A preparing method of an oil-proof modified composite environment-friendly rubber base material

An environmentally friendly rubber and modification technology, which is applied in the field of preparation of MC nylon/modified graphene oxide nanocomposites, can solve the problems of reduced toughness and reduced strength, and achieve a reasonable and scientific preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

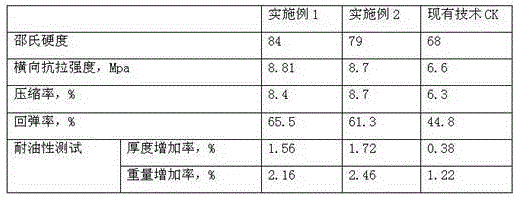

Examples

Embodiment 1

[0024] In an ice-salt bath, add 30ml of concentrated sulfuric acid to a three-neck flask containing 1g of graphite (325 mesh), stir the mixture at -15°C for a certain period of time for 12 hours, then stir at 0°C for 5 hours, then slowly add 2g potassium permanganate, heat up to 35°C, after reacting for a certain period of time, add deionized water, then heat up to 90°C, and finally add H 2 o 2 Until the product turns golden yellow to obtain a graphite oxide solution, add 0.2g CTAB to the product, the graphite oxide will quickly settle out in the solution, filter, wash, and vacuum dry at 50°C for 24 hours to obtain a modified graphite oxide modified with CTAB. Graphene.

Embodiment 2

[0026] In an ice-salt bath, add 30ml of concentrated sulfuric acid to a three-neck flask containing 1g of graphite (325 mesh), stir the mixture at -10°C for a certain period of time for 10 hours, then stir at 0°C for 3 hours, then slowly add 2.3g potassium permanganate, heat up to 35°C, after reacting for a certain period of time, add deionized water, then heat up to 90°C, and finally add H 2 o 2 Until the product turns golden yellow to obtain a graphite oxide solution, add 0.3g CTAB to the product, the graphite oxide will quickly settle out in the solution, filter, wash, and vacuum dry at 50°C for 24 hours to obtain a modified graphite oxide modified with CTAB. Graphene.

Embodiment 3

[0028] In an ice-salt bath, add 30ml of concentrated sulfuric acid to a three-neck flask containing 1g of graphite (325 mesh), stir the mixture at -20°C for a certain period of time for 12 hours, then stir at 0°C for 6 hours, then slowly add 3g potassium permanganate, heat up to 35°C, after reacting for a certain period of time, add deionized water, then heat up to 90°C, and finally add H 2 o 2 Until the product turns golden yellow to obtain a graphite oxide solution, add 0.1g CTAB to the product, the graphite oxide will quickly settle out in the solution, filter, wash, and vacuum dry at 50°C for 24 hours to obtain a modified graphite oxide modified with CTAB. Graphene.

[0029] b. Preparation of graphite oxide with a high degree of oxidation;

[0030] B. adopt cetyltrimethylammonium bromide to modify the graphite oxide obtained in step a, and obtain graphene oxide by ultrasonic to the obtained modified graphite oxide;

[0031] c. Preparation of MC nylon / modified graphene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com