Fabric thrashing machine

A technology of dispersing machine and fiber, applied in cleaning machinery, carpet cleaning, floor cleaning, etc., can solve the problems of time-consuming, low efficiency and labor, and achieve the effect of solving low efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

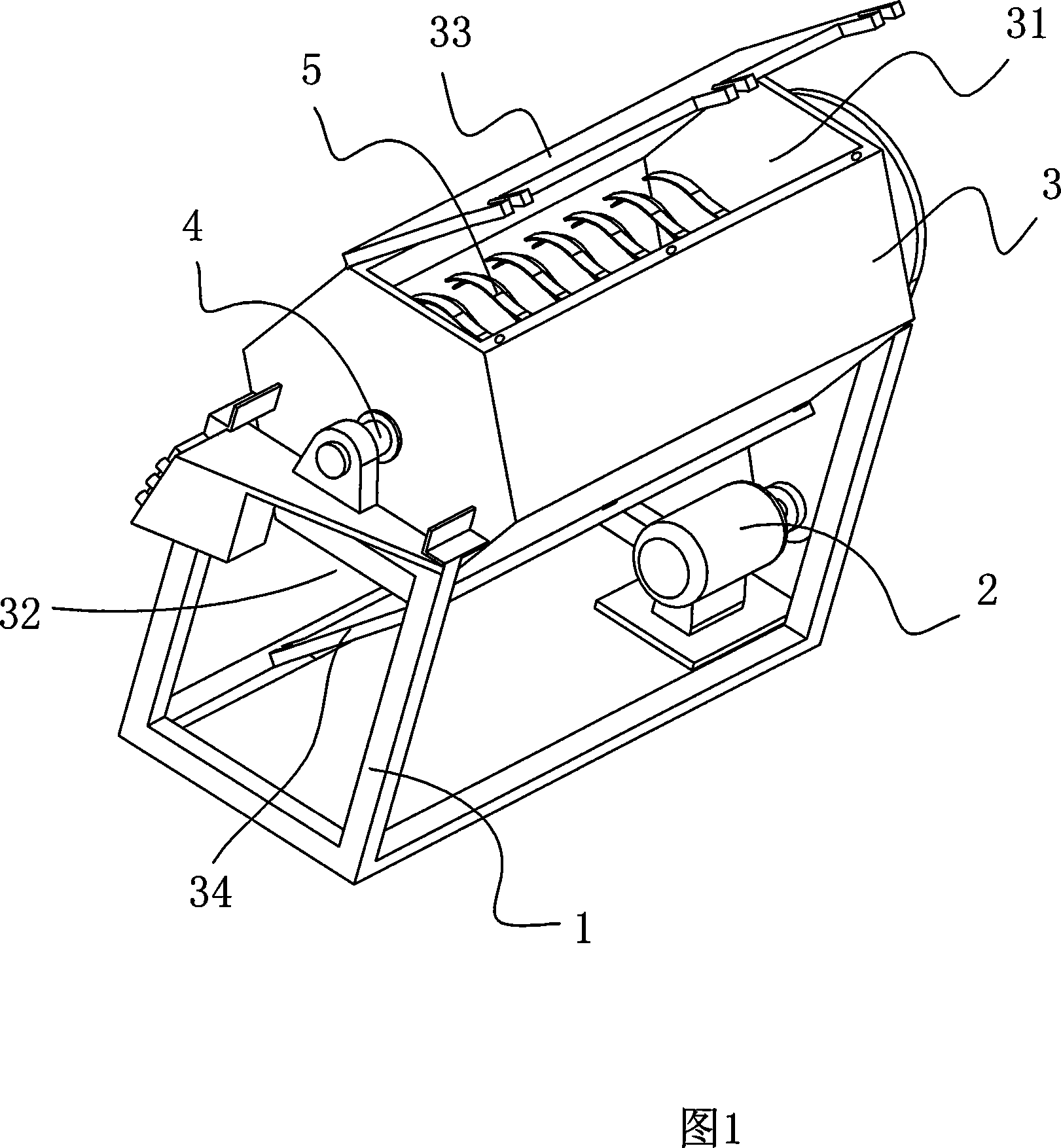

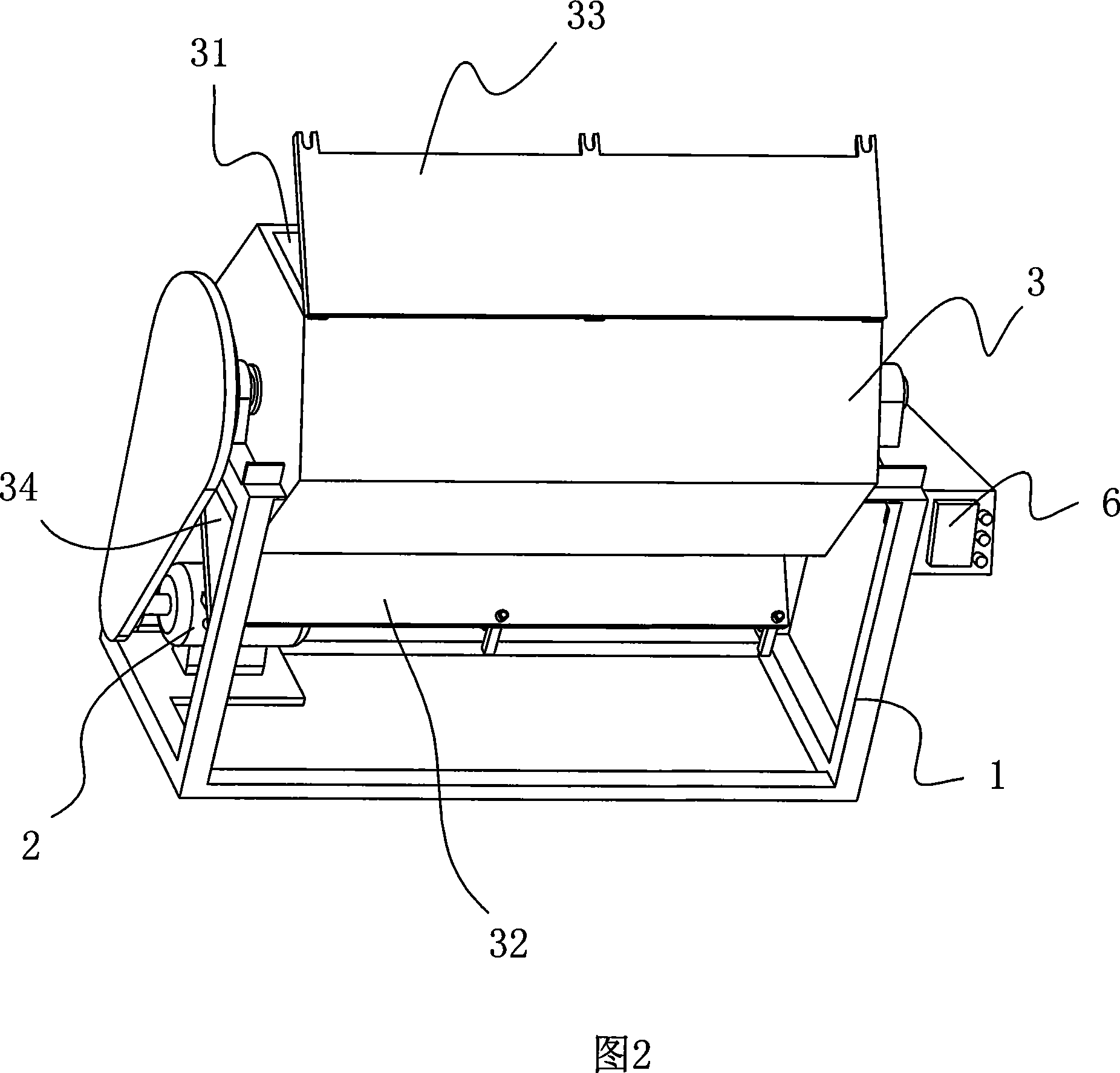

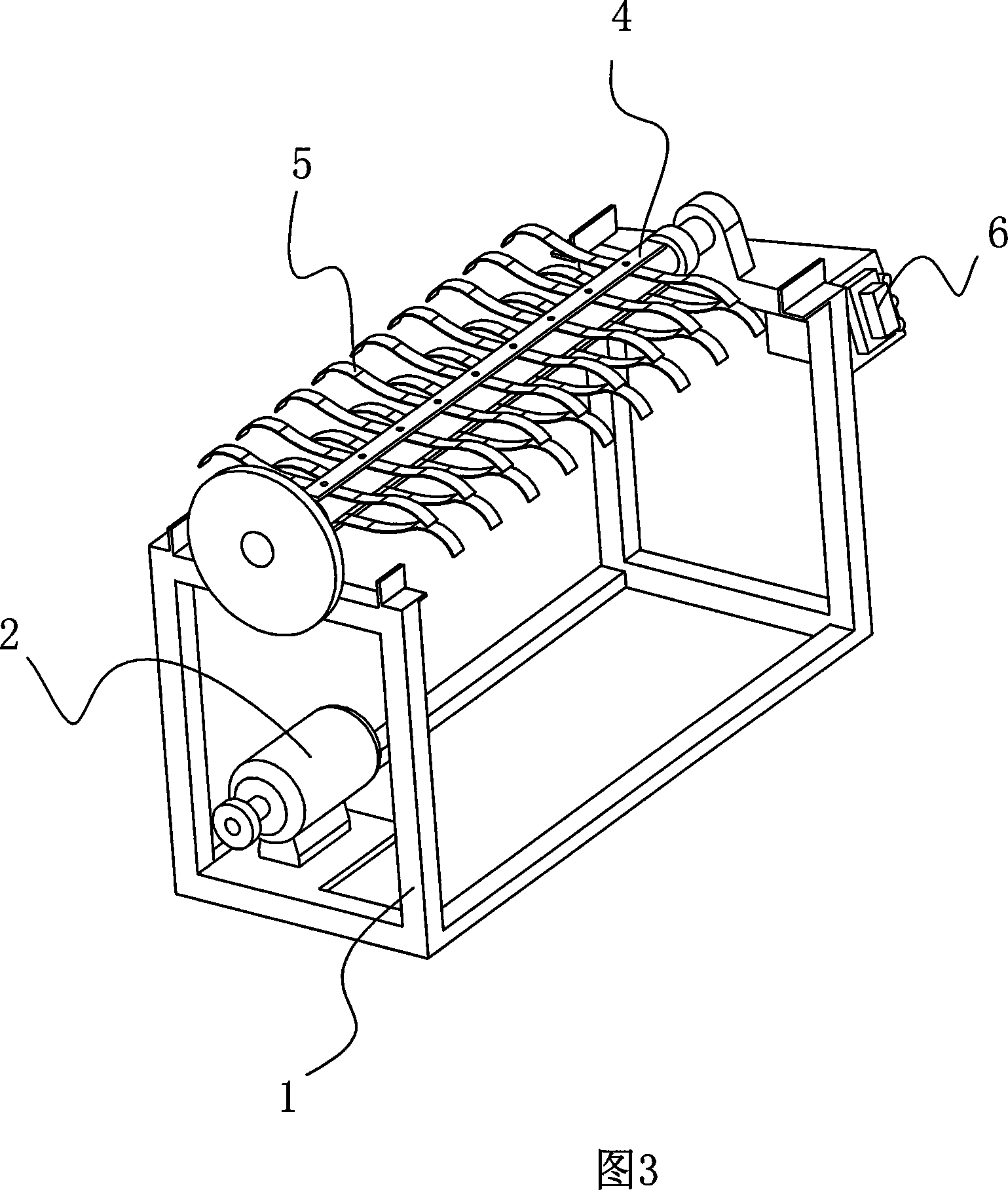

[0017] As shown in Figures 1-4, the fiber breaker of the present invention mainly includes a frame 1, a motor 2, a control device 6, a casing 3, a main shaft 4 and a loose action member 5, wherein the casing 3 has a hexagonal shape Barrel shape, horizontally arranged on the frame 1. An inlet 31 for putting in processed products and an outlet 32 for taking out finished products are respectively provided on the upper and lower parts of the casing 3, and there are cover plates 33, 34 that can be opened and locked at the inlets and outlets.

[0018] The main shaft 4 is located in the inside of the casing 3, wherein the two ends pass through the casing 3 and are installed on two support frames on the frame 1, and the motor 2 drives the main shaft to rotate forward or reversely through a belt and a pulley.

[0019] The control device 3 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com