Water leaching table for steel pipe, petroleum well pipe and drill pipe medium frequency heat treatment system

A heat treatment system and oil well pipe technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems affecting the service life of induction heating coils and heating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

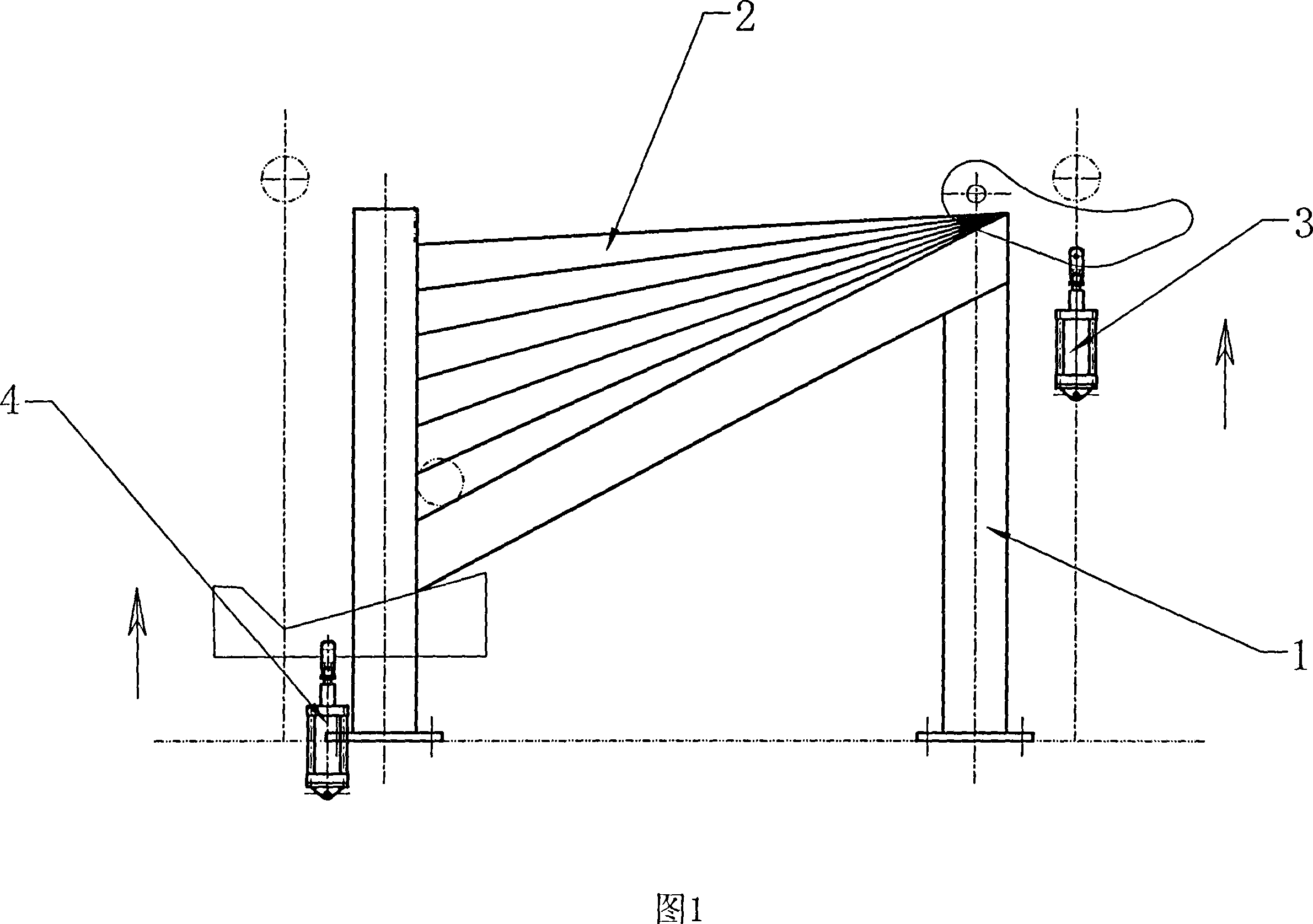

[0008] Referring to the accompanying drawings, its structure is composed of several guide rails 2, each guide rail 2 is arranged non-parallel to the guide rails 2, and the drain table 1 is inclined in two directions, one of which is the drain table 1 and the workpiece steel pipe or oil. The axes of oil well pipes or drill pipes are inclined at 2-5 degrees, and the other direction is that the axis direction of the guide rails 2 forming the drainage table 1 is inclined at 0-20 degrees, and each guide rail 2 has an angle of intersecting each other.

[0009] The intersection angle between each guide rail 2 is 2-20 degrees.

[0010] The workpiece steel pipe or oil well pipe or drill pipe can be automatically shifted, and the workpiece steel pipe or oil well pipe and drill pipe can be automatically arranged downward in sequence. When the workpiece steel pipe, oil well pipe or drill pipe is automatically shifted, the workpiece steel pipe or oil The water in the oil well pipe or drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com