Method for using adsorption natural gas as automobile fuel

A technology for adsorbing natural gas and natural gas, applied in gaseous engine fuel, fuel system, combustion engine, etc., can solve problems such as potential safety hazards, high compression ratio of natural gas, and loss of activity of super activated carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

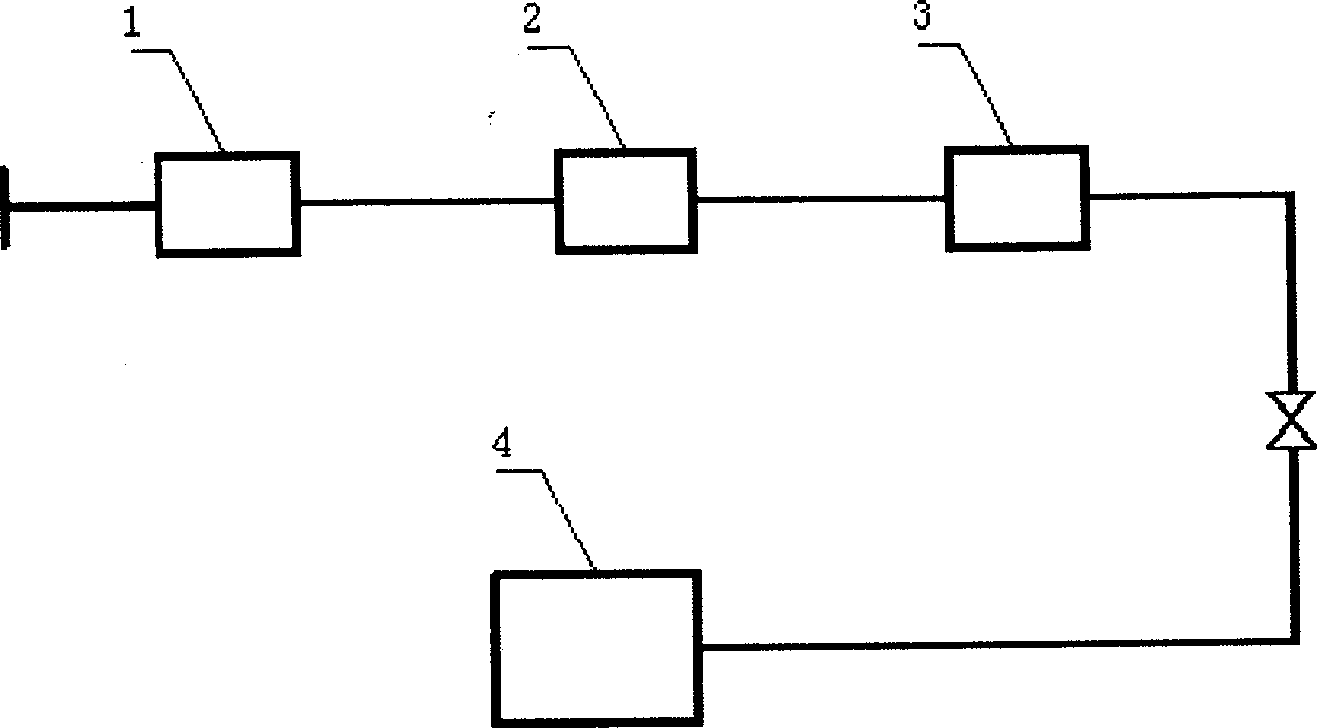

[0014] A method of using adsorbed natural gas as a vehicle fuel. The pre-hydrocarbon removal process is carried out at a gas filling station. The main equipment includes a dehydrogenation device equipped with silica gel products for automatic switching between work and regeneration 1, a high-pressure tank 2 for gas storage, and a car charging Natural gas dispenser 3; the heat exchange process is carried out on the car, the main equipment is the adsorption natural gas cylinder 4 with a heat exchanger, the circulating water inlet and outlet of the heat exchanger are connected with the automobile water tank through pipelines, and the adsorption natural gas cylinder adopts Made of 34Mn2V material, the external dimensions are 273×3.5×900, the design pressure is 7.5MPa, and the size of the center tube of the sleeve-and-tube heat exchanger is 57; The machine inflates the adsorbed natural gas cylinder. When the high-pressure natural gas is decompressed and inflated, the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com