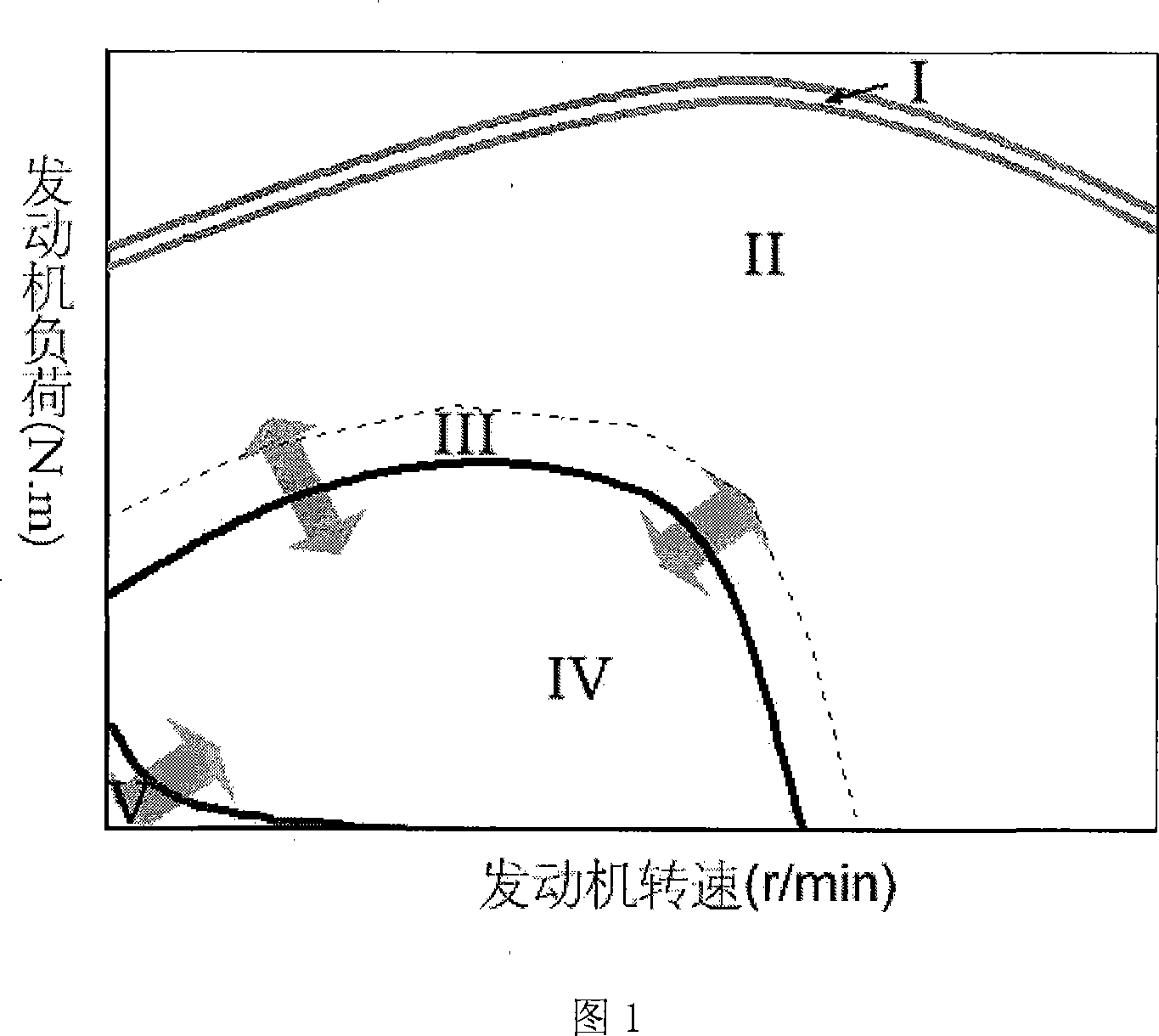

Full behavior air/fuel ratio control method of double mode directly jetting gasoline engine

A control method and technology of air-fuel ratio, applied in engine control, fuel injection control, electrical control and other directions, can solve rare problems, achieve the effect of avoiding interference, simplifying control strategy, avoiding knocking and misfire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] On a two-valve engine with a cylinder diameter of 95 mm, a compression ratio of 13, and a cone angle of 30°, the two-valve engine of the high-pressure swirl parachute gasoline electronic control injector has carried out normal operation in both modes and successfully switch between the two modes.

[0034] Experiments have proved that by adopting different air-fuel ratio strategies in different combustion modes, the respective advantages can be effectively brought into play. The theoretical air-fuel ratio is adopted in the ignition mode, and the three-way catalytic converter can be effectively used to reduce emissions, while the NOx emission in the compression ignition mode is very low, and the three-way catalytic converter can also be used to reduce HC and CO emissions, so that the after-treatment of the whole machine Device cost is effectively controlled. During the switching process, although there is a lean burn state in the ignition mode, because the time is very s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com