Patents

Literature

93results about How to "Scientific and reasonable preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

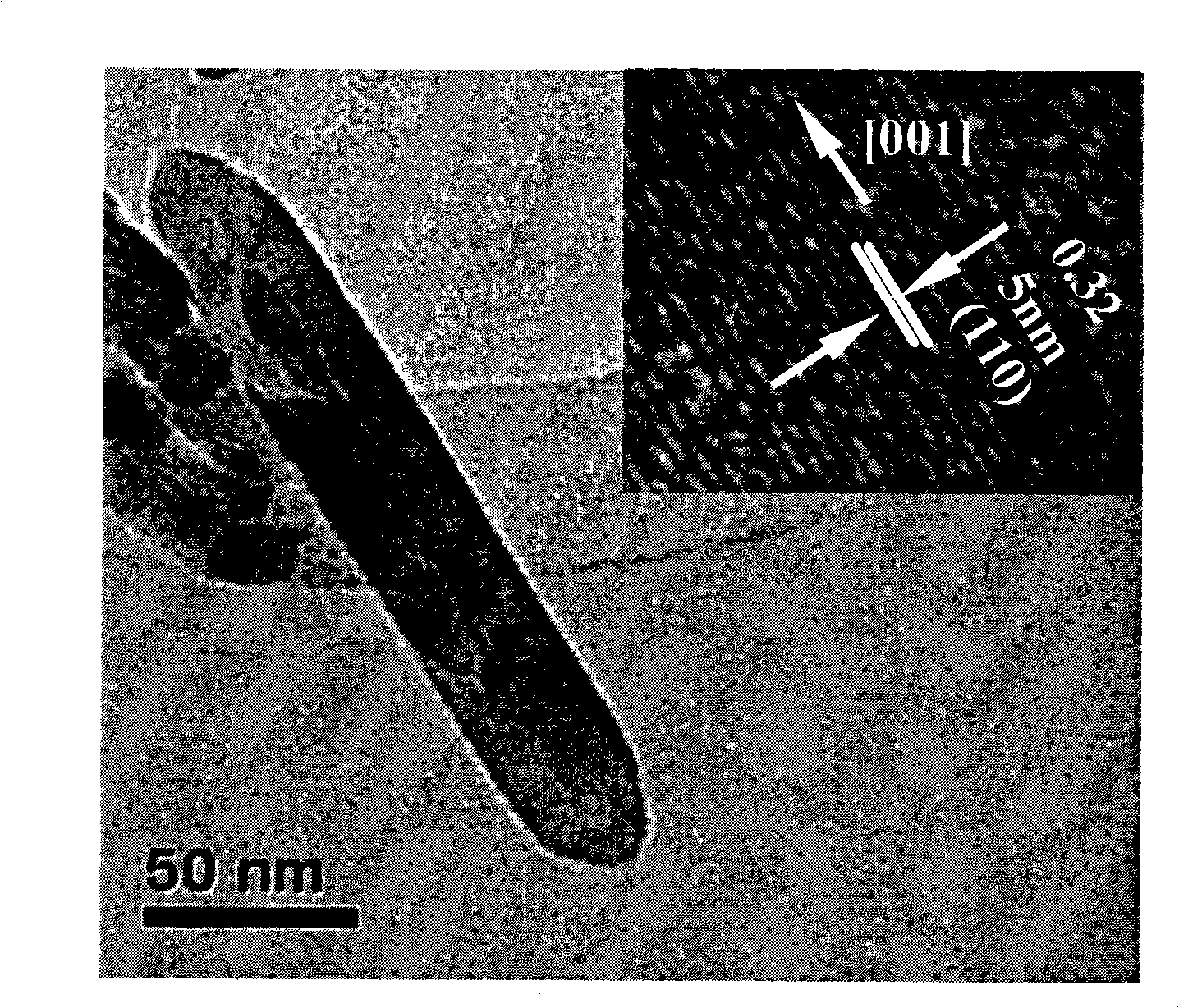

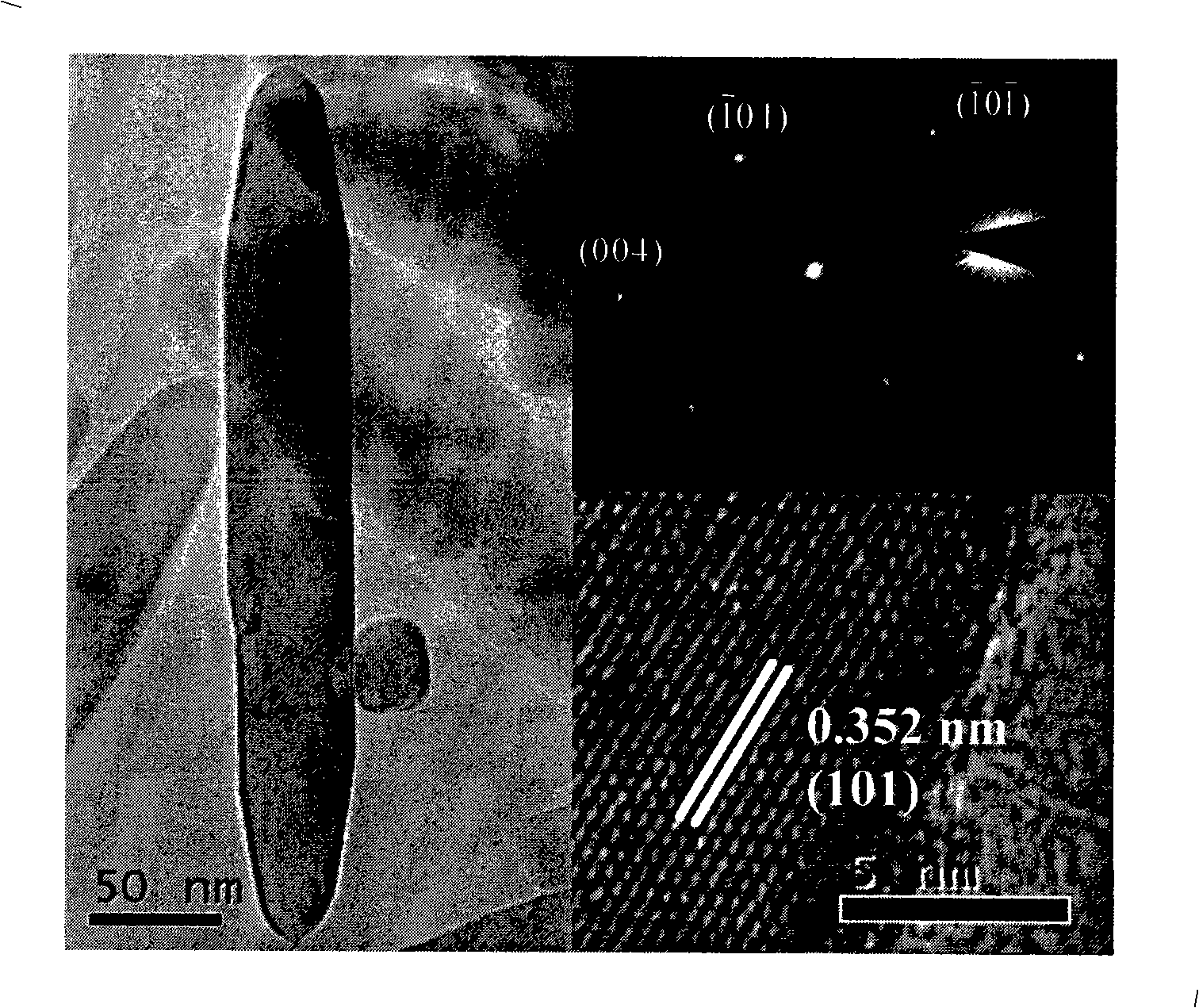

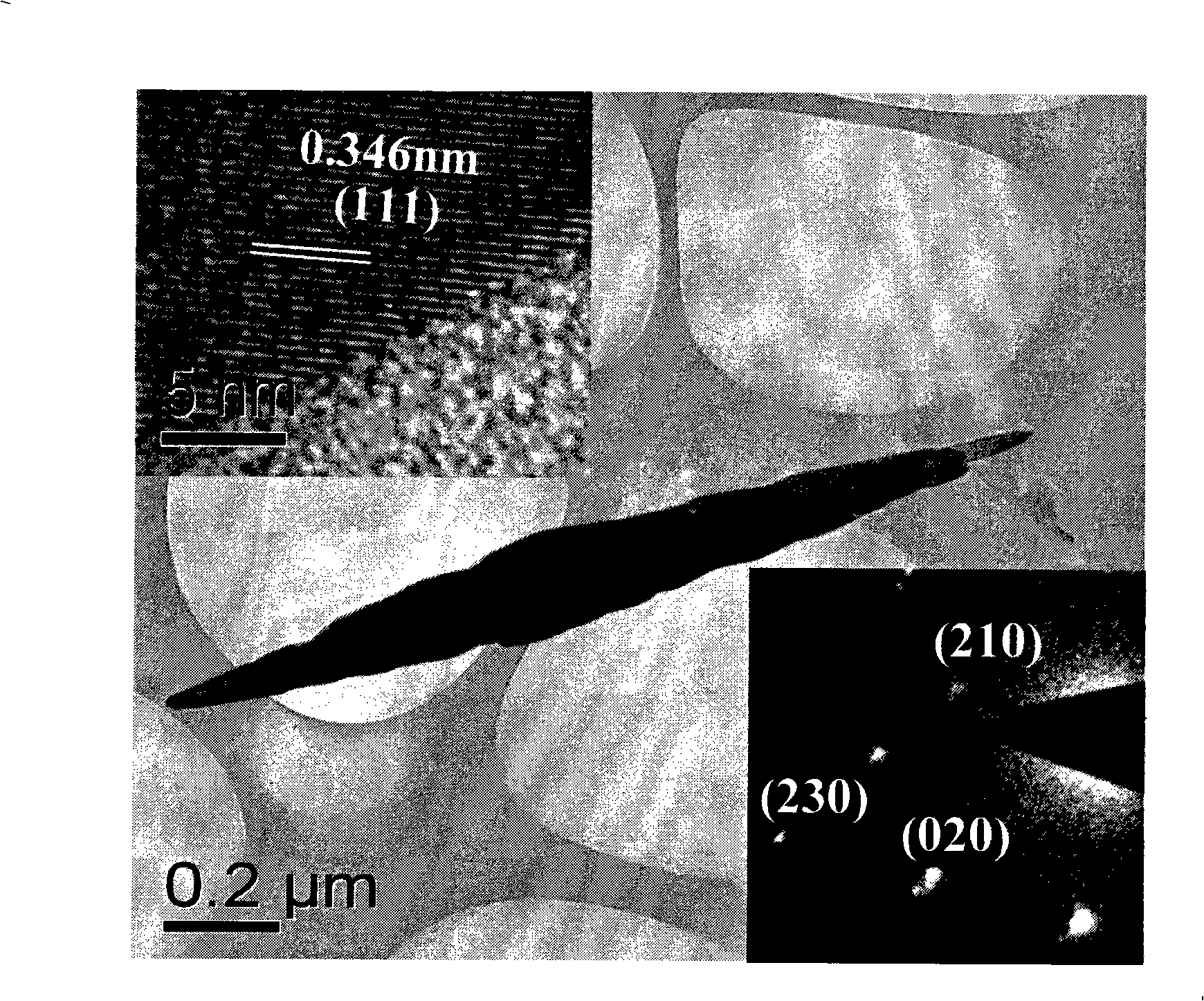

Method for controllable synthesis of pure phase anatase, red schorl, brookite titania nanorod

The invention provides a method for controllably synthesizing pure phase anatase, rutile, brookite titanium dioxide nano-rod. The pure phase anatase, rutile, brookite titanium dioxide nano-rod can be controllably synthesized by controlling the reaction condition of precursor prepared by titanium dioxide powder and alkali solution through a simple hydrothermal method. The method of the invention controllably synthesizes pure phase anatase, rutile, brookite titanium dioxide nano-rod through a simple hydrothermal method at a lower temperature and under a condition without adding any surfactants or templates and has advantages of simply operation, low cost, stable performance, high purity, obvious economic benefit and social benefit which can be synthesized in a large amount.

Owner:FUZHOU UNIV

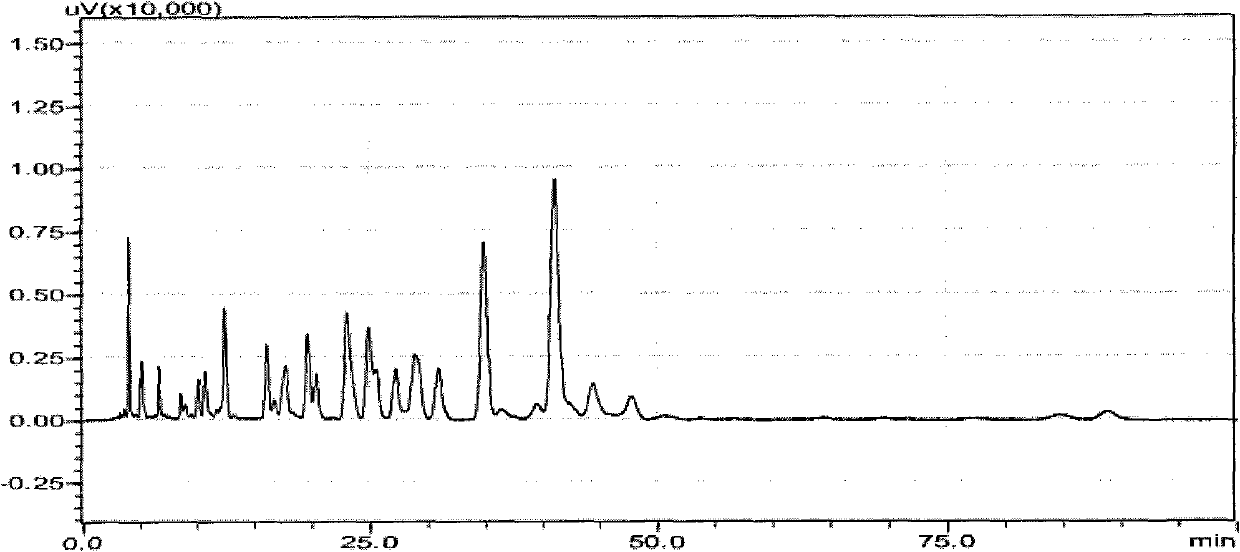

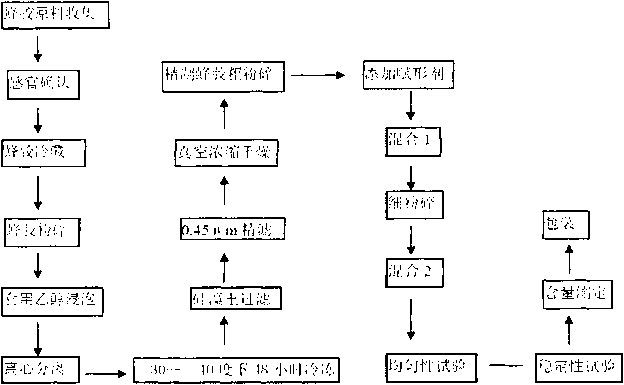

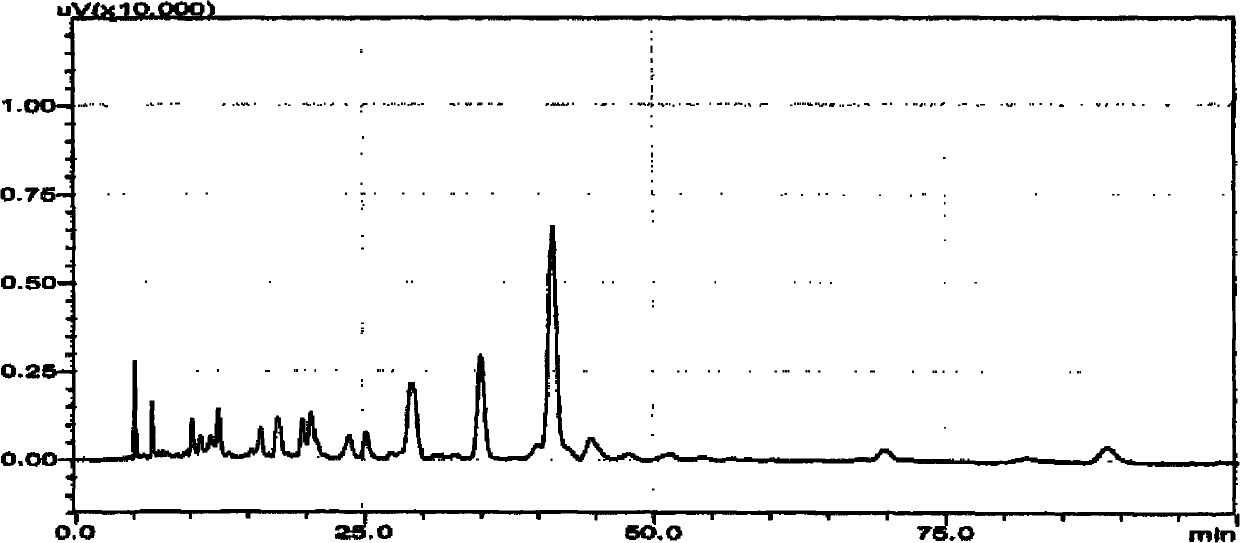

Method for preparing real substance sample for authentication of propolis liquid phase fingerprint

ActiveCN101957349AAnalysis method is simpleQuality improvementComponent separationWater bathsPropolis

The invention relates to a method for preparing a real substance sample for authentication of a propolis liquid phase fingerprint. At present, the mature method for authenticating poplar gum and propolis is unavailable. The method comprises the processes of preparing a propolis substance sample and a poplar gum substance sample. The process of preparing the propolis substance sample comprises thefollowing steps of: soaking the propolis in 95 percent edible ethanol; drying the refined propolis liquid in vacuum in a water bath at the temperature of 80 to 95 DEG C; and mixing the crushed refined propolis and an excipient, and sieving the mixture with an 80-mesh sieve to obtain the propolis substance sample. The process of preparing the poplar gum substance sample comprises the following steps of: heating polar-water mixed liquid to over 90 DEG C; pressing the liquid to obtain a polar liquid; after cooking the polar liquid, soaking the polar liquid in the 95 percent edible ethanol; drying the refined polar gum liquid in vacuum in the water bath at the temperature of 80 to 95 DEG C; and mixing the crushed refined polar gum liquid and the excipient, and sieving the mixture with the 80-mesh sieve to obtain the poplar gum substance sample. The method has the advantages of reasonable and scientific preparation, strong operability and application to effective authentication of the false propolis prepared from polar sprouts.

Owner:杭州蜂之语蜂业股份有限公司

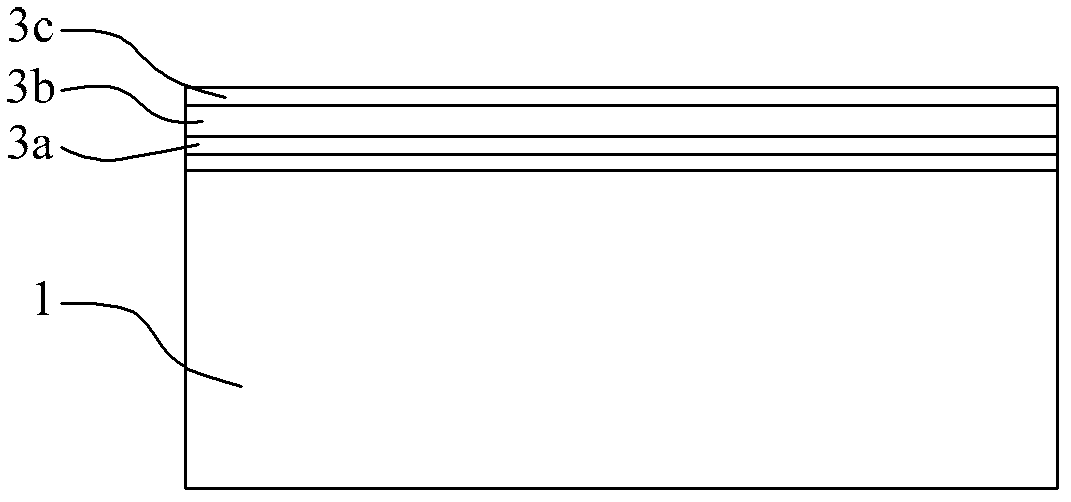

Liquid nozzle and manufacturing method thereof

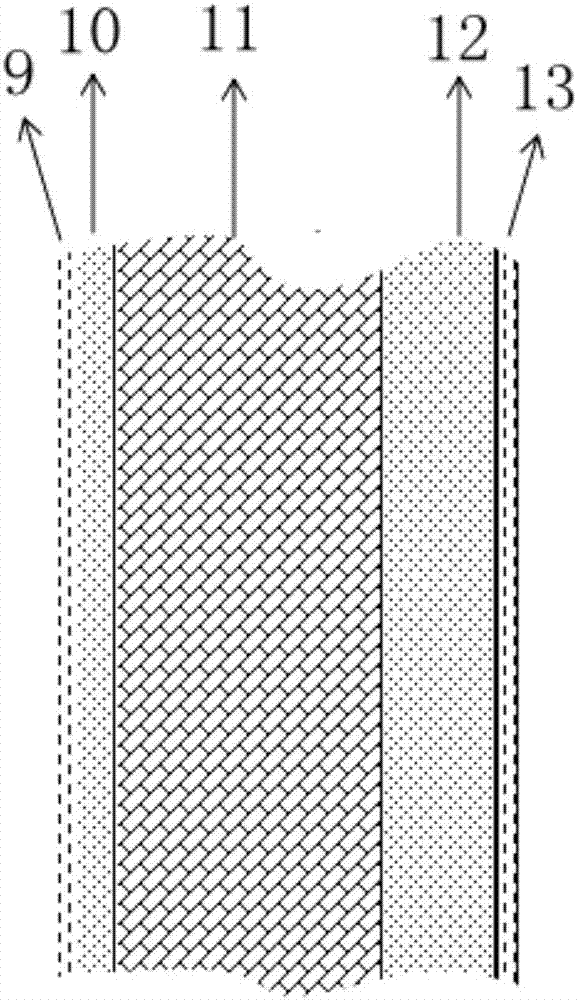

ActiveCN103072378AThe manufacturing process is scientific and reasonableImprove yieldPrintingThin layerNozzle

The invention provides a liquid nozzle and a manufacturing method thereof. The manufacturing method of the liquid nozzle comprises the following steps that an insulating material layer used as an oscillating plate is arranged on the common electrode surface of a piezoelectric element; a first thin layer made of optical imaging high molecular materials is arranged on the surface of the insulating material layer, and an area determined as a liquid cavity in the first thin layer is exposed for the first time; a second thin layer made of optical imaging high molecular materials is arranged on the surface of the exposed first thin layer, and an area determined as a liquid spraying hole in the second thin layer is exposed for the second time; and developing liquid is utilized to develop and remove unexposed materials from the first thin layer and the second thin layer, so as to form the liquid cavity and the liquid spraying hole. According to the liquid nozzle disclosed by the invention, integrated forming of the liquid cavity and the liquid nozzle is implemented through double exposure and one-time development, the strength of the liquid cavity and the rate of finished products are increased, and the liquid nozzle is favorable for improving the quality of printing equipment.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

Technological process for removing fine occluded foreignsubstance in molten steel

ActiveCN101323893AImprove purityEfficient removalProcess efficiency improvementSlagNon-metallic inclusions

The invention relates to an external refining technology of various micro-alloy steels and special steels, in particular to a technology for removing slag inclusions in molten steel. The technology of the invention comprises the steps as follows: a. the adjustment of an RH work position: the positions of a down pipe and a feed pipe of the RH are adjusted to ensure that the down pipe is positioned at the opposite side of the feed pipe; b. refining: after being transported to the RH work position, ladles are done with temperature measurement, sampling, vacuumizing, ingredient adjustment and clean circulation; c. input of compound spheres: after the refining, the compound spheres are put into the molten steel at the work position; d. continuous casting: after the compound spheres are put into the molten steel, the molten steel is then directly cast on a machine and the continuous casting adopts a whole-process protection casting. The technology of the invention can control the size and the quantity of the non-metallic inclusions in steel and the total oxygen amount to be 3ppm to 14ppm, the equivalent diameter of the impurities to be 0.5micron to 9micro and the average area of the impurities to be 0.002 percent to 0.008 percent, thus greatly improving the clearity of the molten steel and reducing the smelting cost.

Owner:ANGANG STEEL CO LTD

Technological process for removing small inclusions in secondary refining

ActiveCN101323894AScientific and reasonable preparationIncrease the probability of collisionProcess efficiency improvementCollision probabilitySlag

The invention relates to an external refining technology of various micro-alloy steels and special steels, in particular to a technology for removing slag inclusions in molten steel by the external refining technology. The technology of the invention comprises the steps as follows: a. molten steel is refined at LF, RH, VD or CAS-OB work position; b. a wire feeding technology is adopted to feed cored wires into the molten steel at the work positions; c. the molten steel is then directly cast on a machine after the wire feeding and the continuous casting adopts a whole-process protection casting. As the added cored wires have a scientific and reasonable prescription, when micro-air bubbles occur in the molten steel, the bubbles have high collision probability with the slag inclusions and fine slag drops have the function of wash heat and can also effectively remove the slag inclusions in the molten steel. The technology of the invention can control the size and the quantity of the non-metallic inclusions in steel and the total oxygen amount can be controlled to be 3ppm to 14ppm, the equivalent diameter of the impurities to be 0.5 micron to 9 micro and the average area of the impurities to be 0.002 percent to 0.008 percent, thus greatly improving the clearity of the molten steel and reducing the smelting cost.

Owner:ANGANG STEEL CO LTD

Cactus health care tea and its preparation method

The present invention relates to green beverage and is especially health cactus tea and its production process. Edible cactus as material is produced into the health cactus tea through cleaning, slicing, soaking, drying and frying or through cleaning, slicing, soaking, dewatering and stoving, and the product is sealed and packed. During the production, aweto, glossy ganoderma, wolfberry fruit, chrysanthemum, gingko leaf, American ginseng and other health Chinese medicinal materials may be added. The production process can keep the nutritive components of cactus, and the health cactus tea is verdure, and has pure taste, fragrance and obvious health functions.

Owner:朱胜一

Technique for outside-stove refining dephosphorization

The invention relates to an external refining process for various microalloy steel and special steel, in particular to a process method for external refining desulphurization, which is the preferred process method for desulphurization during the refining processes of various microalloy steel or special steel. The process comprises the following steps of: a. deoxidation: molten steel is firstly subjected to deoxidation treatment to realize that alpha[O] is less than or equal to 0.0003 percent; b. the adjustment of a RH station: the positions of a RH descending tube and a blanking tube are adjusted to ensure that the RH descending tube is positioned at the opposite side of the blanking tube; c. the adding of compound spheres: after a ladle is transported to the RH station, the compound spheres are added into the molten steel at the RH station after temperature measurement sampling, vacuum pumping, clean recycle and refining are finished; and d. continuous casting: the continuous casting adopts the whole-process protection. Proven by application, the process has strong desulphurization ability with a desulphurization rate between 60 and 90 percent, can realize the refining desulphurization of the molten steel until the content of sulfur is lower than 0.0010 percent, greatly improves the purity of the molten steel, and reduces smelting cost.

Owner:ANGANG STEEL CO LTD

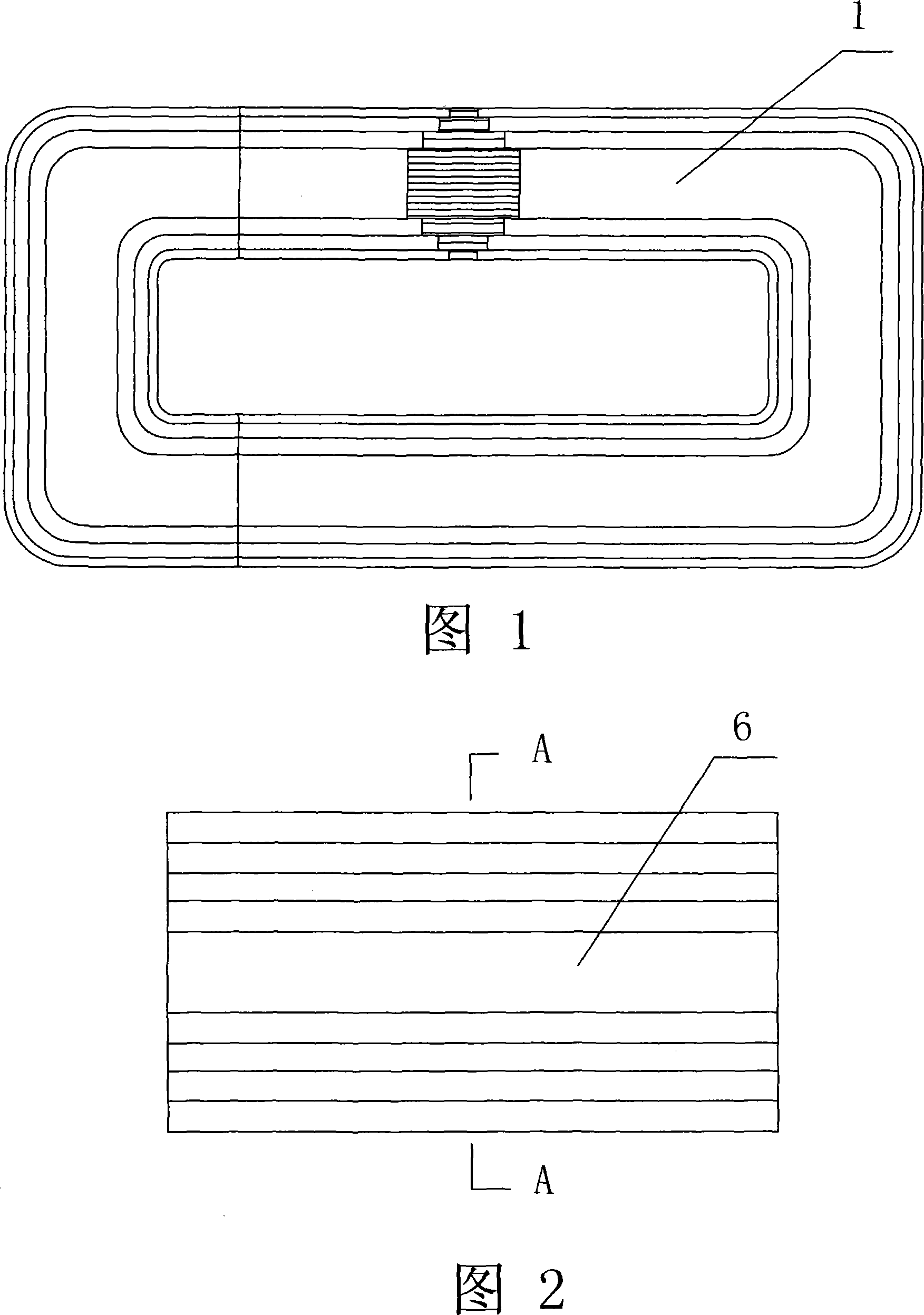

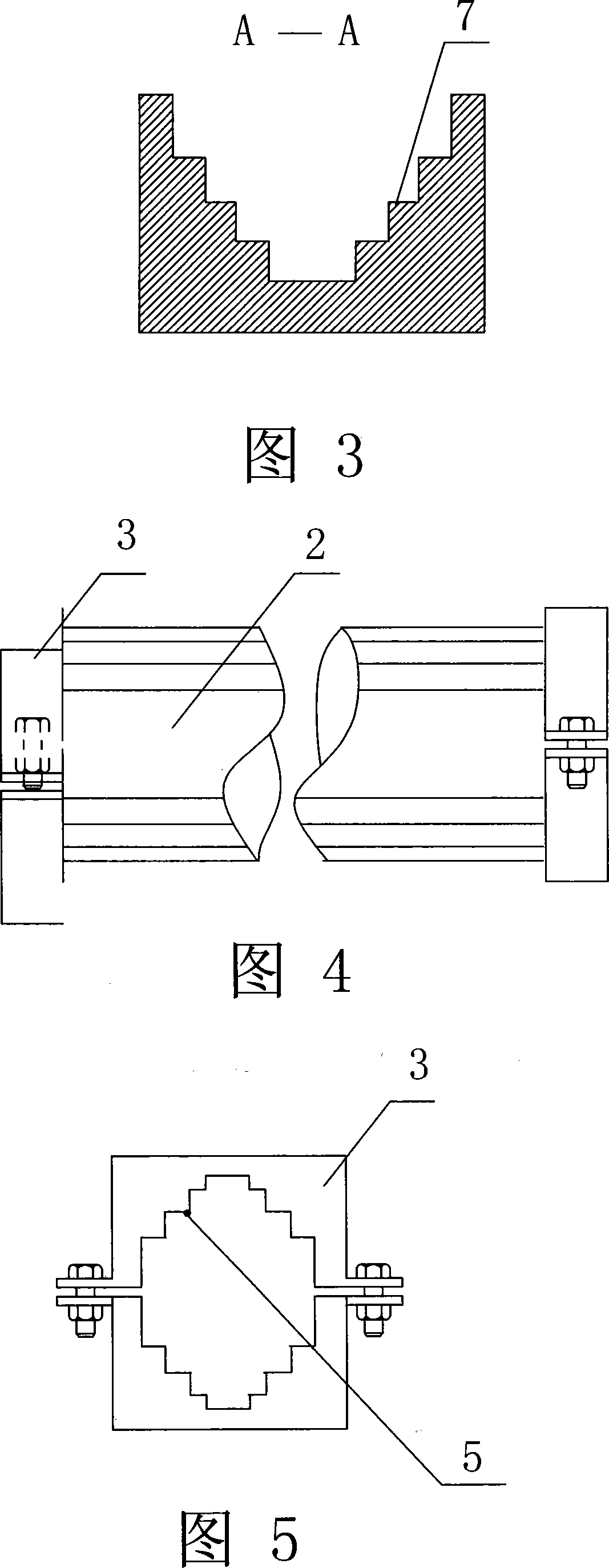

Making method of C-type ironic core of voltage mutual inductor

ActiveCN101086915AIncrease interlayer compactnessSolve the real problemTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerEngineering

The preparing method of voltage transformer C type iron core is based on voltage transformer C type iron core; the silicon steel disc is cut into bar-type piece, the bar-type piece is placed in a groove; two ends of the bar-type piece are blocked by two clips, bar-type piece blocked is placed on U type mould, up and down, left and right are pressed to C type iron core at the same time, two ends of the C type iron core are spot welded, hot processed, dipped, two C type iron core ends are cut, rubbed. The invention not only can save time and save work, increase efficiency, increase compactness, increase quality of product, standard flow production can be realized, and output can be increased greatly. More importantly the leftover material of silicon steel disc can be used to decrease spending. The invention is scientific, possesses advantages and performance of the same product, it possesses extreme practicality; and fits for usage of various departments.

Owner:大连普能科技发展有限公司

Zro2 thermal barrier coating prepared by plasma spraying method

InactiveCN103343312AScientific and reasonable preparationReaction is easy to controlMolten spray coatingEfficient propulsion technologiesPhysical chemistryThermal barrier coating

The invention relates to a Zro2 thermal barrier coating prepared by a plasma spraying method. Firstly, stabile nano-zirconia powder with large specific surface areas can be prepared through using ZrO(NO3)2 as a zirconium source and adding epoxypropane, and then the <{EN0}>Zro2 thermal barrier coating can be prepared through adding a proper amount of Lu2O3, In2O3, Al2O3 and TiO2 on the basis of the prepared stabile nano-zirconia powder with the large specific surface areas. The prepared coating is good in stability and relatively high in corrosion resistance.

Owner:启东市天汾电动工具技术创新中心

Expansion-resistant graphene fiber nano building material and preparation technology thereof

The invention discloses an expansion-resistant graphene fiber nano building material and a preparation technology thereof. The expansion-resistant graphene fiber nano building material comprises the following raw materials in parts by weight: 80-90 parts of an ethylene-vinyl acetate copolymer, 40-50 parts of high-density polyethylene, 20-30 parts of a nano active agent, 2-8 parts of a plasticizer and the like. According to the expansion-resistant graphene fiber nano building material and the preparation technology thereof, provided by the invention, added nitrile rubber modified phenolic resin is mixed with raw materials to form a mixture, the mixture is cured when heated, and under the action of methylene decomposed by urotropin, the molten resin quickly changes from a linear structure into a non-molten three-dimensional structure; by improving mechanical properties, the expansion-resistant graphene fiber nano building material has high temperature resistance and low expansion; structurally, fiber membrane layers with different diameters and porosities are prepared, nanographene among bonding layers improves the porosity and the specific surface area of a composite adsorption membrane and enhances the efficacy; through adoption of asphalt-based carbon fiber, mechanical properties of the expansion-resistant graphene fiber nano building material is enhanced, so that the expansion-resistant graphene fiber nano building material can greatly adsorb and remove harmful gas and dust substances in exhaust gas.

Owner:SUZHOU RUI TE JIE CHEM PROD CO LTD

Banyan tea and preparation thereof

InactiveCN1423955AKeep natural and pureFully preserve active nutrientsTea substituesSpray dryingChemistry

A banyan tea is prepared from leaves of banyan tree and longan tree through washing, fumigating, cooling, dewatering, parch drying and breaking, or extracting, concentrating, and spray drying. Its can be canned, or made into instant particles, capsules, etc.

Owner:苏少宁 +1

Technological process for removing fine occluded foreignsubstance in molten steel

ActiveCN101323895AImprove purityEfficient removalProcess efficiency improvementSlagNon-metallic inclusions

The invention relates to an external refining technology of various micro-alloy steels and special steels, in particular to a technology for removing slag inclusions in molten steel. The technology of the invention comprises the steps: a. molten steel is refined at LF, RH, VD or CAS-OB work position; b. a powder spraying technology is adopted to spray powder into the molten steel at the work positions; c. the molten steel is then directly cast on a machine after the powder spraying and the continuous casting adopts a whole-process protection casting. As the added powder has a scientific and reasonable prescription, when micro-air bubbles occur in the molten steel, the bubbles have high collision probability with the slag inclusions and fine slag drops have the function of wash heat and can also effectively remove the slag inclusions in the molten steel. The technology of the invention can control the size and the quantity of the non-metallic inclusions in steel and the total oxygen amount to be 3ppm to 14ppm, the equivalent diameter of the impurities to be 0.5micron to 9micro and the average area of the impurities to be 0.002 percent to 0.008 percent, thus greatly improving the clearity of the molten steel and reducing the smelting cost.

Owner:ANGANG STEEL CO LTD

ZrO2 thermal barrier coating prepared by electron-beam physical vapor desorption

InactiveCN103225062AIncreased molten salt corrosion performanceScientific and reasonable preparationVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionPhysical chemistry

The invention relates to a ZrO2 thermal barrier coating prepared by electron-beam physical vapor desorption. A preparation method of the ZrO2 thermal barrier coating comprises the following steps of: firstly, preparing stable nanometer zirconia powder with a large specific surface area by adopting ZrO(NO3)2 as a zirconium source and dropwise adding epoxypropane, and then preparing the ZrO2 thermal barrier coating by adding a right amount of Lu2O3, In2O3, A12O3 and TiO2 on the basis of the prepared stable nanometer zirconia powder with the large specific surface area. The prepared coating has good stability and high corrosion-resistant performance.

Owner:STATE GRID ZHEJIANG LONGYOU POWER SUPPLY +1

Technological process for removing fine occluded foreignsubstance in molten steel

ActiveCN101323895BImprove purityEfficient removalProcess efficiency improvementSlagNon-metallic inclusions

Owner:ANGANG STEEL CO LTD

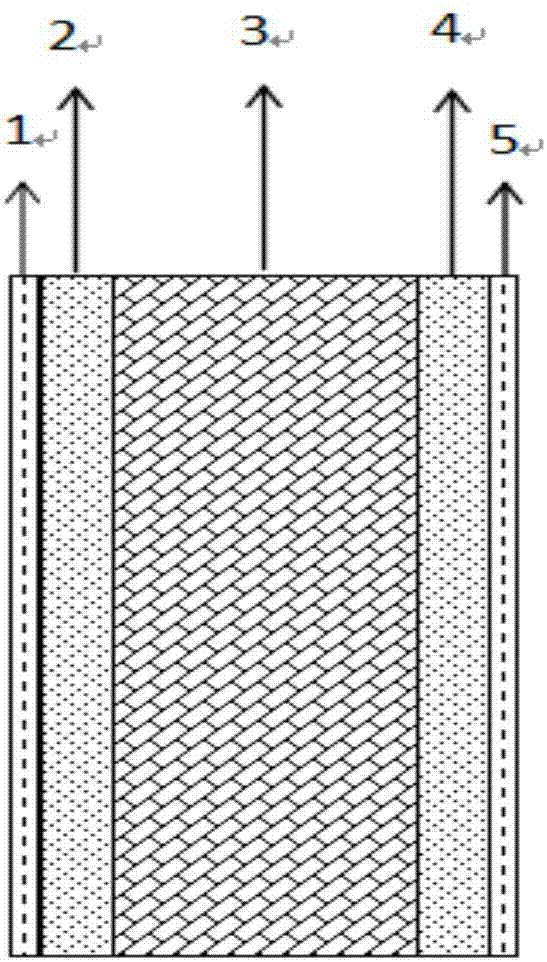

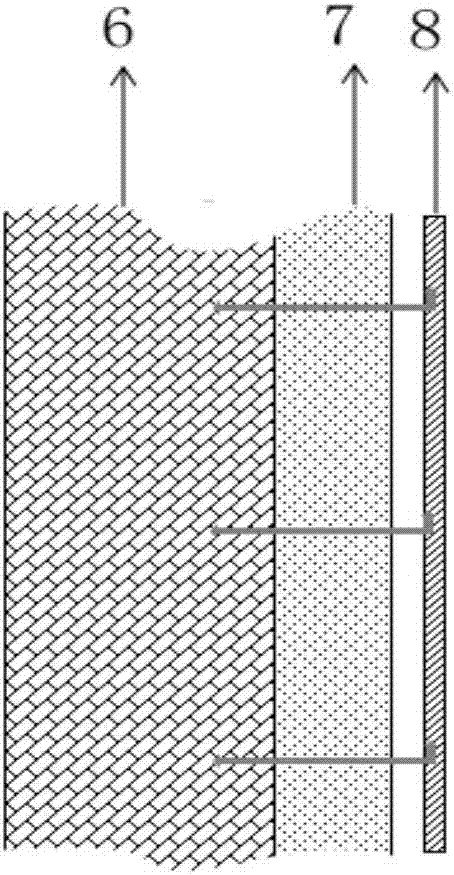

Inorganic mineral fiber spray rock mortar and using method thereof

The invention belongs to the field of wall building construction inside and outside heat insulation, sound insulation and fireproof materials, and relates to inorganic mineral fiber spray rock mortar and a using method thereof. The inorganic mineral fiber spray rock mortar is prepared from, by weight, 60-65% of inorganic mineral fiber, 15-20% of fibrous sepiolite, 0.1-0.5% of hydroxypropyl methyl cellulose, 2% of redispersible latex powder, 0.5% of water repellent and 10-16% of Portland cement. The using method includes the steps that water is added into the inorganic mineral fiber spray rock mortar according to the weight ratio, the mixture is stirred into paste, and the paste is put into a sprayer for spraying; a wall is directly sprayed, inorganic mineral fiber spray rock mortar layers are formed at the two sides of the wall until the layers reach the design thickness; the surfaces of the inorganic mineral fiber spray rock mortar layers are decorated; compared with an existing inorganic mineral fiber spray heat insulation wall construction, A1-grade fire resistance is higher, sturdiness and weather fastness are better, and the defect that an existing inorganic mineral fiber spray heat insulation material has the single purpose of heat insulation in an outer curtain wall and a stone wall is solved.

Owner:JILIN LONGYANG BUILDING MATERIALS CO LTD +1

A preparing method of an oil-proof modified composite environment-friendly rubber base material

A preparing method of an oil-proof modified composite environment-friendly rubber base material is disclosed. The method includes preparing graphene oxide having a high oxidation degree, modifying the graphene oxide and preparing the oil-proof modified composite environment-friendly rubber base material. The base material adopts pitch-based carbon fibers to enhance mechanical properties, and can greatly adsorb and clean harmful gas and dust compounds in tail gas. Prepared MC nylon has an advantage of good comprehensive properties. The base material can be used for works under various bad conditions. Added components can effectively ensure no easy combustion of a protected material, and do not generate gas harmful to human bodies during combustion at overhigh temperatures. Compared with hydrotalcite in the market at present, the base material has obvious advantages in the fields of high-temperature resistance, fire protection and flame retardance.

Owner:常熟市瑞思知识产权服务有限公司

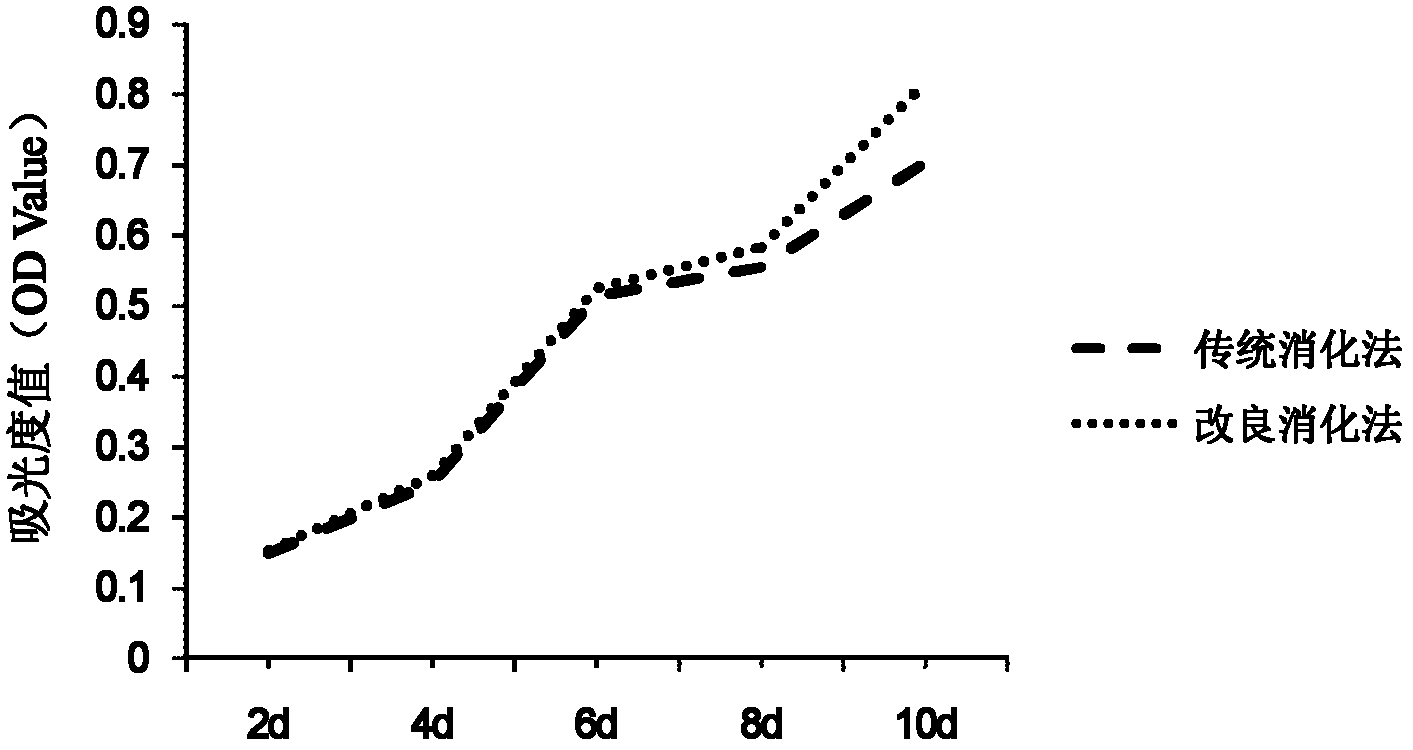

Method for performing in-vitro culture to bovine preadipocytes

InactiveCN102559589AScientific and reasonable preparationAdvanced and simple technologySkeletal/connective tissue cellsDiseaseMaterial resources

The invention discloses a method for performing in-vitro culture to bovine preadipocytes, belonging to the technical field of cell and tissue engineering. The method is based on the traditional subculture method, a tissue homogenizer is utilized and combines with the collagenase I culture medium to treat the fatty tissue, a DMEM (Dulbecco's Modified Eagle Medium) / F12 culture solution containing fetal bovine serum is used to perform in-vitro culture to bovine preadipocytes, and a new model of the in-vitro culture of bovine preadipocytes is successfully built. The technology is advanced and simple, the preparation of the culture medium is scientific and reasonable, manpower and material resources are saved, and the treatment time of the test sample is greatly shortened; the obtained cell morphology is best, the RNA (Ribonucleic Acid) culture and extraction efficiency is maximum, the preadipocyte culture method is convenient and efficient in a long term and lays the foundation for the gene expression and protein expression and the signal pathway in the later intensive study of the proliferation and differentiation process of preadipocytes; and a new idea and a new method are provided to regulate body fatness deposition of beef cow and prevent diseases in the perinatal period and lactation peak period of milk cow, etc.

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI

Method for preparing zirconium oxide thermal barrier coating by spraying process

ActiveCN103290352AEasy to cleanLoose powderMolten spray coatingEfficient propulsion technologiesCorrosive substanceGreen environment

The invention relates to a method for preparing a zirconium oxide thermal barrier coating by a spraying process, which comprises the following steps: preparing large-specific-area stable nano zirconium oxide powder by a green environment-friendly process; and on the basis of the prepared large-specific-area stable nano zirconium oxide powder, adding proper amounts of Lu2O3, In2O3, Al2O3 and TiO2 to prepare the ZrO2 thermal barrier coating. The prepared coating has the advantages of high stability and high corrosion resistance.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

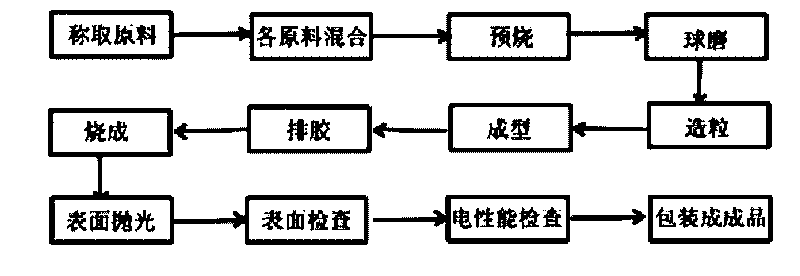

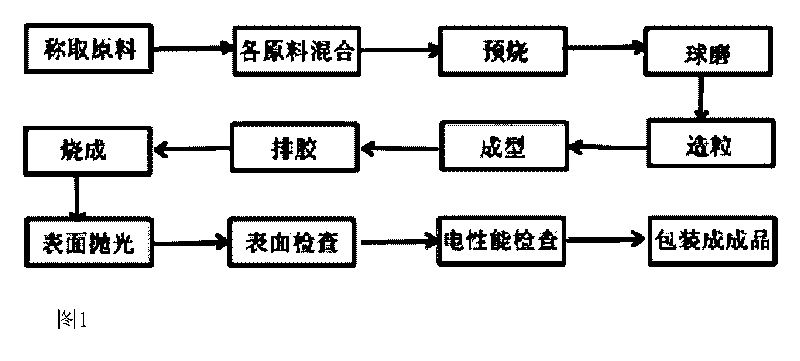

Novel high performance magnetic material for energy-saving lamps

ActiveCN101694801AImprove luminous performanceLow costTransformersInorganic material magnetismState of artMaterials science

The invention provides a novel high performance magnetic material for energy-saving lamps, and belongs to the technical field of magnetic materials for energy-saving lamps. The novel high performance magnetic material for the energy-saving lamps solves the problem of magnet ring existence in the prior art. The novel high performance magnetic material for the energy-saving lamps of the invention is added with additives on the basis of Fe2O3-MnO-ZnO ternary prescription, and the additives are Co2O3, CuO and SrCo3. The preparation process of the magnetic material of the invention comprises the following steps: mixing raw materials according to raw material proportion, then, pre-sintering, ball-grinding, pelleting, shaping, discharging glue, sintering and polishing surfaces. The raw material prescription and preparation process of the invention are scientific and rational, and the prepared magnetic material is used to manufacture magnetic rings, and has excellent performance, and energy-saving lamps adopting the magnetic ring have the advantages of long service life, low cost, excellent light emitting effect and the like.

Owner:福建省福晶磁性材料有限公司 +1

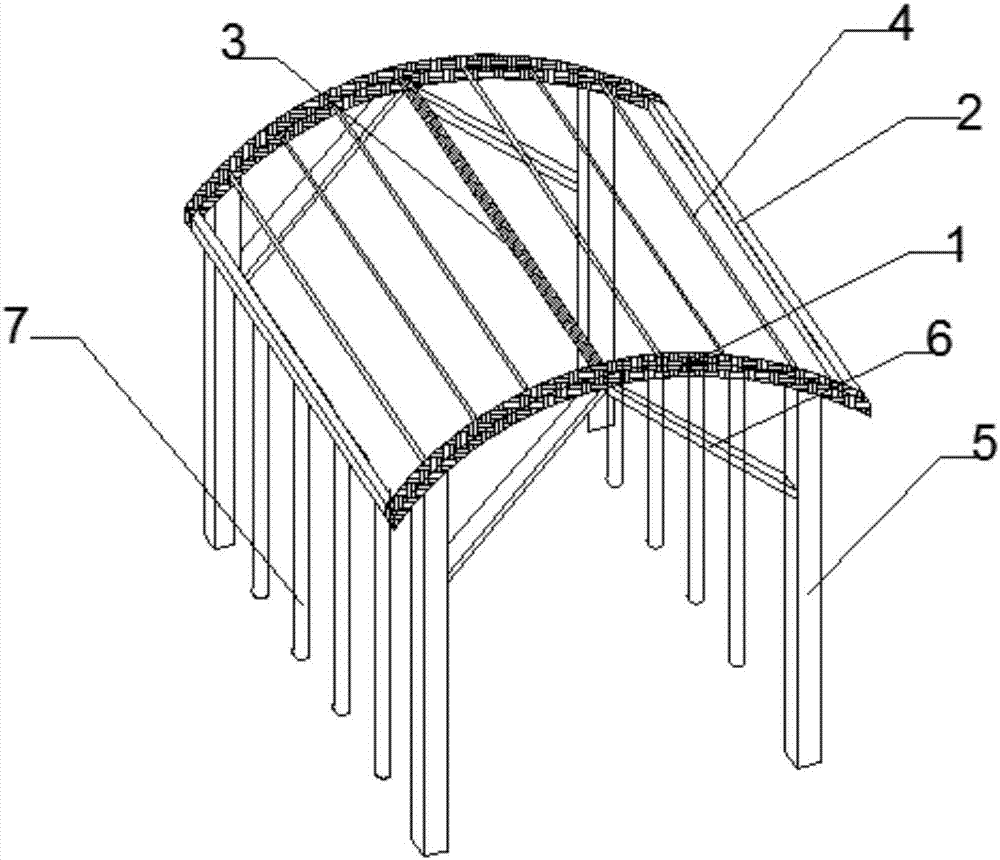

Grape culture method and culture shelf thereof

ActiveCN107466568AImprove disease resistanceProtection result rateFertilising methodsCultivating equipmentsVitis viniferaTrace element

The invention discloses a grape culture method and a culture shelf thereof. The method comprises the steps of preparing seedling bed soil, building a culture shelf, selecting seedlings and planting, fixing seedlings, fertilizing, shaping and trimming, and managing flowers and fruits. The culture shelf comprises arch rods, a drain tank, cross rods, supporting rods, upright posts, fixing rods and climbing rods. The culture method has the beneficial effects that the seedling bed soil is scientific and reasonable in preparation, is rich in organic matters, contains multiple amino acids and trace elements, and can be used for efficiently regulating the soil structure and activating soil, improving disease resistance of grapes and controlling the growing process of grapes; excellent seedlings are selected, and targeted topdressing is carried out in different growing stages, and therefore, effective absorption of grapes for nutrition can be ensured, reasonable trimming, pinching and picking fruits provide a high-quality space environment for grape growth, the fruit rate of grapes is better protected, and yield is increased.

Owner:杨玲

Method for preparing corrosion-resistant zirconium oxide thermal barrier coating

ActiveCN103290353AEasy to cleanLoose powderMolten spray coatingVacuum evaporation coatingCorrosion resistantCorrosive substance

The invention relates to a method for preparing a corrosion-resistant zirconium oxide thermal barrier coating. The method comprises the following steps of: firstly, preparing stable nano zirconium oxide powder with a large specific area by adopting an environment-friendly method; and then adding an appropriate amount of Lu2O3, In2O3, Al2O3 and TiO2 on the basis of the prepared stable nano zirconium oxide powder with the large specific area so as to prepare a ZrO2 thermal barrier coating. The prepared coating is good in stability and has relatively high corrosion resistance.

Owner:南通市电梯部件业商会

Anti-aging graphene nanometer environment-friendly modified plastic color master batch and preparation technology thereof

The invention discloses an anti-aging graphene nanometer environment-friendly modified plastic color master batch and a preparation technology thereof. According to the anti-aging graphene nanometer environment-friendly modified plastic color master batch and the preparation technology thereof provided by the invention, fiber films with different diameters and pores are manufactured structurally, and the nanometer graphene between layers is combined for improving the pore and specific area of the compound adsorption film, so that the effect is enhanced. According to the invention, pitch-based carbon fiber is adopted for enhancing the mechanical properties of materials and thus harmful gas and dust substances in tail gas can be greatly absorbed and cleared.

Owner:苏州泰如新材料科技有限公司

Vitamin dripping pill and its preparing method

ActiveCN1943563AIncrease the dosage form of clinical useMeet the needs of clinical disease prevention and treatmentMetabolism disorderPill deliveryMedicineDrugs preparations

The invention related to vitamin drop pills and its preparation process and belongs to technical field of drug preparation. Its formula consists of vitamin, base material for drop pills, anti-oxidant, surface active agent, coating material, etc. its process is first prepared vitamin into farine with fineness above 150 mesh. Take base material of formula and soluble after heating, adding vitamin farine and relevant auxiliary material, mixing into even dispersible solution, dropping into condenser and becoming pills, preparing into pills with coating or non-coating. Each pill containing vitamin 0.05mg-30mg and its weight is 10mg-100mg.

Owner:AOLING BODA MEDICINE SCI & TECH DEV BEIJING

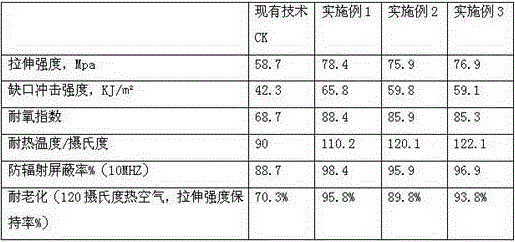

Method for preparing graphene polyvinyl chloride resin compound material

The invention discloses a method for preparing a graphene polyvinyl chloride resin compound material. The method comprises the following steps: firstly, synthesizing graphite oxide by utilizing graphite, and preparing a graphene oxide solution with stable dispersibility from the graphite oxide; then, reacting the graphene oxide solution with copper lysine, adding sodium borohydride for primary reduction; removing residual copper in the system through sulfonation reaction and hydrazine hydrate reduction, filtering, washing and drying to obtain functional graphene; dissolving the functional graphene in acetone, performing ultrasonic treatment, adding dispersant, initiator and surfactant, stirring and mixing in the presence of nitrogen; and adding chloroethylene monomer, magnetically stirringto react, and pouring the product into a die for curing and molding after the reaction is completed. According to the preparation method, the preparation process is scientific and reasonable, the dispersibility of the material is effectively improved by functionalizing graphene, the compound performance of graphene and high-molecular resin can be promoted, and the tensile strength and impact resistance of the material can be enhanced.

Owner:TAIZHOU UNIV

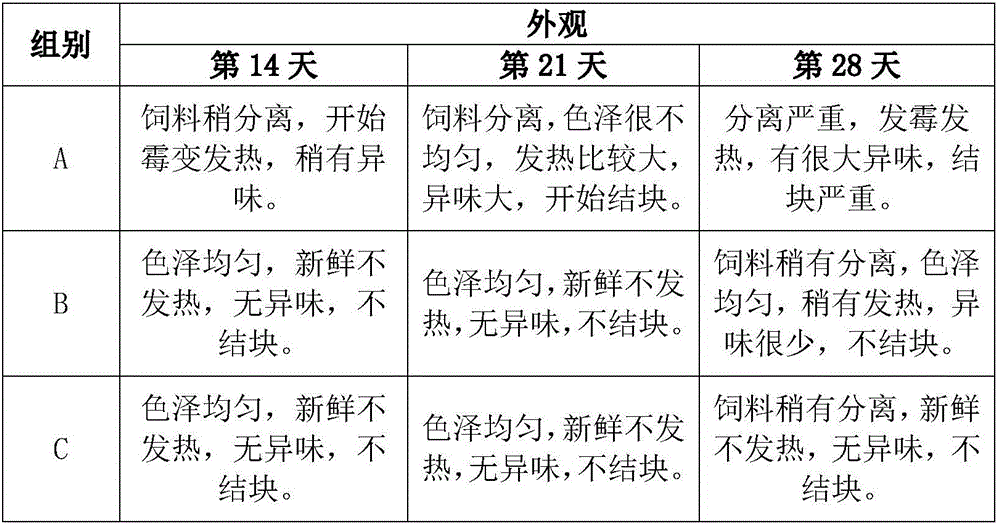

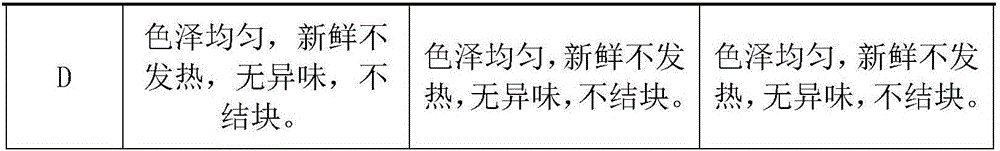

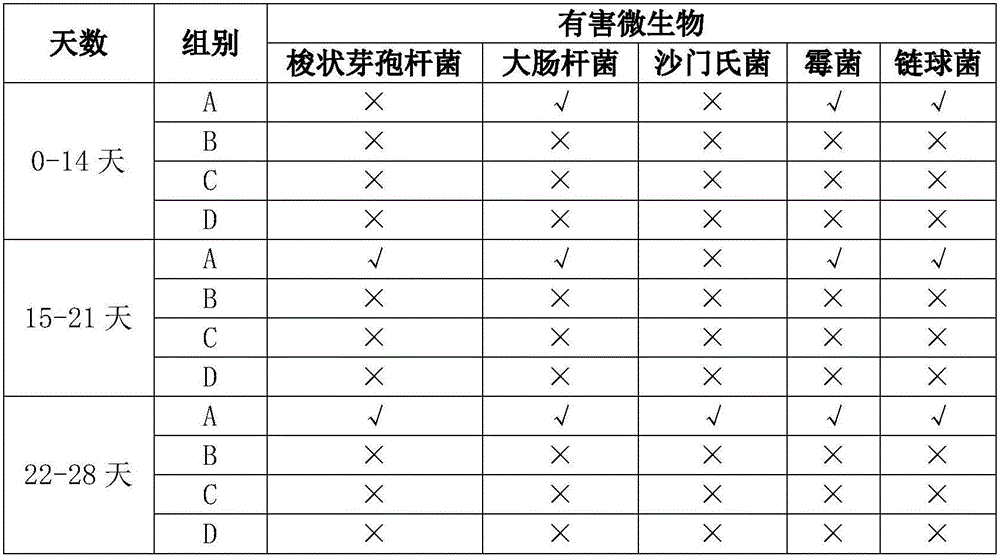

Nutritional preservative for total mixed ration and preparation method for nutritional preservative

InactiveCN106615750AImprove palatabilityEliminate oxidation reactionAnimal feeding stuffAccessory food factorsVitamin CSide effect

The invention belongs to the technical field of mixed feed additives, and particularly relates to a nutritional preservative for a total mixed ration and a preparation method for the nutritional preservative. The nutritional preservative for the total mixed ration is prepared from the following raw materials: lactobacillus plantarum powder, sodium diacetate, phytic acid, cinnamic acid, grape polyphenols, tea polyphenols, soybean oligopeptides, ginkgo leaves extract, allicin, herba inulae extract, yellow sweet clover extract and vitamin C. The nutritional preservative for the total mixed ration contains multiple natural antibacterial and anti-oxidation components, comprises environment-friendly components, and is free of drug resistance and toxic or side effects, and is used for replacing a large dose of a preservative or antibiotics required to be used at present, bacteria can be effectively killed, mildews can be effectively proofed, the respiratory decay of feeds can be suppressed, the yield of an animal product such as meat and milk can be improved, and the quality of the animal product can be improved; stepwise water addition is adopted in the preparation method, so that a uniformly dissolved preservative can be obtained more easily, and the effective utilization rate of the raw materials is increased.

Owner:SHANDONG JIANYUAN BIOTECHNOLOGY CO LTD

Method for preparing ZrO2 thermal barrier coating in plasma sprayed coating way

InactiveCN103290351AScientific and reasonable preparationReaction is easy to controlMolten spray coatingEfficient propulsion technologiesPhysical chemistryPlasma sprayed coating

The invention relates to a method for preparing a ZrO2 thermal barrier coating in a plasma sprayed coating way. The method comprises the following steps of: preparing stable nano-zirconia powder with a large specific surface area by a way of adopting ZrO(NO3)2 as a zirconium source and dropping epoxypropane; then adding proper Lu2O3, In2O3, Al2O3 and TiO2 based on the prepared stable nano-zirconia powder with the large specific surface area to prepare the ZrO2 thermal barrier coating. The prepared coating is high in stability and relatively high in corrosion resistance.

Owner:启东市天汾电动工具技术创新中心

Writing brush cleaning agent and preparation method

InactiveCN106566707AReduce surface tensionImprove decontamination effectInorganic/elemental detergent compounding agentsAmpholytes/electroneutral surface-active compoundsCocamidopropyl betaineChemistry

The invention relates to a writing brush cleaning agent and a preparation method and belongs to the technical field of cleaning agents. The writing brush cleaning agent and the preparation method are used for achieving the aims of effectively cleaning writing tips of goat-hair writing brushes and facilitating reuse. The technical scheme of the invention is as follows: the writing brush cleaning agent is prepared from ingredients in percentage by mass: sodium dodecyl sulfonate, polyoxyethylene lauryl ether, cocamidopropyl betaine, sodium citrate, tripolyphosphoric acid, sodium phosphate and the like. The preparation method comprises the steps of carrying out weighing, carrying out mixing, carrying out storage and carrying out packaging. The writing brush cleaning agent is prepared from a surfactant and various auxiliaries and adjuvants, so that the cleaning effect is improved. The preparation is simple and convenient. The writing brush cleaning agent has been used, and a good effect is achieved.

Owner:邹贝尔

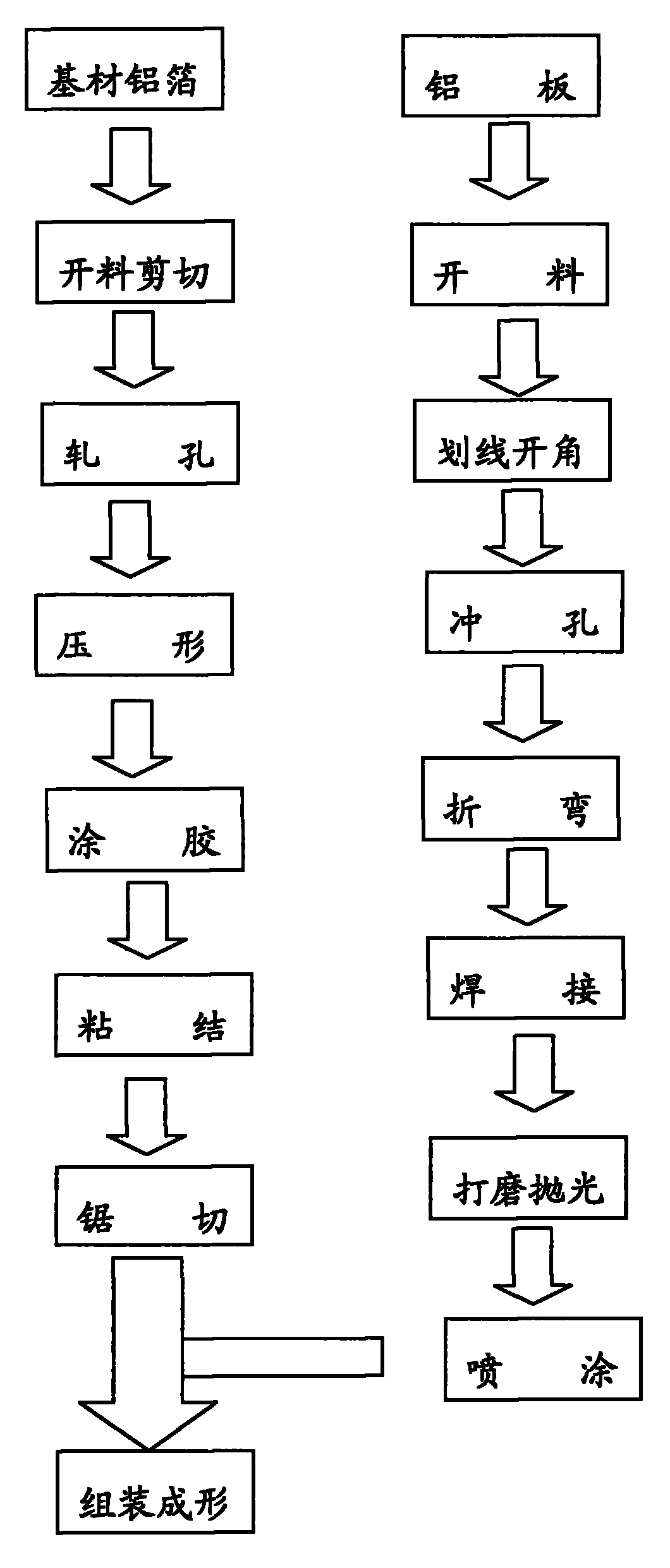

Novel micropore aluminum foil sound absorption acoustic screen

InactiveCN103397607AThe idea is clear and novelSimple and fast to makeNoise reduction constructionPunchingAluminum foil

The invention discloses a novel micropore aluminum foil sound absorption acoustic screen and relates to the technical field of building material decoration products. By adopting the key technology of 'using ultra-thin aluminum foil as a substrate micropore sound absorption structure', the manufacturing method comprises the following steps: the substrate aluminum foil is subjected to cutting, shearing, pricking, swaging, gluing, bonding and sawing to be manufactured into micropore sound absorption aluminum foil for use; an aluminum plate is subjected to cutting, scribing, angle opening, punching, bending, welding, polishing and spraying to be manufactured into an acoustic screen body for use; the micropore sound absorption aluminum foil and the acoustic screen body are assembled together to be manufactured into the finished product of the novel micropore aluminum foil sound absorption acoustic screen. The novel micropore aluminum foil sound absorption acoustic screen is used for sound absorption and insulation, and is ingenious in conception, reasonable in structure, good in sound absorption and insulation effect, resistant to impact, safe, reliable, retardant to flames, durable, convenient to install, use and maintain, attractive and elegant as a whole, easy to manufacture, low in cost, wide in application range, and beneficial to popularization and application.

Owner:唐海浩

Technological process for removing small inclusions in secondary refining

ActiveCN100582249CImprove purityEfficient removalProcess efficiency improvementSlagNon-metallic inclusions

The invention relates to an external refining technology of various micro-alloy steels and special steels, in particular to a technology for removing slag inclusions in molten steel by the external refining technology. The technology of the invention comprises the steps as follows: a. molten steel is refined at LF, RH, VD or CAS-OB work position; b. a wire feeding technology is adopted to feed cored wires into the molten steel at the work positions; c. the molten steel is then directly cast on a machine after the wire feeding and the continuous casting adopts a whole-process protection casting. As the added cored wires have a scientific and reasonable prescription, when micro-air bubbles occur in the molten steel, the bubbles have high collision probability with the slag inclusions and fine slag drops have the function of wash heat and can also effectively remove the slag inclusions in the molten steel. The technology of the invention can control the size and the quantity of the non-metallic inclusions in steel and the total oxygen amount can be controlled to be 3ppm to 14ppm, the equivalent diameter of the impurities to be 0.5 micron to 9 micro and the average area of the impurities to be 0.002 percent to 0.008 percent, thus greatly improving the clearity of the molten steel and reducing the smelting cost.

Owner:ANGANG STEEL CO LTD

Method for differentiating fat cells by oriented inducing chick embryo primordial germcell

InactiveCN1935988AScientific and reasonable preparationAdvanced and simple technologySkeletal/connective tissue cellsDiseaseDexamethasone

The invention relates to the method used to directionally induce chick embryo primordial germ cell to differentiate into fat cell. The adopted inducer includes inducer I and II which are respectively formed by 90% DMEM, 10% FBS, 5.5*10-5 beta-mercaptoethanol, 1*10-6mol / L dexamethasone, 10mg / L insulin, 5*10-4mol / L 3-isobutyl-1-methylxanthine, and 90% DMEM, 10% FBS, 5.5*10-5 beta-mercaptoethanol, 10mg / L. The invention has the advantages of simple technology, scientific and reasonable inducer and basic medium, convenient operation, strong repeatability. And it can provide new source for cell substituting therapy and tissue therapy, even organ transplantation.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com