Auxiliary discharging and circulating drying device for bio-organic fertilizer

A bio-organic fertilizer and auxiliary cutting technology, applied in the direction of bio-organic part treatment, drying, dryer, etc., can solve the problem of uneven drying of the central part, to improve efficiency, improve drying efficiency, and improve whereabouts speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

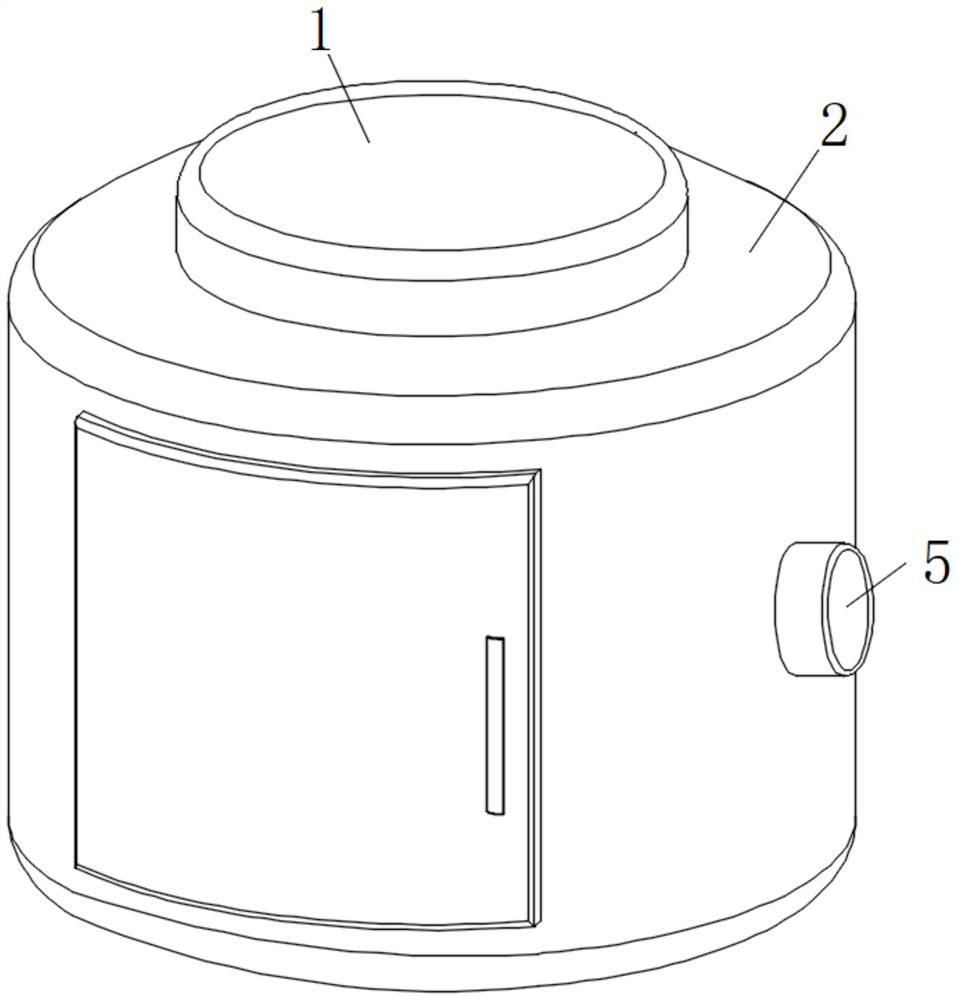

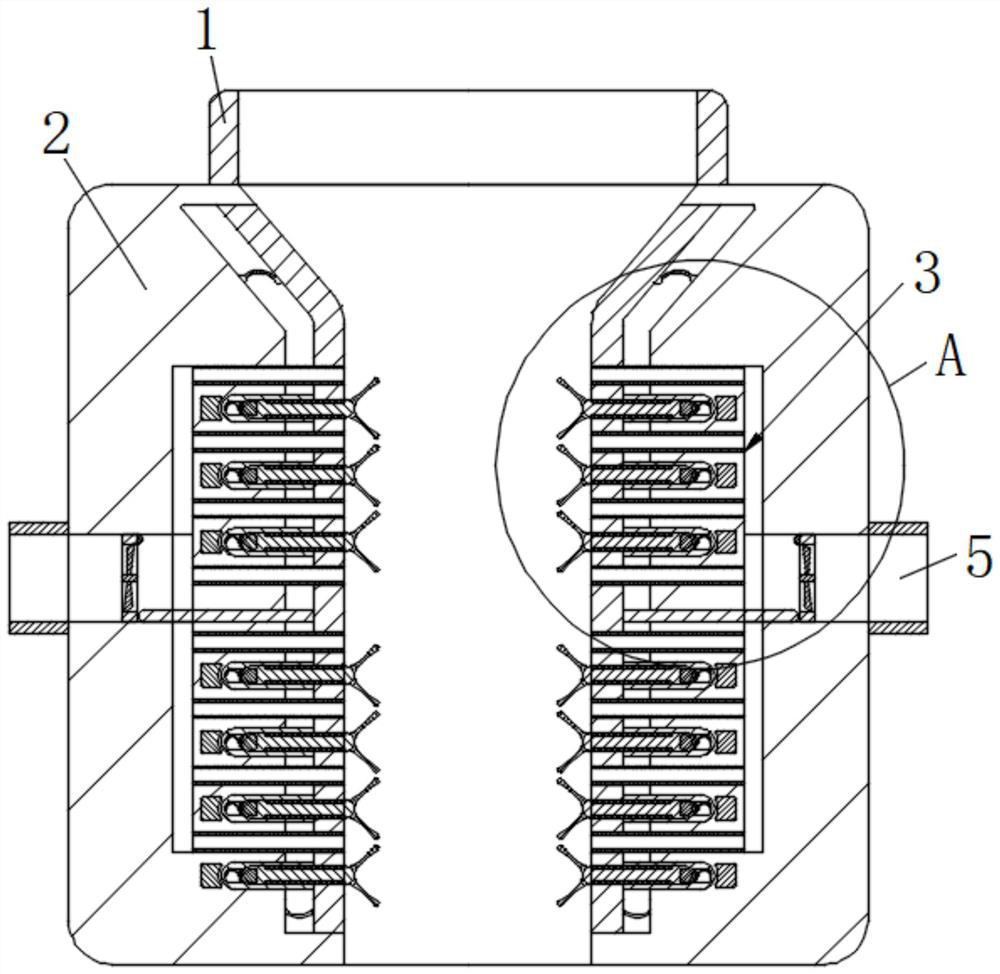

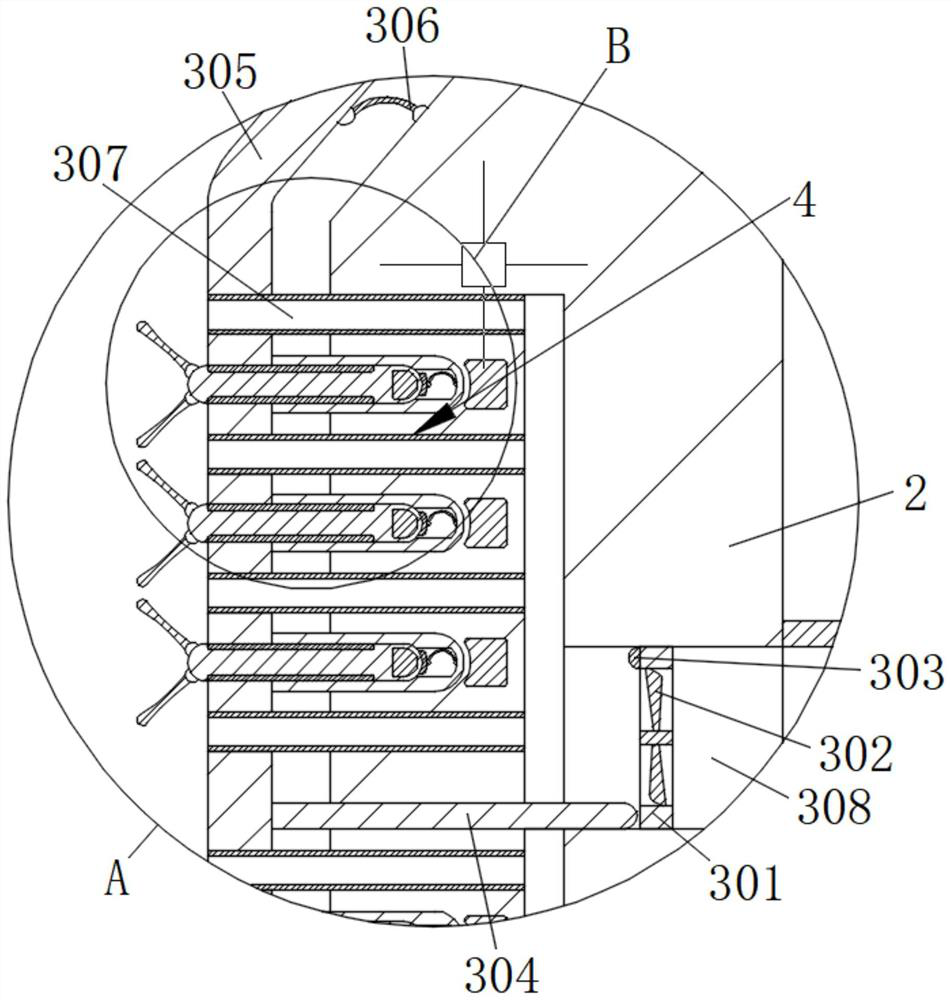

[0023] see Figure 1-4 , the present invention provides a technical solution: an auxiliary cutting and circulating drying device for biological organic fertilizer, comprising a box body 2, an outlet is opened at the bottom of the box body 2, a box door is hinged on the front of the box body 2, and the top of the box body 2 is fixed The inlet pipe 1 is connected, and the two sides of the box body 2 are fixedly connected with a hot air pipe 5. The inside of the hot air pipe 5 is communicated with the interior of the hot air groove, the interior of the hot air groove is communicated with the interior of the air groove 308, and the interior of the air groove 308 is communicated with the interior of the sliding pipe 307. , a vibration drying mechanism 3 is arranged inside the box body 2;

[0024] The vibration drying mechanism 3 includes a turntable 301, a fan 302, and a convex block 303. The side of the convex block 303 and the connecting rod 304 close to each other is an arc surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com