Liquid nozzle and manufacturing method thereof

A technology of a liquid nozzle and a manufacturing method, applied in printing and other directions, can solve the problems of low quality of liquid spray, high manufacturing cost, low yield of liquid nozzles, etc., and achieve scientific and reasonable manufacturing process, improve yield, and avoid binders. the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation of the present invention will be described in detail below in conjunction with the drawings and specific examples to help readers better understand the essence and beneficial effects of the present invention, but it should not be construed as any limitation on the scope of the present invention.

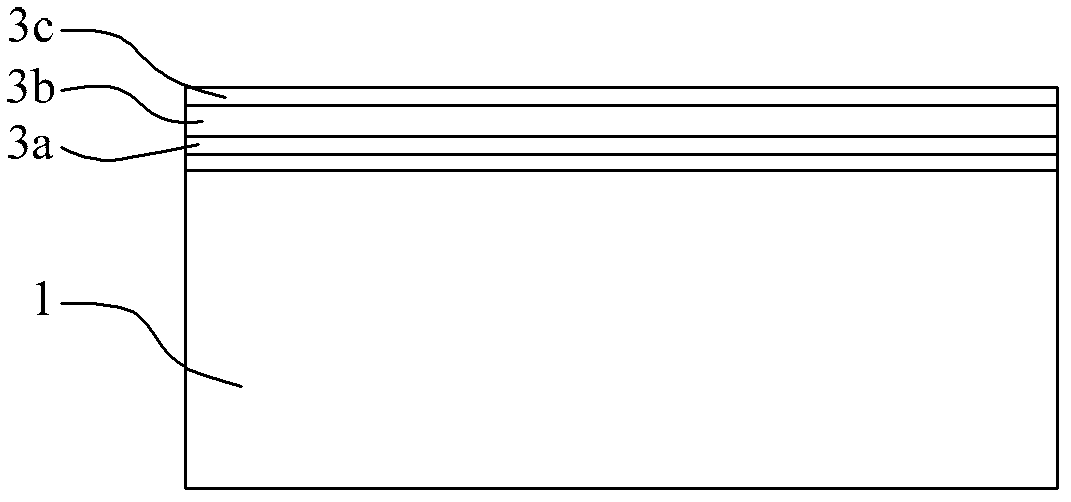

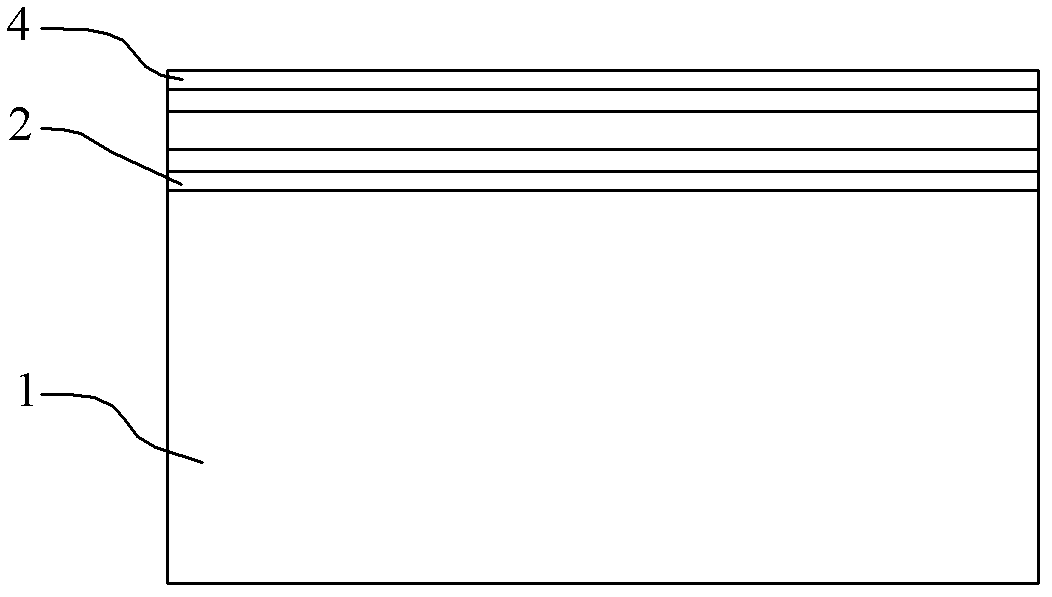

[0035] Please refer to Figure 1-10 , the manufacturing process of this embodiment is as follows:

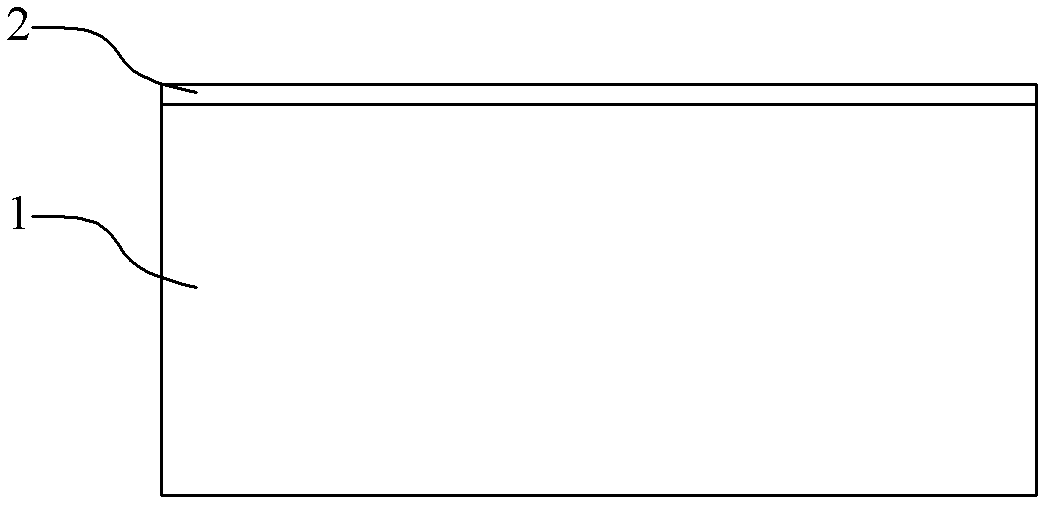

[0036] 1. Form a peeling layer 2 on the base 1

[0037] The material selection and the formation mode of the base 1 and the peeling layer 2 are conventional methods, such as figure 1 shown;

[0038] As the base 1, it is best to choose a material with good light transmission and heat resistance, so as to reduce the energy attenuation during the light irradiation process, and facilitate the subsequent peeling of the peeling layer. The transmittance of the base to irradiated light is preferably at least 10%, more preferably at least 50%. If the transmittance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com