Building-block railway and highway and submarine tunnel

A subsea tunnel and building block technology, applied in roads, tracks, roads, etc., can solve the problems of long construction period and high excavation cost, and achieve the effect of reducing construction difficulty, saving construction cost and shortening construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

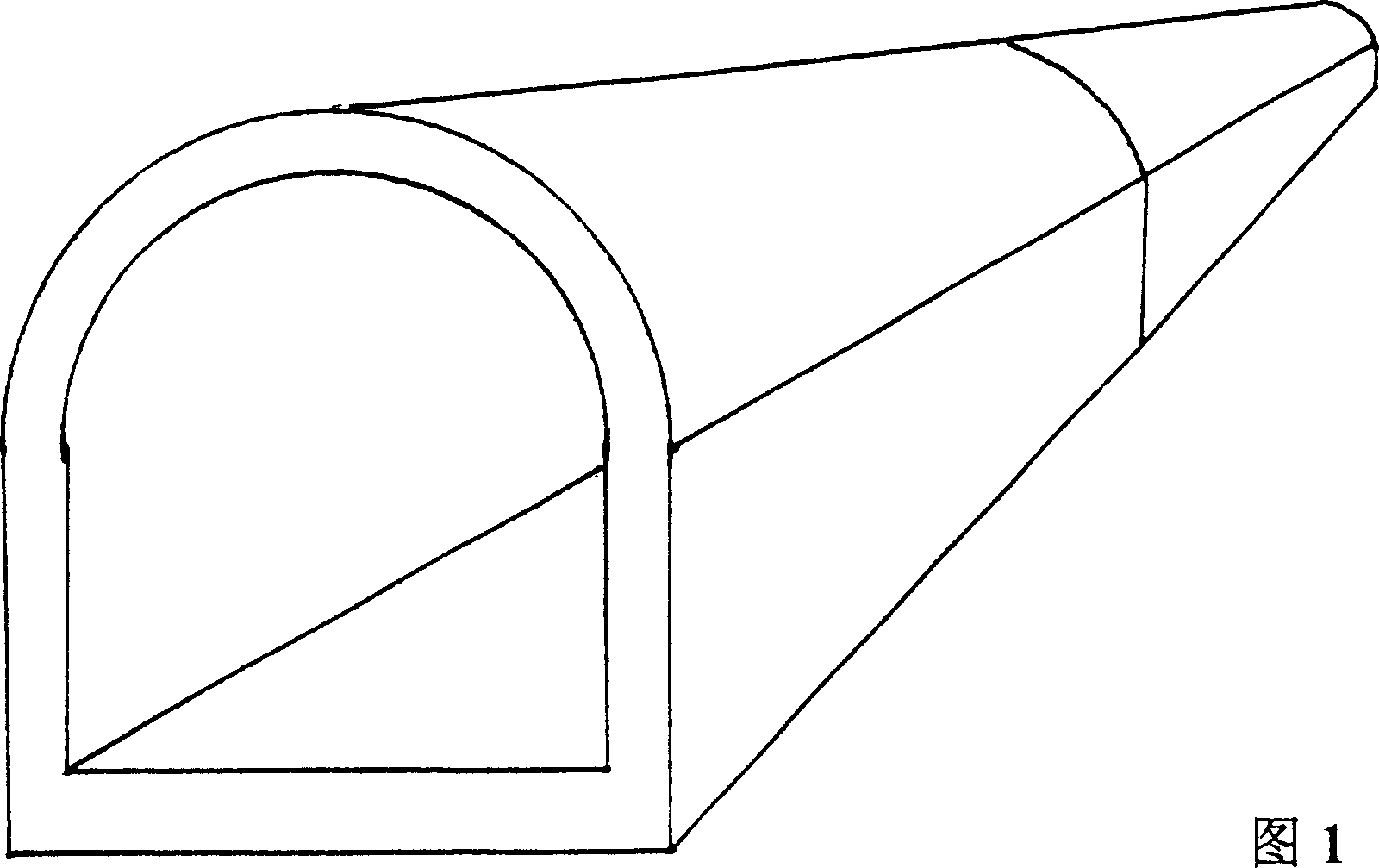

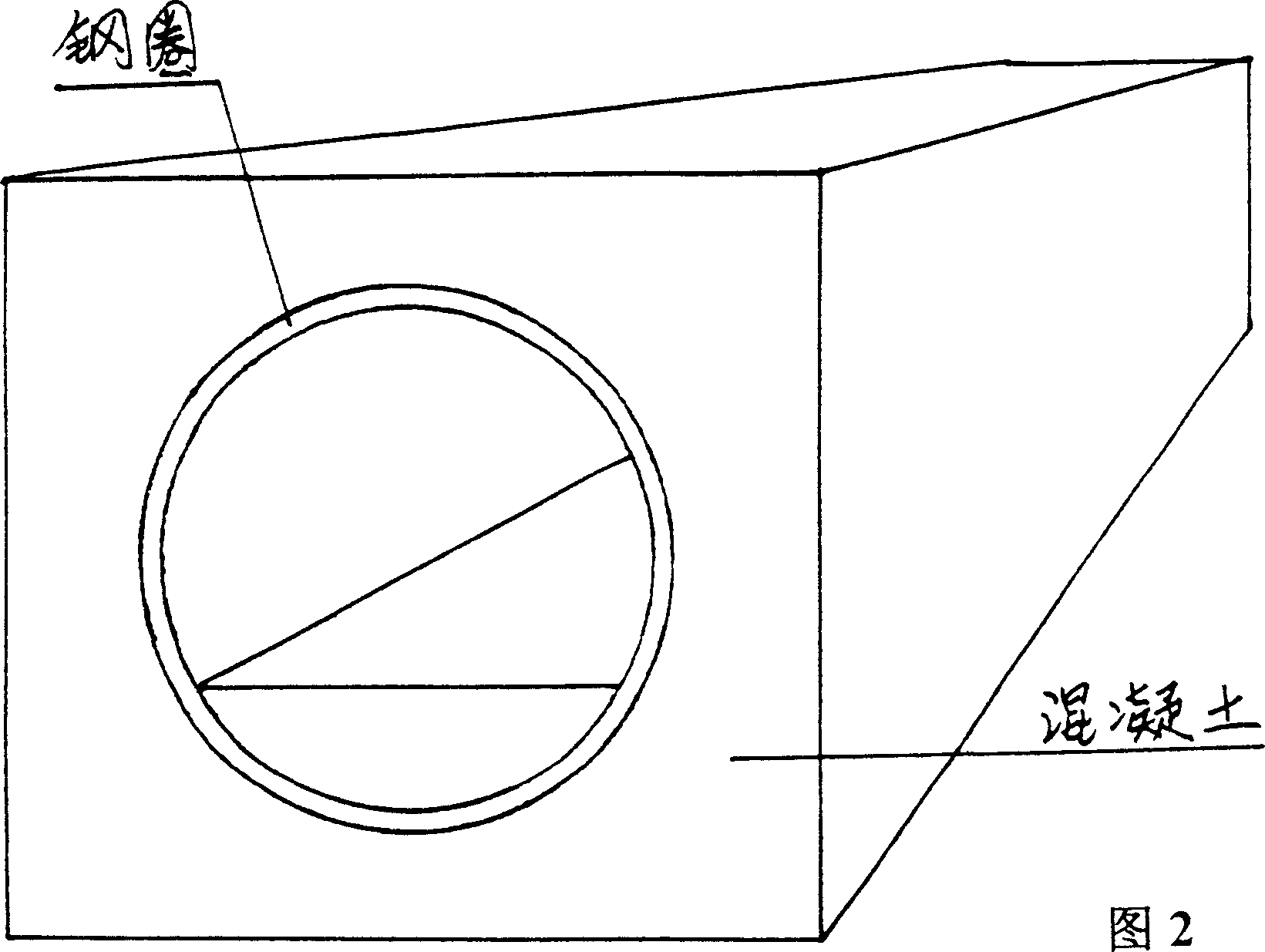

[0012] After designing the circuit, firstly deal with the foundation, then arrange the prefabricated building blocks and do a good job of connection. Railroads or roads can be repaired. The construction principle of the subsea tunnel is the same.

[0013] Building blocks can be prefabricated at the construction site, or they can be prefabricated in a factory and shipped to the construction site. For the construction of desert railways and roads, on-site prefabrication is ideal. If steel prefabricated parts are used, it is very convenient. The prefabricated parts are transported from the factory to the construction site, and they can be placed and connected.

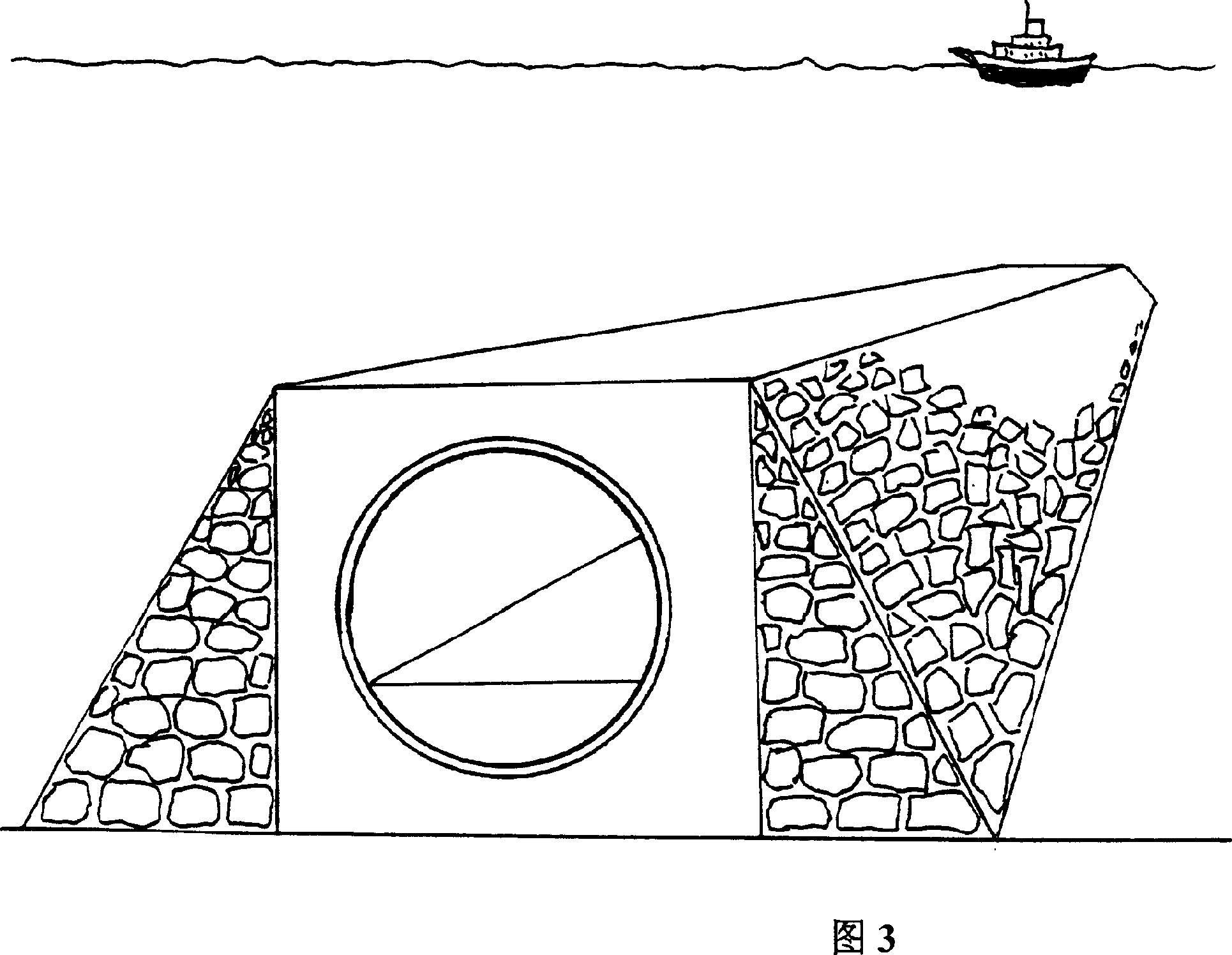

[0014] The construction of the subsea tunnel requires prefabricating building blocks in the nearest factory, transporting them to the construction site, and then placing and connecting them. Prepare the seabed foundation before placing it. All the work is carried out under the normal pressure of seawater. Welding or g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com