Making method of C-type ironic core of voltage mutual inductor

A technology of voltage transformer and manufacturing method, which is applied in the direction of inductor/transformer/magnet manufacturing, transformer/inductor core, circuit, etc. Mass production, difficulty in mass production, etc., to ensure long-term safe operation, scientific and reasonable production process, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

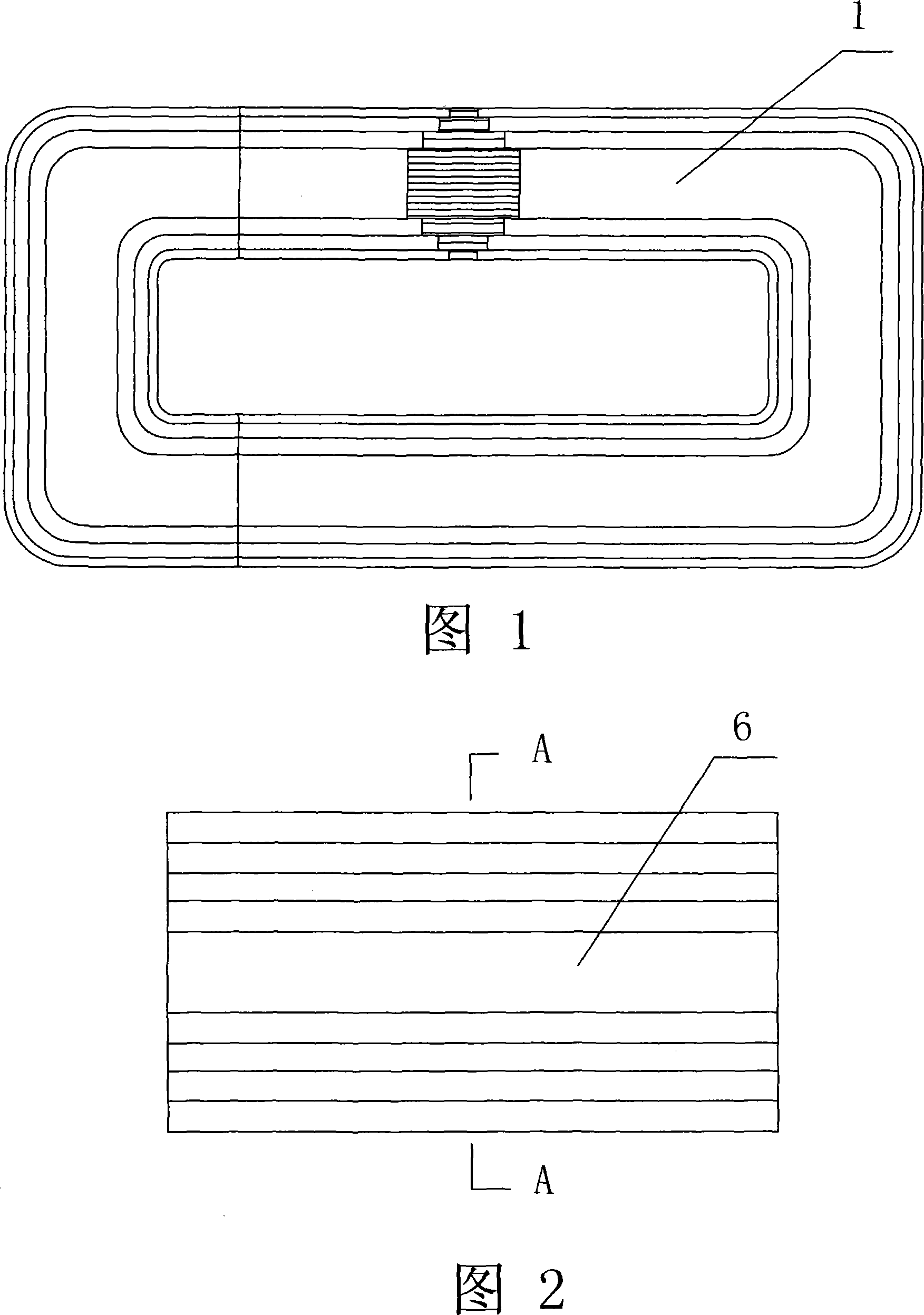

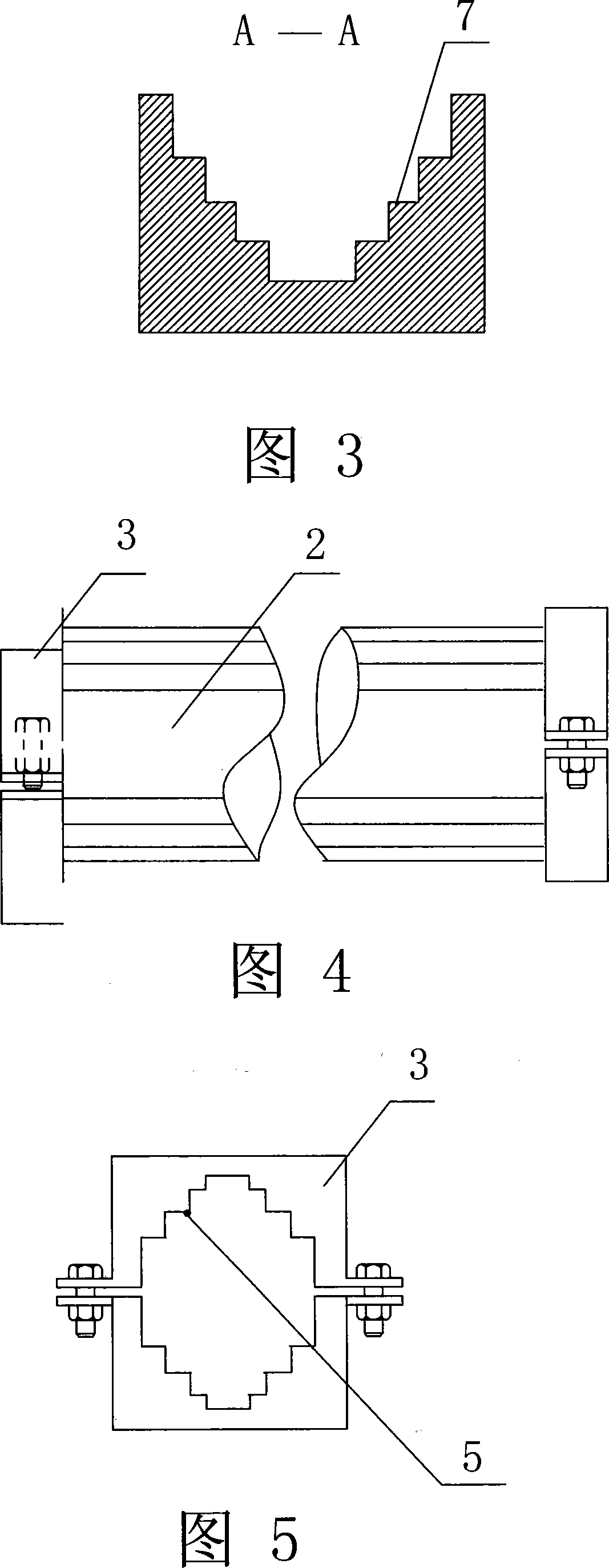

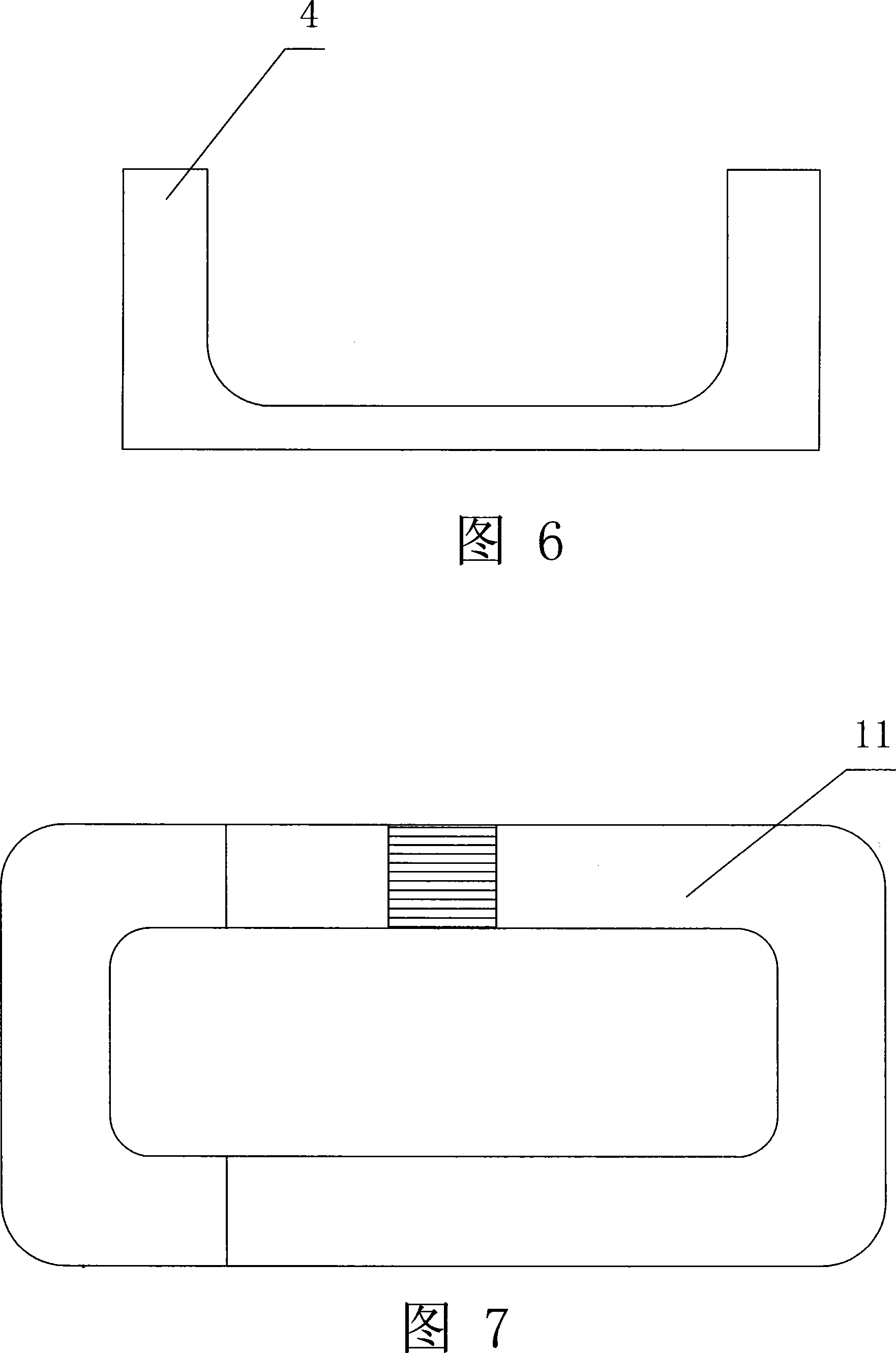

[0025] The manufacturing method of the C-shaped iron core of the voltage transformer is shown in Figure 1. Firstly, according to the expanded size of the C-shaped iron core 1, the entire silicon steel sheet is cut into a plurality of strip-shaped silicon steel sheets with different widths, which are classified according to different widths. According to the thickness of the cross-section of the C-shaped iron core 1 of different specifications, the number of strip-shaped pieces to be used is calculated, and the strip-shaped pieces are respectively placed in a groove 6 whose bottom shape is the same as the geometric shape of the side of the C-shaped iron core 1 , as shown in Figure 2-3, that is, the two inner surfaces of the groove 6 are symmetrically provided with a plurality of steps 7, and the strip-shaped silicon steel sheet moves from the center of the bottom of the groove 6 to the two inner surfaces in the direction of the strip-shaped sheet. The width is from large to smal...

Embodiment 2

[0028] Embodiment 2 is basically the same as Embodiment 1, except that the entire silicon steel sheet is cut into a plurality of strip-shaped silicon steel sheets of equal width, and the strip-shaped silicon steel sheets are placed in a groove 10 upright, as shown in Figure 9 , insert and fold tightly to form a strip lamination 8, and clamp the two ends of the strip lamination 8 with two clips 9 respectively, as shown in Figure 10, place the clamped strip lamination 8 on the U C-shaped iron core 11 is pressed on the mold, as shown in Figure 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com