Anti-blocking filtering device for enzyme preparation production

A filter device and enzyme preparation technology, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of waste of manpower, water consumption, poor airtightness, etc., and achieve improved anti-blocking effect, efficient, stable and clean Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

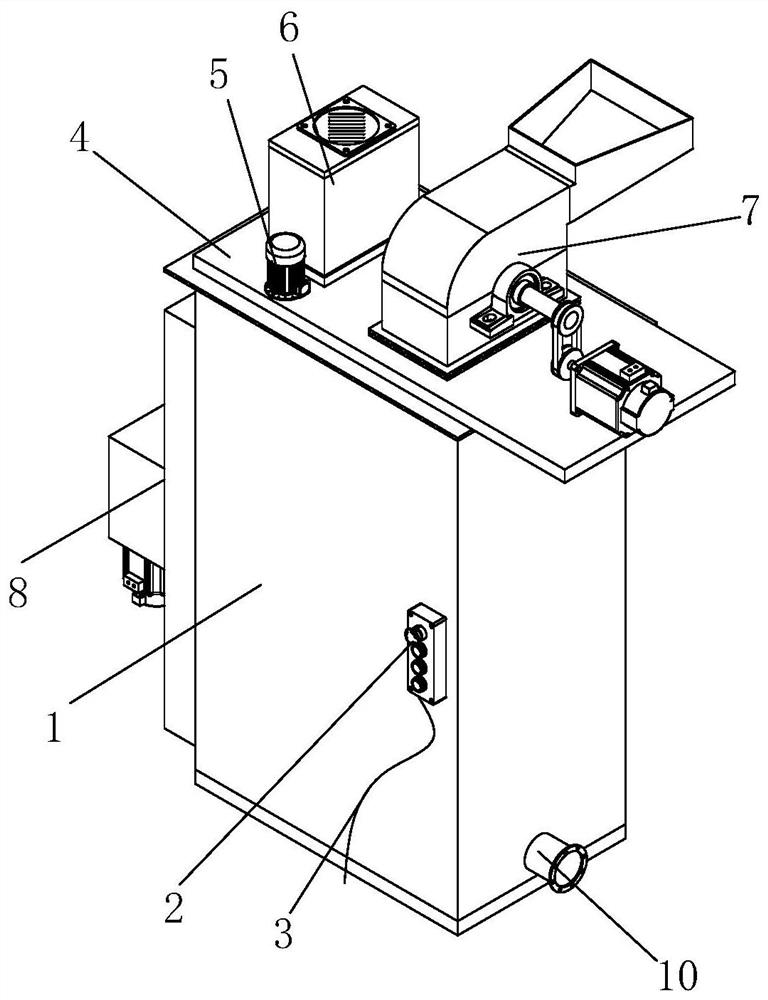

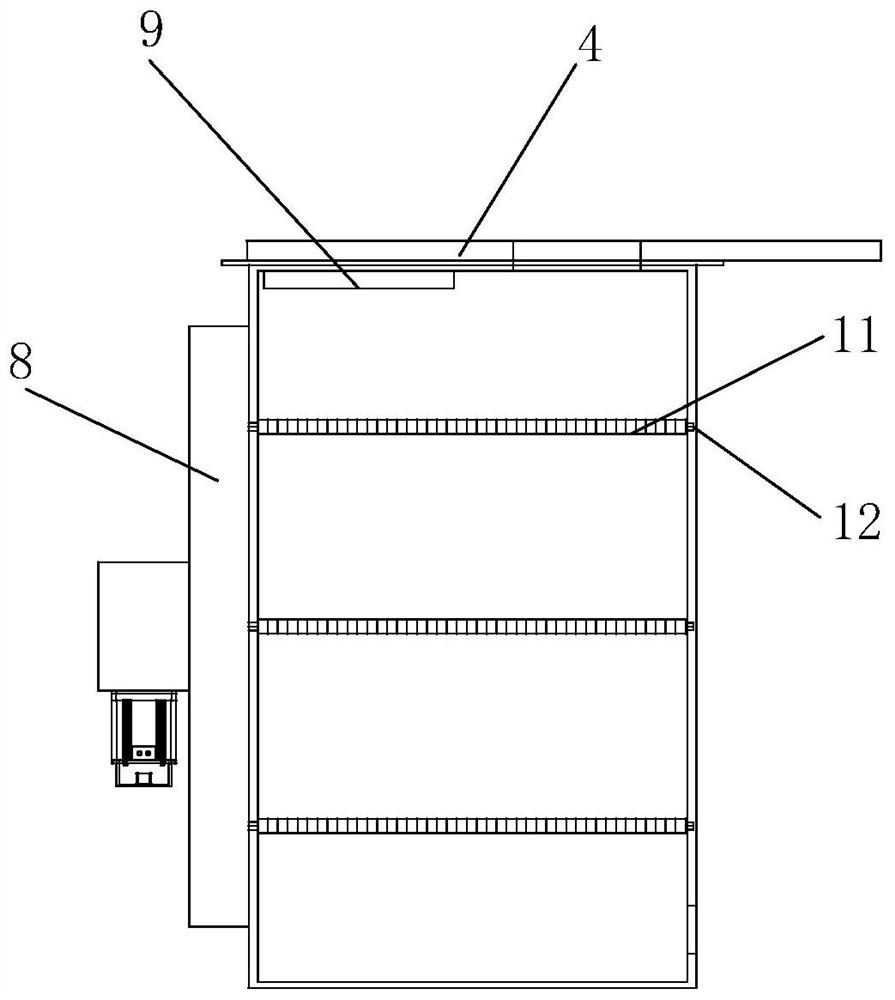

[0033] see figure 1 and figure 2 , the present invention provides an anti-clogging filter device for enzyme preparation production through improvement, including a box body 1, a controller 2 is installed at the right end of the front surface of the box body 1, a power cord 3 is arranged at the bottom of the controller 2, and the box body 1 The top plate 4 is fixed on the top, the first motor 5 is installed on the left front end of the top plate 4, the main body 6 of the purification device is fixed on the left end of the top plate 4, and the discharge pipe 10 is installed on the lower right side of the main body 6 of the purification device. A filter screen 11 is installed, and a layer of silica gel layer is bonded to the position where the four ends of the filter screen 11 meet the inner side of the box body 1, and the thickness of the silica gel layer is 2cm. During the rotation of the three sets of filter screens 11, the minimum distance between them is 5cm, and the sealin...

Embodiment 2

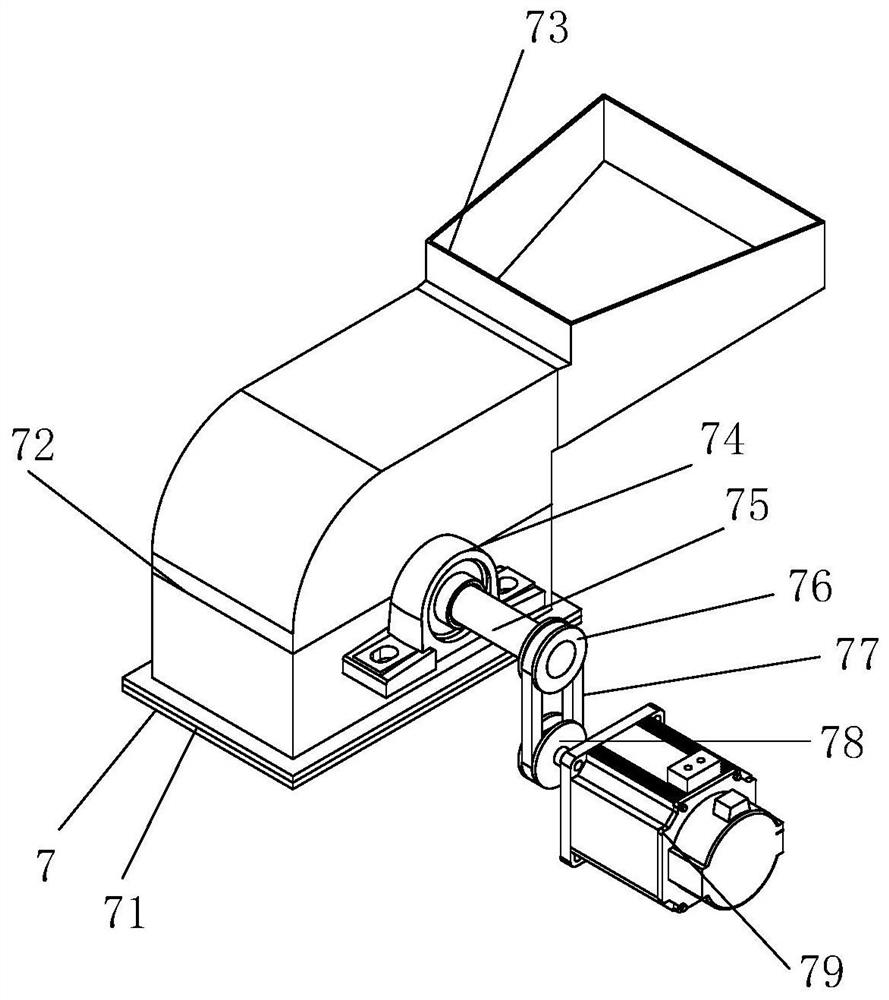

[0040] The present invention provides a kind of anti-clogging filtering device that is used for the production of enzyme preparation through improving here, and the bottom of feeding hopper 73 is inclined shape, and the inner wall of feeding hopper 73 is smooth shape, convenient feeding, easy to clean; An arc-shaped groove is opened between the four-end bar-shaped grooves 8341, and the position of the arc-shaped groove matches the top rear end of the rotating part 832 to realize stable guidance during transmission; the outside of the embedded groove 936 is open, and the inner diameter of the embedded groove 936 The size is larger than the inner side of the connecting rod 933, which is convenient for the connecting rod 933 to enter the embedded groove 936; the side of the sealing part 934 is bonded with a rubber layer with a thickness of 1 cm, which effectively realizes airtightness and good sealing; the inner side of the inner ring 937 is inverted Angled to allow condensation t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com