Technique for producing window-open type broad safety line money paper by single-circle mesh paper machine

A rotary screen and paper machine technology, applied in paper machine, paper making, textile and paper making, etc., can solve the problems of difficult control of the upper and lower positions of the safety line, exposed lines of paper sheets, affecting product quality and yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

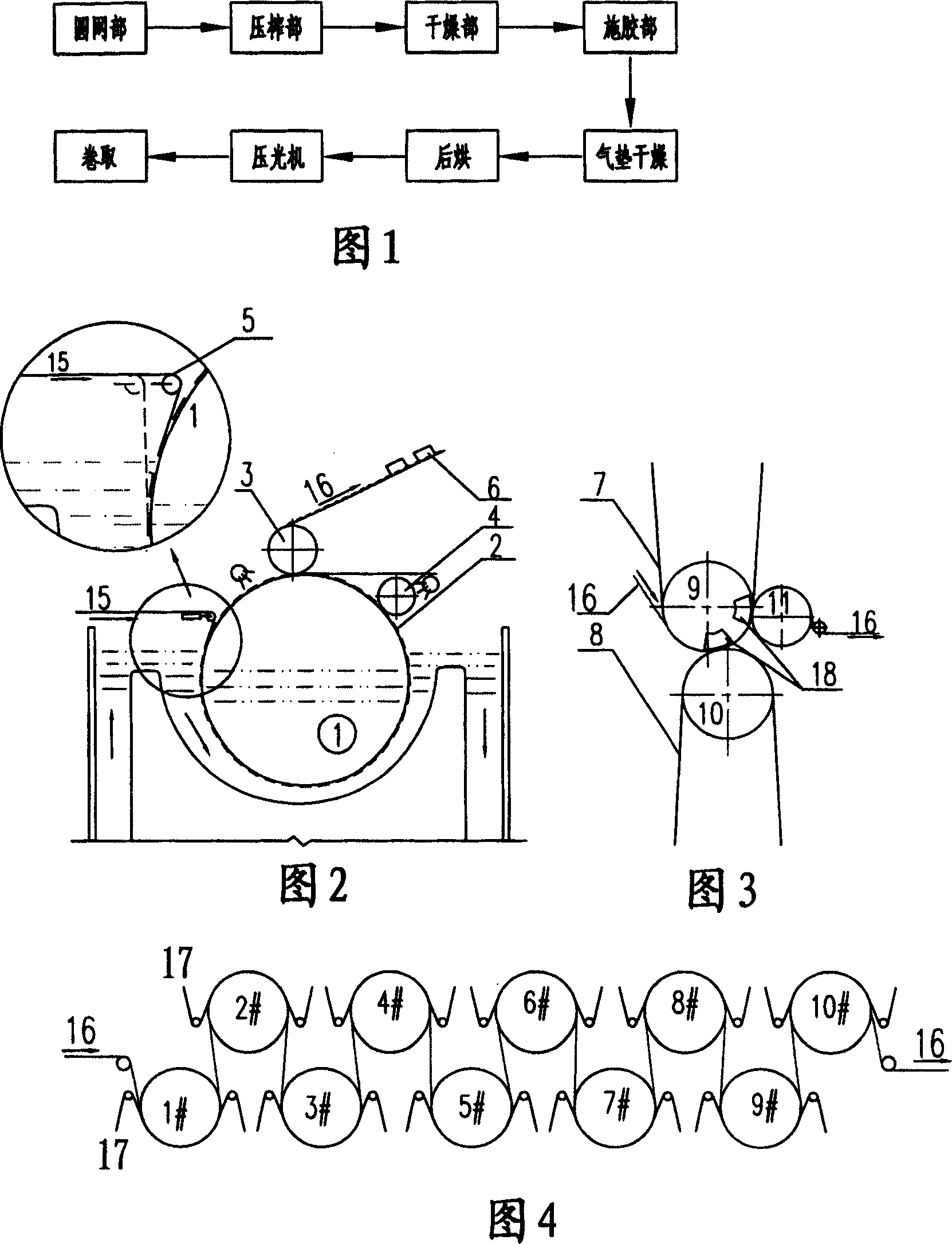

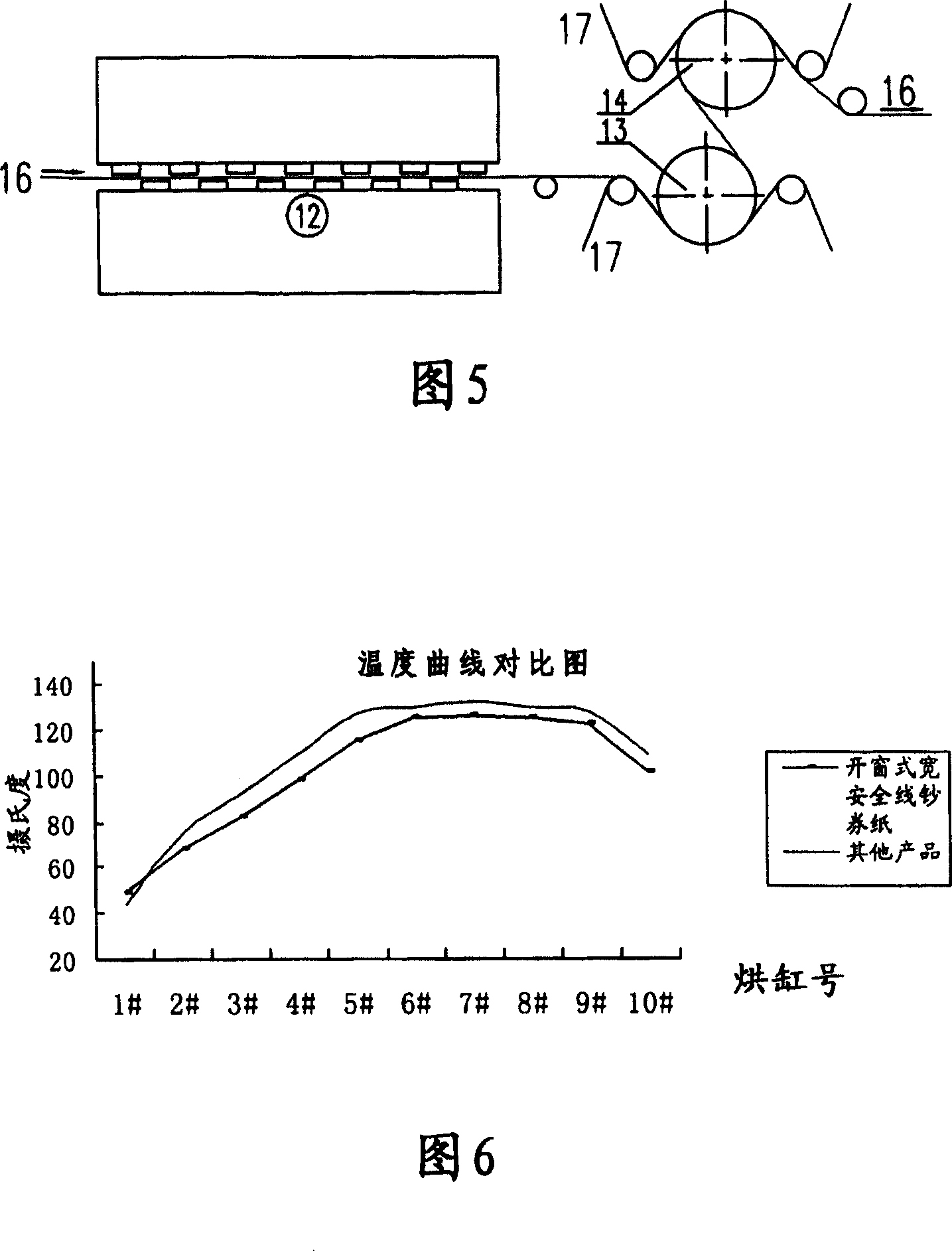

[0017] In the accompanying drawings, the number 1 shows the cylinder of the single cylinder paper machine, the number 2 shows the screen window plate, the number 3 shows the upper couch roll, and the number 4 shows the watermark roll , the label 5 shows the safety line release frame, the label 6 shows the vacuum box, the label 7 shows the upper felt, the label 8 shows the lower felt, the label 9 shows the vacuum press roller, and the label 10 shows the lower press roll, 11 shows the upper press roll, 12 shows the air cushion drying box, 13 shows the lower post-drying cylinder, and 14 shows the post-drying upper cylinder. The label 15 is a wide safety line, the label 16 is a paper sheet, the label 17 is a dry net, and the label 18 is a vacuum chamber.

[0018] The process of the present invention will be described with reference to the schematic flow diagram shown in FIG. 1 . The technical flow for producing the window-type wide security line banknote paper of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com