Electric hair drawing device

An electric and moving film technology, applied in clothing, hairdressing equipment, scorching hair roots, etc., can solve the problems of installation difficulty and high cost, increased energy consumption, noise level, vibration and discomfort of the hair puller, etc., to achieve no difficulty in manufacturing, The effect of improving hair removal efficiency and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

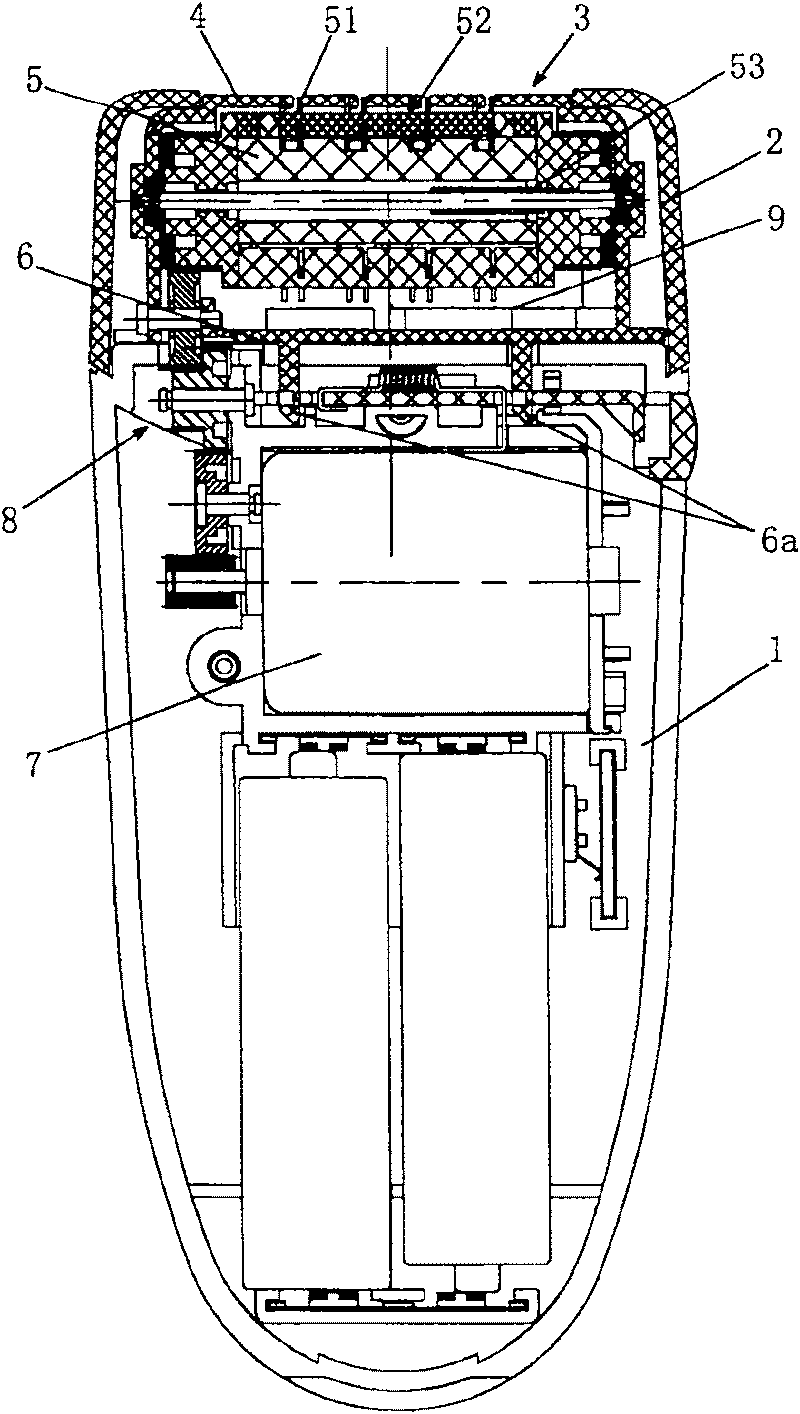

[0028] Such as figure 1 As shown, the electric hair puller includes a body 1 and a machine head 2 installed on the body 1 , and a driving motor 7 and a transmission gear transmission mechanism 8 are arranged in the body 1 .

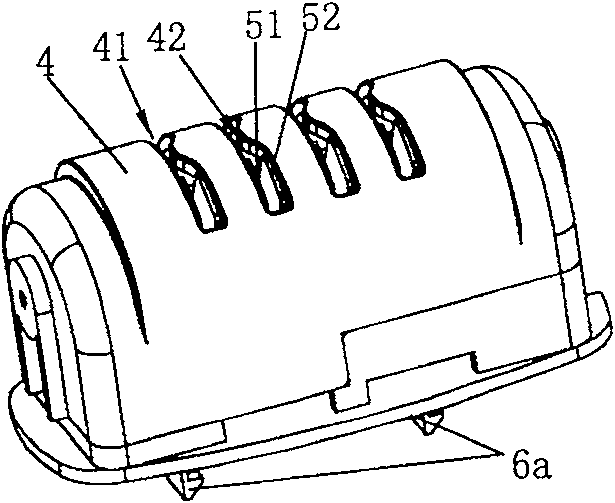

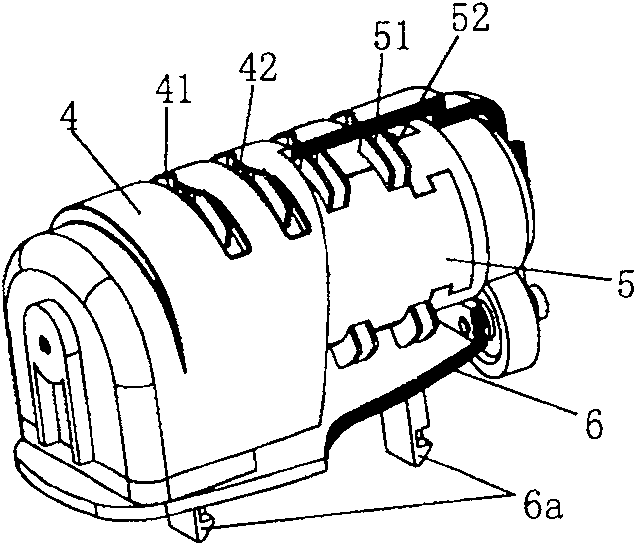

[0029] figure 1 The device on the head 2 of the electric hair puller shown has a Figure 2-5The hair-plucking assembly 3 described in detail in , the hair-plucking assembly 3 comprises a face mask 4 that contacts the skin during plucking, a hair-plucking head 5 and a base 6 that can be driven to rotate relative to the face cover, the face cover 4 and The base 6 encloses the accommodation chamber 9; the contour of the face mask 4 in contact with the skin is arc-shaped, and an arc-shaped groove 41 is formed on this position, and a smooth boss 42 is arranged on the edge of the arc-shaped groove 41; the hair-plucking head 5 Comprising a mandrel 57 and a rotary cylinder 58 that are assembled together and can only move in its axial direction, and a return s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com