Injection mold with water blowing mechanism

An injection mold and water blowing technology, which is applied in the field of injection molds with a water blowing mechanism, can solve problems such as reducing the service life of the mold and corrosion of the mold, and achieve the effects of prolonging the service life, avoiding corrosion, and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

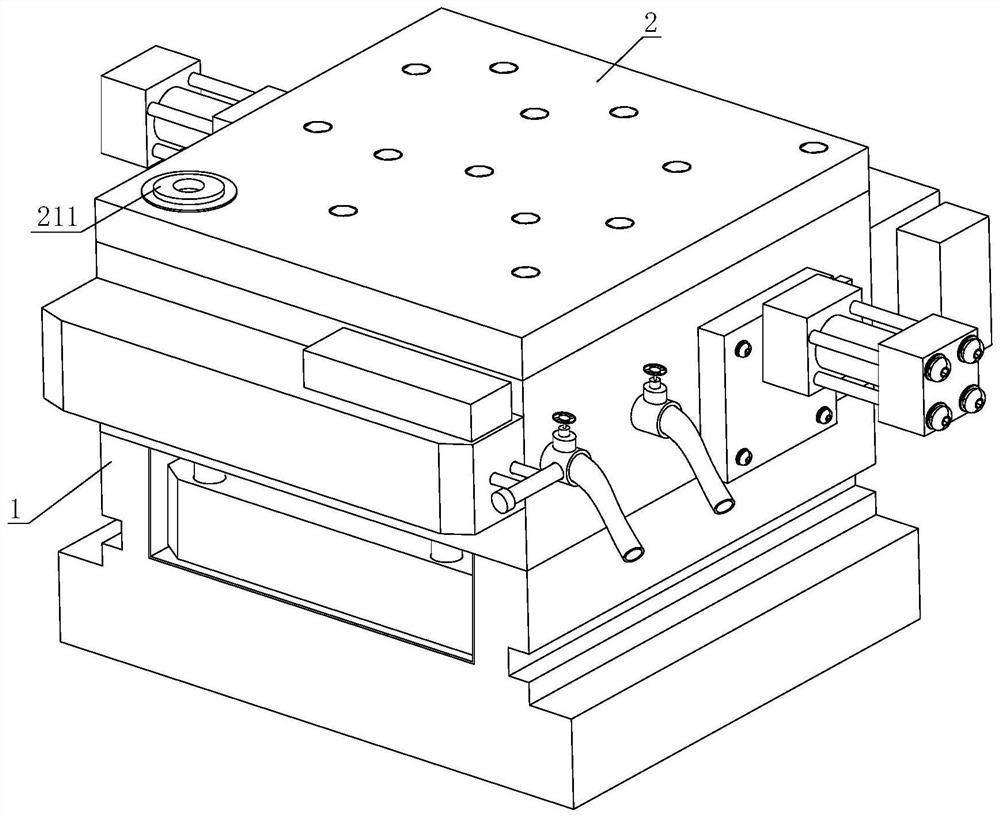

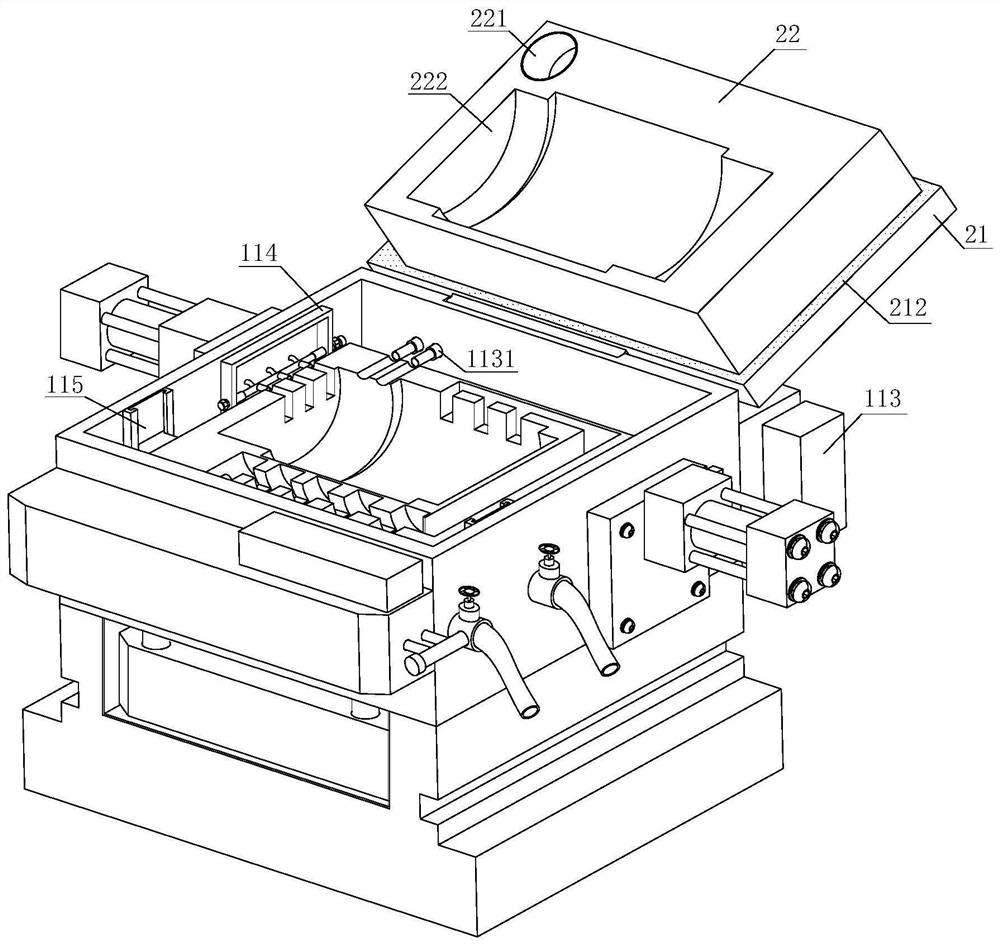

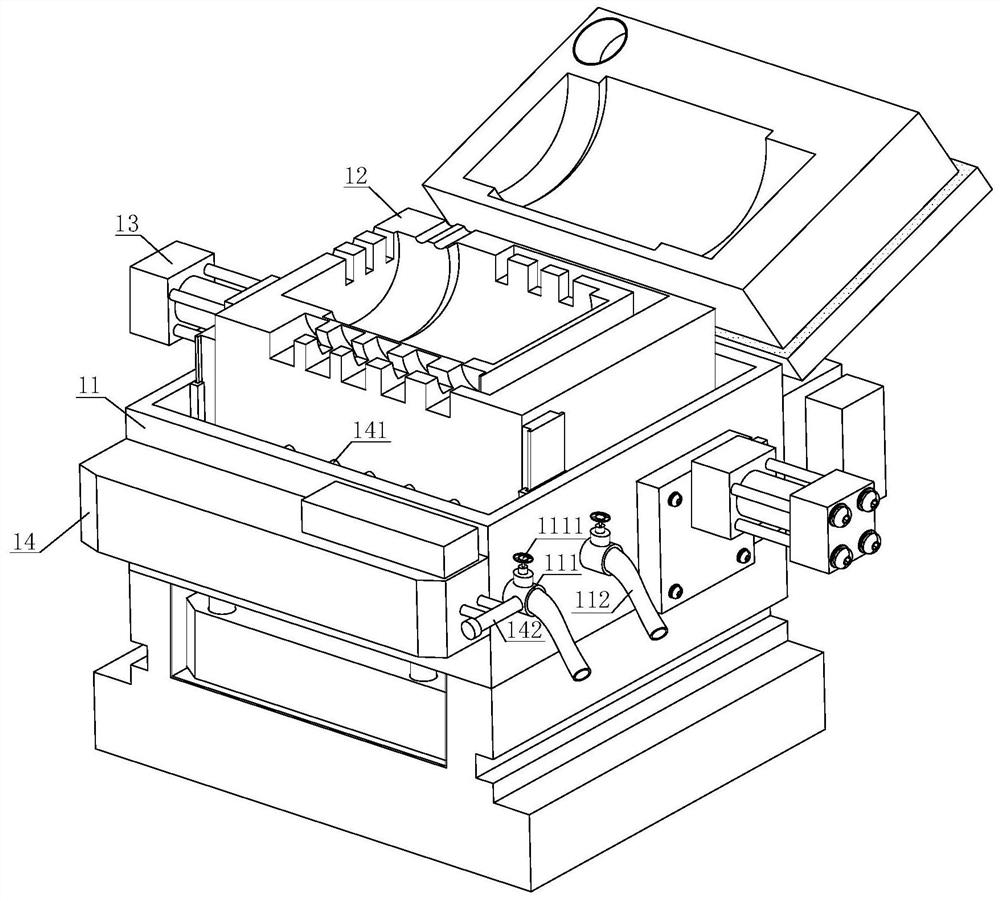

[0030] refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 7 , an injection mold with a water blowing mechanism, comprising an injection molding mechanism 1 and an upper cover mechanism 2, one side of the injection molding mechanism 1 is movably connected to the upper cover mechanism 2, and the injection molding mechanism 1 includes a housing 11, a lower mold Structure 12, air pump 13 and suction filter pump 14, the lower mold structure 12 is installed in the inner cavity of the housing 11, and an air pump 13 is arranged on one side of the outer wall of the housing 11, and the housing 11 is far away from the air pump 13 A cooling water inlet pipe 111 and a cooling water outlet pipe 112 are respectively installed on one side of the outer wall, the cooling water inlet pipe 111 and the cooling water outlet pipe 112 are connected to the inner cavity of the housing 11 and a valve 1111 is arranged at the upper end of the housing 11. The rear end is fixed with a slu...

Embodiment 2

[0032] refer to figure 2 , an injection mold with a water blowing mechanism, the upper cover mechanism 2 includes a cover body 21 and an upper mold body 22, the surface of the cover body 21 is provided with a cold air input port 211 near the corner, and the inner panel edge of the cover body 21 is provided There is a sealing strip 212, and the inner side of the cover body 21 is also fixed with an upper mold body 22; the surface of the upper mold body 22 is processed with a through hole 221 corresponding to the cold air input port 211, and the through hole 221 communicates with the cold air input port 211, and The surface of the upper mold body 22 is also processed with an upper molding cavity 222, which can use the cold air input port 211 to deliver cold air to the molding cavity during water-cooling molding, thereby further improving the molding rate.

Embodiment 3

[0034] refer to Figure 5-6 , an injection mold with a water blowing mechanism, the lower mold structure 12 includes a lower mold body 121 and a lower molding cavity 122, the surface of the lower mold body 121 is provided with a lower molding cavity 122, and the lower mold body 121 is close to the side of the blowing structure 114 The edge of the outer wall is processed with an air delivery groove 1211, one end of the air delivery groove 1211 is connected to the lower forming cavity 122 and the other end is connected to the air delivery pipe 1143; Groove 1221 and several sets of drainage grooves 1222, and the surface of the lower mold body 121 is also processed with a water groove 1212, one end of the water groove 1212 is connected to the drainage groove 1222; the side of the lower mold body 121 near the suction filter pump 14 is processed with several sets The water tank 1213 is connected by the water channel 12131 between adjacent water tanks 1213, and only one end of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com