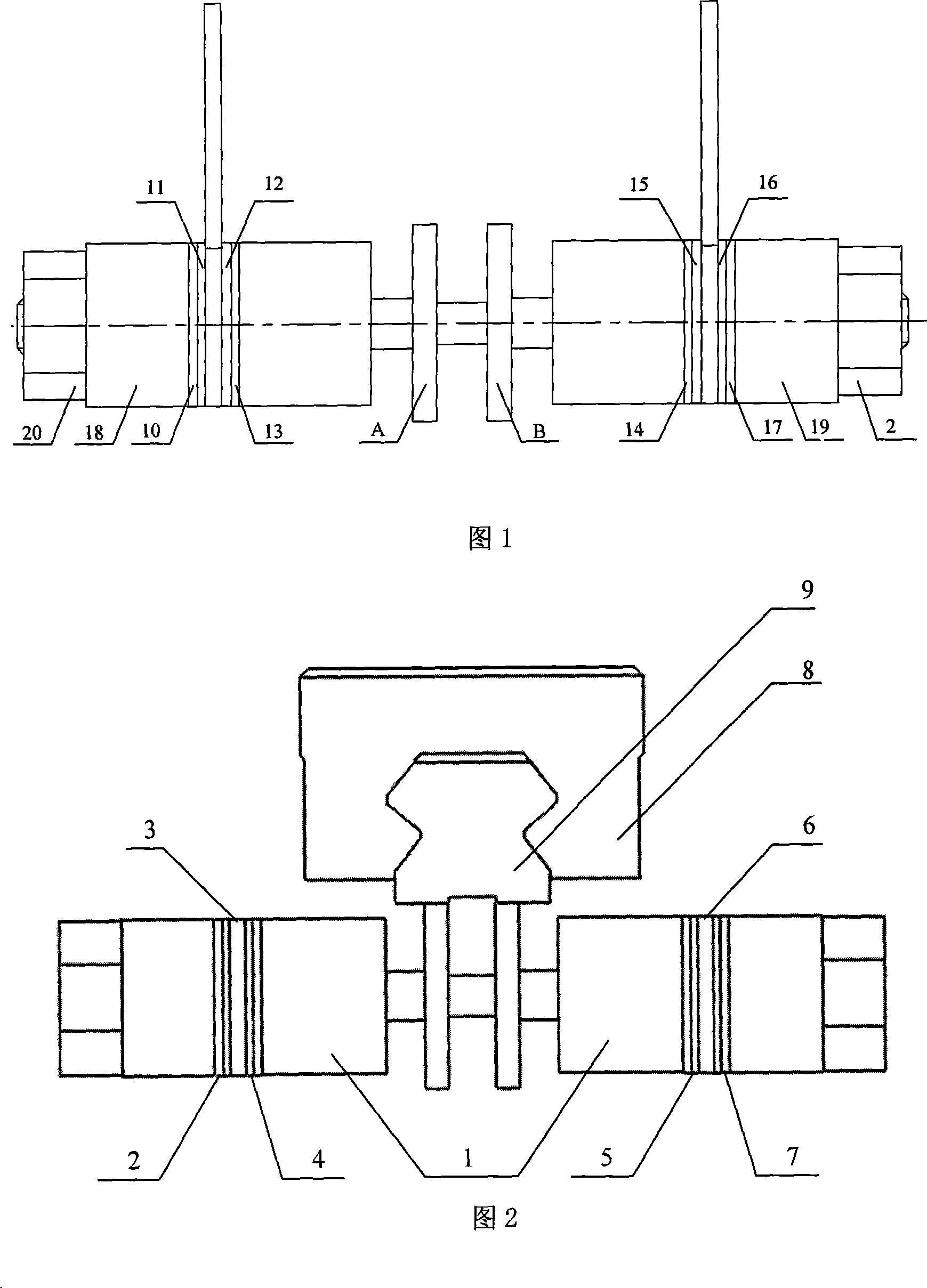

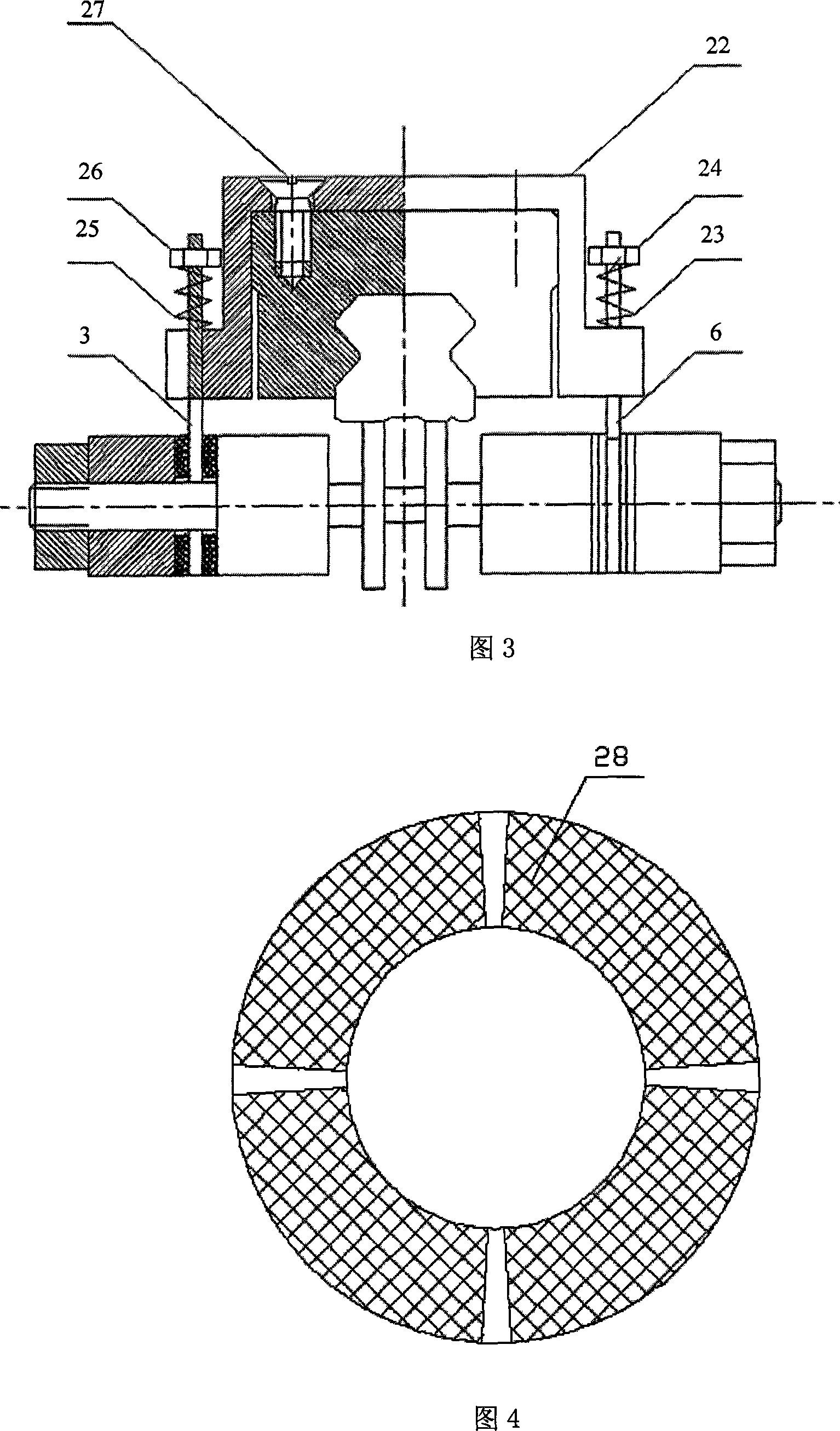

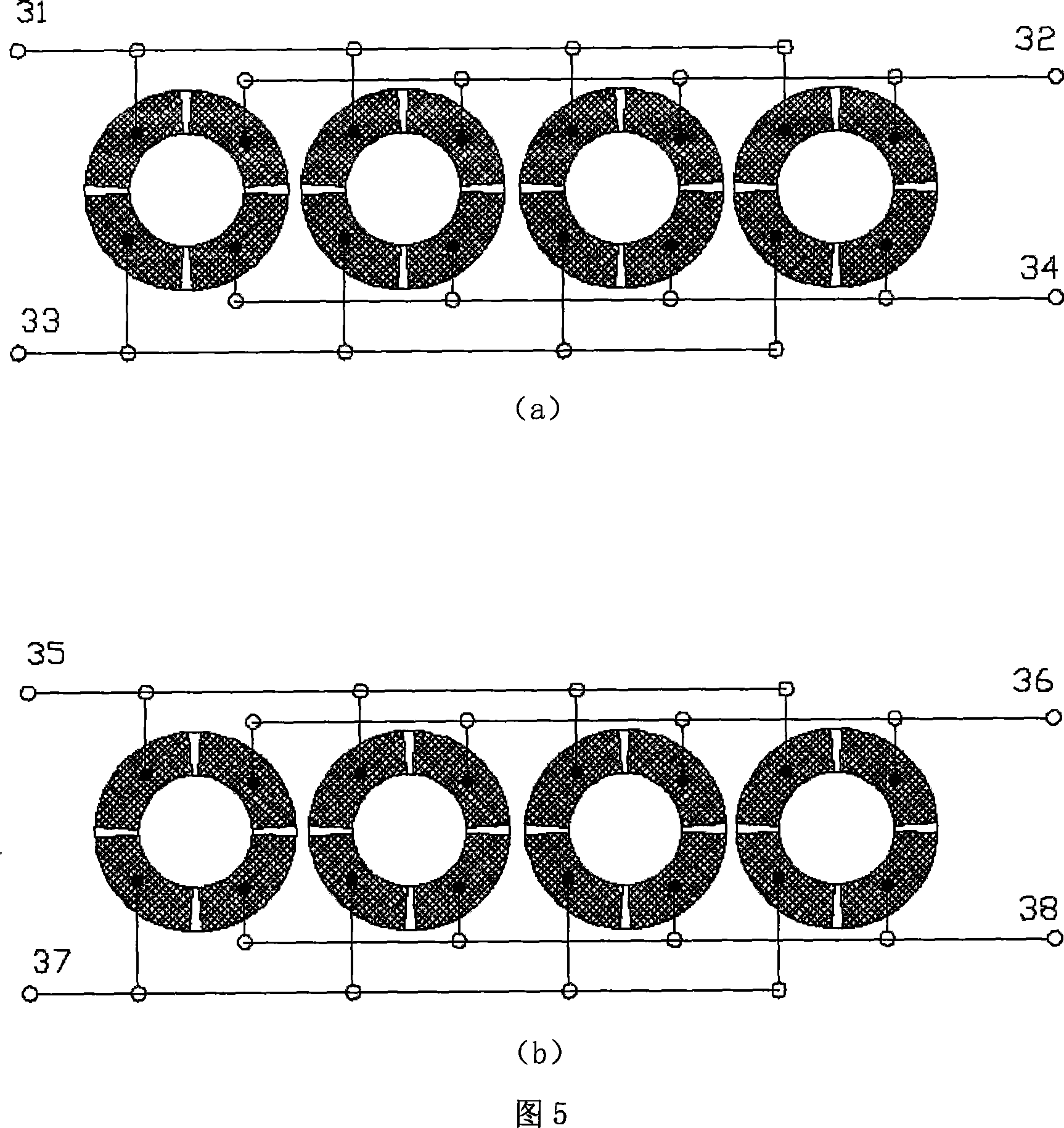

[0022] As shown in FIG. 1 , FIG. 2 and FIG. 3 , the cylindrical double-wheel foot-driven linear ultrasonic motor of the present invention is mainly composed of a stator assembly, a mover assembly and a bracket. The stator assembly is a completely symmetrical structure. The stator assembly consists of four sets of identical piezoelectric ceramics 2, 4, 5, 7 and two supports 3, 6, two pressure blocks 18, 19 and two nuts 20, 21 and It consists of a stepped cylinder 1; on the left side of the stator assembly, the first group of piezoelectric ceramics 4 is clamped between the stepped cylinder 1 and the support 3, and the second group of piezoelectric ceramics 2 is clamped between the support 3 and the pressure Between the blocks 18, the nuts 20 fix the two groups of piezoelectric ceramics 2, 4, the support 3 and the pressing block 18 in the axial direction; each group of piezoelectric ceramics is composed of two identical piezoelectric ceramic rings, and each piezoelectric ceramic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com