Method for recovering aromatic hydrocarbons from hydrocarbons mixture with high content of aromatic hydrocarbons

A technology of hydrocarbon mixture and high aromatic hydrocarbons, applied in distillation purification/separation, azeotropic/extractive distillation, etc., can solve the problems of inability to overcome the limitation of aromatic hydrocarbon content, inability to handle raw materials, etc., to save equipment investment and operating costs, reduce The effect of equipment investment and improved operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

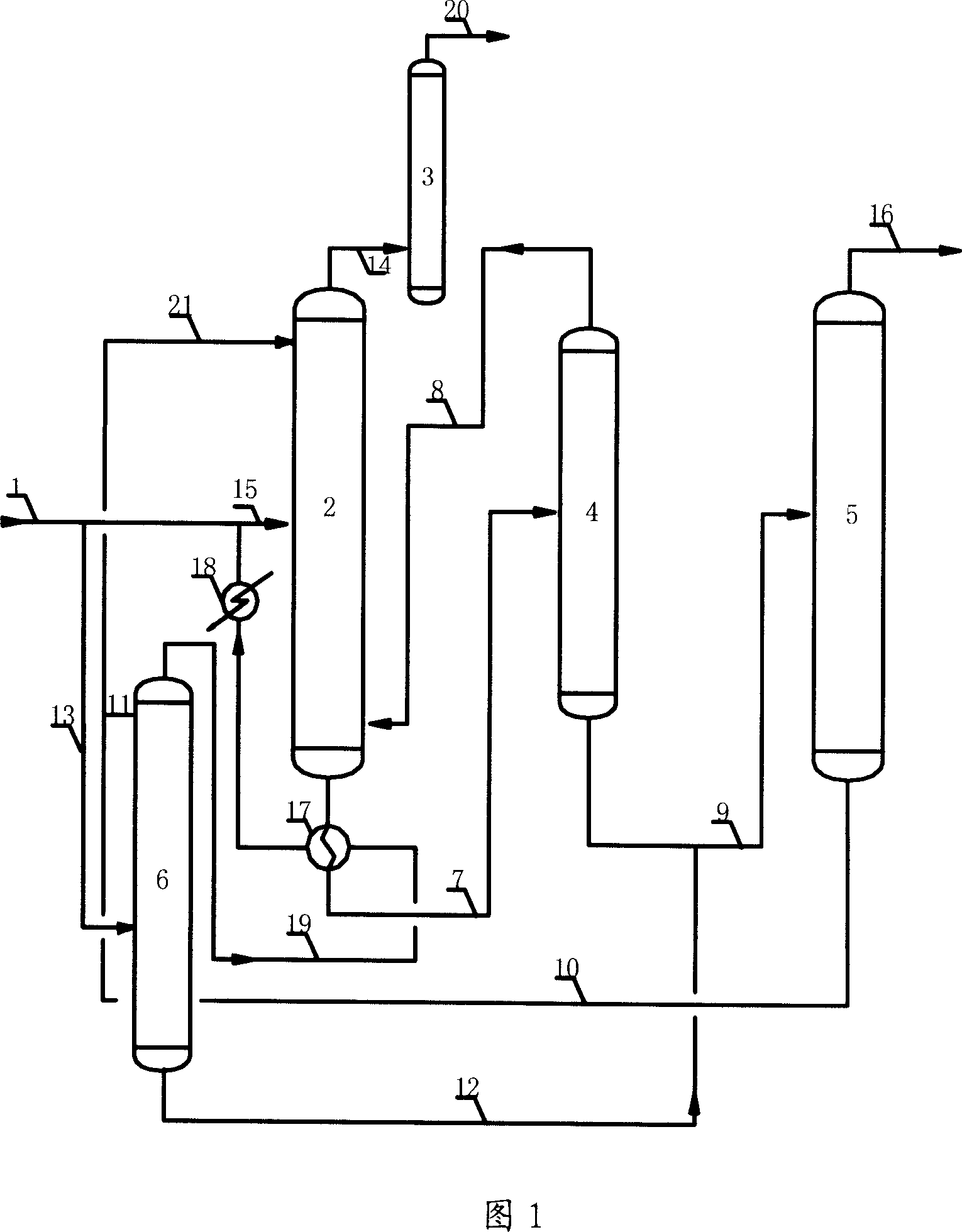

[0034] The process flow is shown in Figure 1. The raw material is the C6-C7 hydrocarbon mixture obtained after the pyrolysis hydrogenated gasoline is processed by the pre-fractionator. The aromatic content is 87%, and the flow rate is 37500kg / h. It is divided into two shares according to the weight ratio of 73.3:26.7 Hydrocarbon stream, wherein the first stream of hydrocarbon stream is introduced into the extraction distillation tower, and the second stream of hydrocarbon stream is introduced into the liquid-liquid extraction tower. Sulfolane is used as the aromatic hydrocarbon selective solvent, which contains a small amount of water. The raw material composition is shown in Table 1. The operating conditions of each tower See Table 2, and see Table 3 for the quality of recycled products and the total energy consumption of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com