Variable displacement, constant (air density) compression ratio, constant air/fuel ratio and non air throttle reciprocating engine

A technology of air density and engine, applied in the direction of engine components, engine control, machine/engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

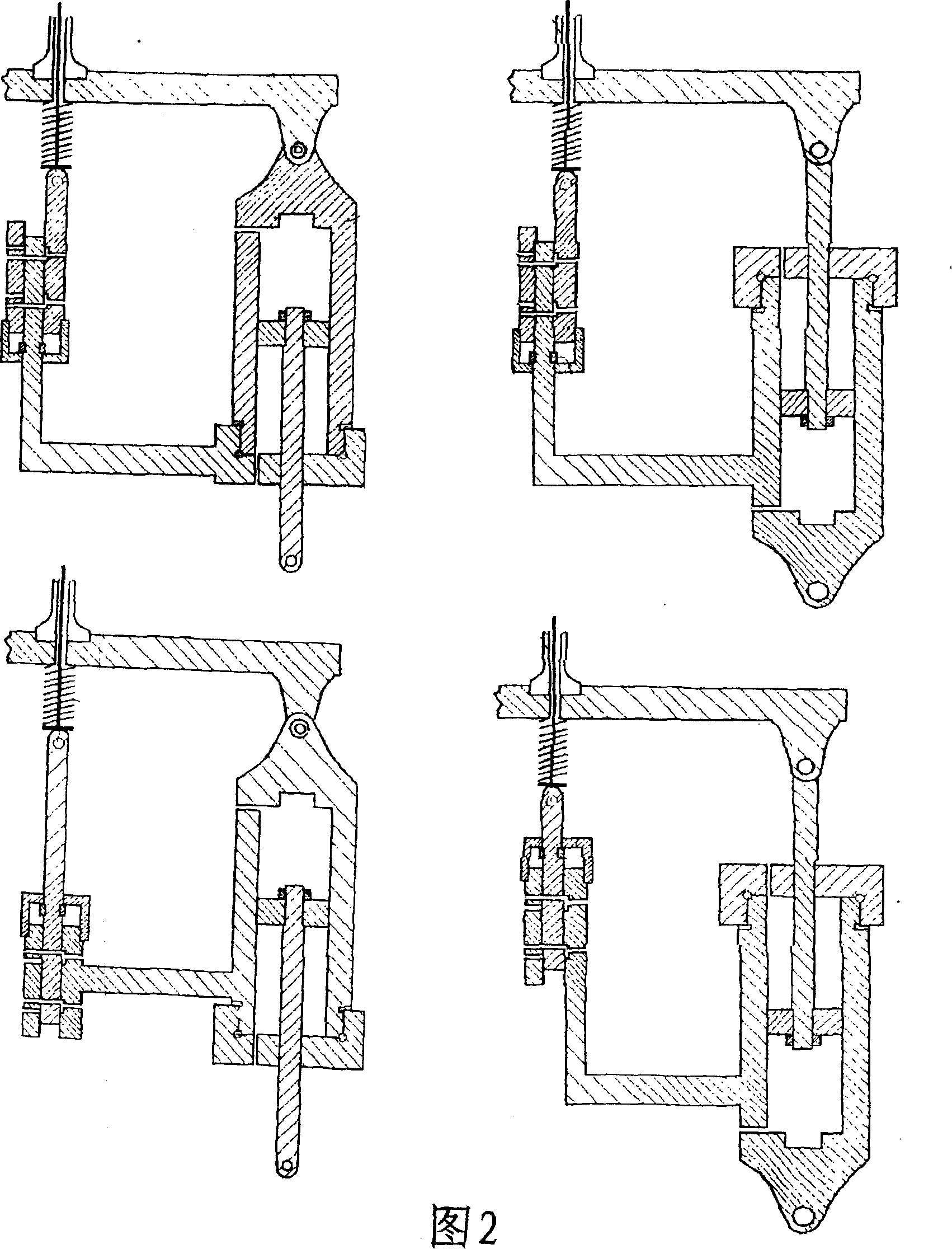

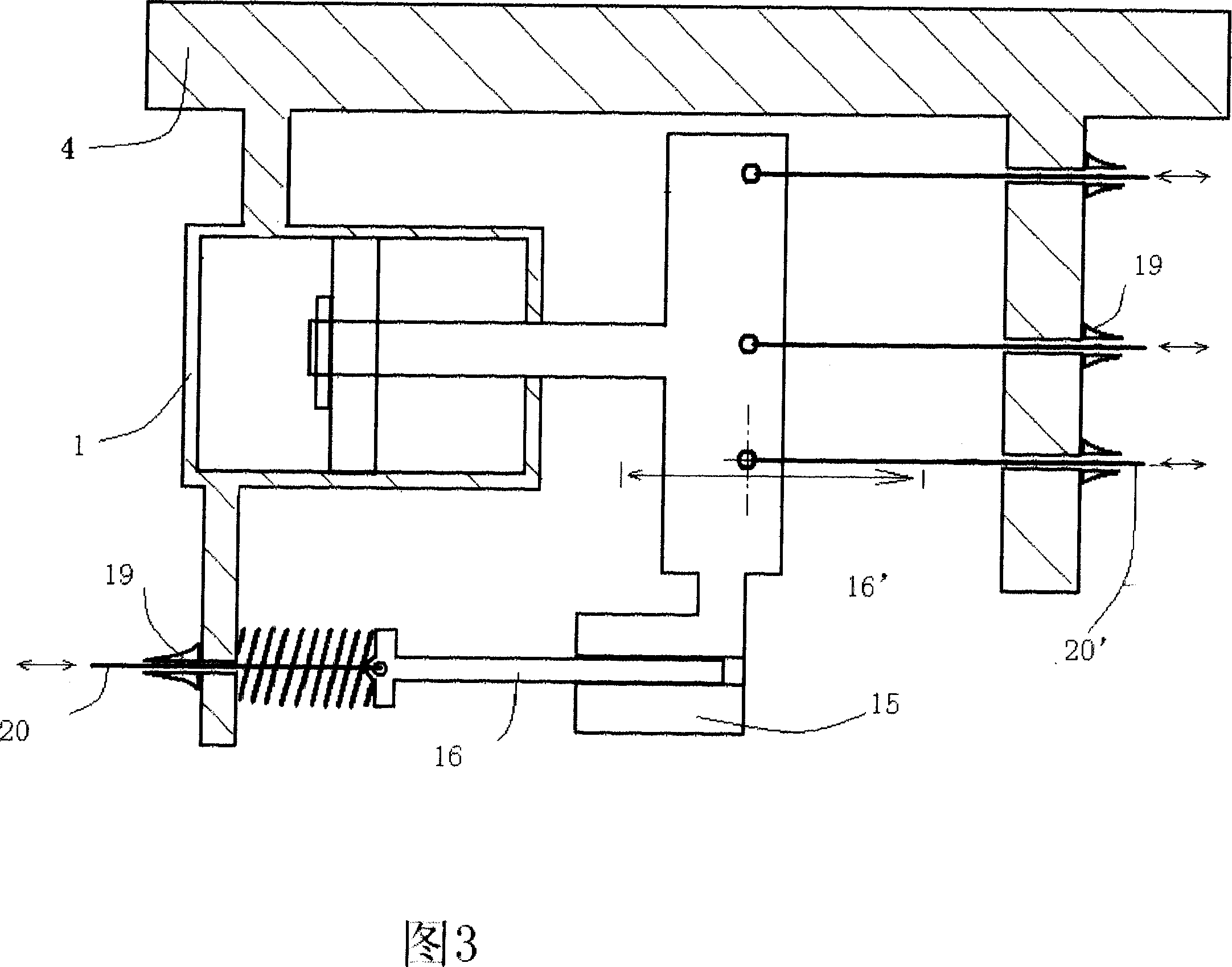

[0025] Simultaneously apply multiple synchronous linkage displacement devices and upper and lower cylinder moving devices on one engine. Linked combined camshaft mechanism, quasi-constant air-fuel ratio oil supply system.

[0026] Describe the specific embodiment of the present invention in detail with reference to accompanying drawing

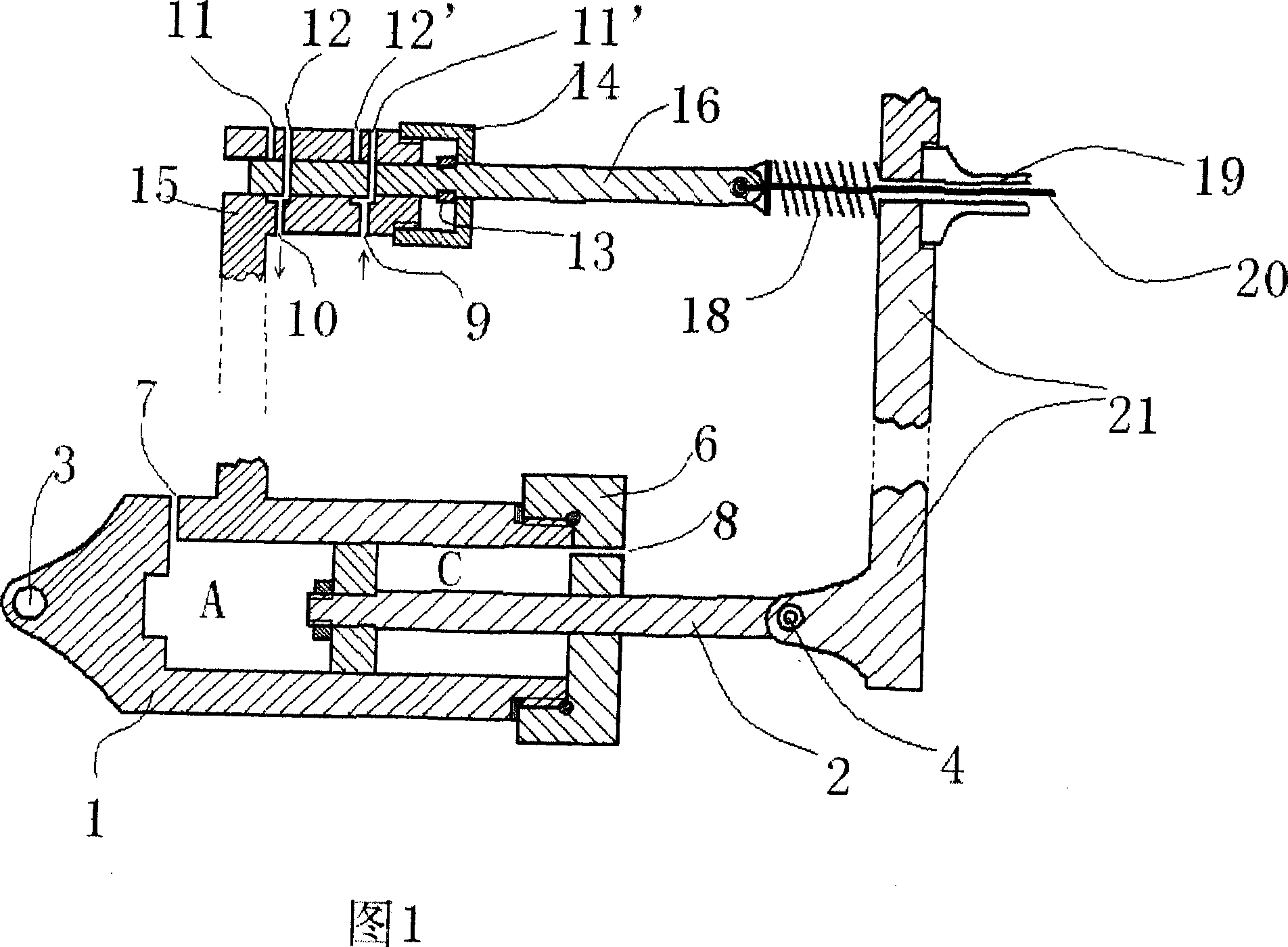

[0027] The preferred implementation of the displacement device is shown in Figure 1. The displacement device is to move the distance between the two parts of a certain system of the engine by manipulation. The follow-up reversing positioning valve is composed of a valve body 15, a plug rod 16, a limiting chamber 5, and a limiting snap ring 13.

[0028] The preferred embodiment of displacement device is as follows:

[0029] The valve body 15 of the following reversing positioning valve is rigidly connected with the cylinder body 1 of the oil cylinder and can move accordingly. The limit cavity 5 is a constant space between the end cover 14 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com