Novel high performance magnetic material for energy-saving lamps

A technology of magnetic materials and energy-saving lamps, which is applied in the direction of inorganic material magnetism, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of short life of energy-saving lamps, and achieve consistent and stable performance, significant economic benefits, and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Each component in the raw material formula of magnetic materials, Fe 2 o 3 -MnO-ZnO according to the mol ratio is:

[0029] Fe 2 o 3 : 53 copies

[0030] MnO: 34 parts

[0031] ZnO: 9 parts;

[0032] Additives: according to the weight of the total material: Co 2 o 3 0.1%; CuO0.15%; SrCO 3 0.015%.

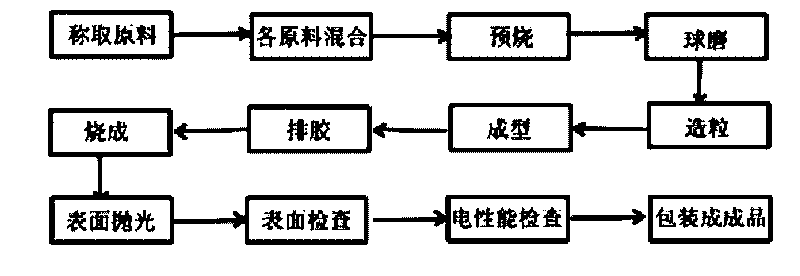

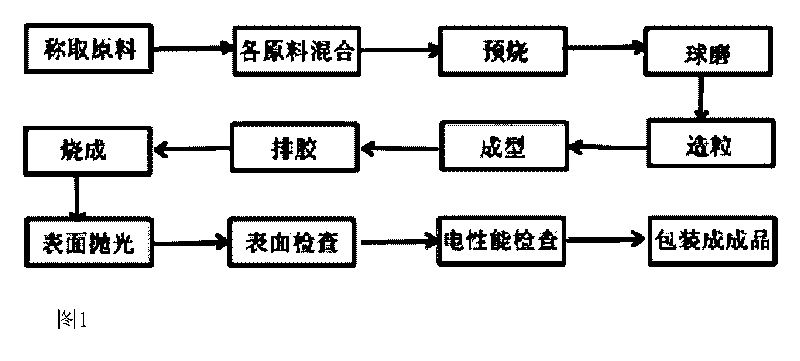

[0033] The specific preparation process of the magnetic material is as follows;

[0034] (1) According to the ratio of raw materials, each raw material is mixed;

[0035] (2) Pre-burning: Pre-burning at 1000°C for 2 hours;

[0036] (3) ball milling: ball milling with a sand mill for 4 hours;

[0037] (4) Granulation: granulation with a spray granulator;

[0038] (5) Forming: Forming with a rotary press;

[0039] (6) Degumming: Bake at 910°C for 2 hours for degumming;

[0040] (7) Firing: Firing in a nitrogen kiln or bell furnace, the firing temperature is 1355°C, and the sintering time is 5 hours;

[0041] (8) Surface polishing: Polish the product with a vibra...

Embodiment 2

[0044] Each component in the raw material formula of magnetic materials, Fe 2 o 3 -MnO-ZnO according to the mol ratio is:

[0045] Fe 2 o 3 : 54 copies

[0046] MnO: 38 parts

[0047] ZnO: 12 parts;

[0048] Additives: according to the weight of the total material: Co 2 o 3 0.2%; CuO0.2%; SrCO 3 0.02%.

[0049] The specific preparation process of the magnetic material is as follows;

[0050] (1) According to the ratio of raw materials, each raw material is mixed;

[0051] (2) Pre-burning: Pre-burning at 1000°C for 2 hours;

[0052] (3) ball milling: ball milling with a sand mill for 4 hours;

[0053] (4) Granulation: granulation with a spray granulator;

[0054] (5) Forming: Forming with a rotary press;

[0055] (6) Degumming: Bake at 910°C for 2 hours for degumming;

[0056] (7) Firing: Firing in a nitrogen kiln or bell furnace, the firing temperature is 1355°C, and the sintering time is 5 hours;

[0057] (8) Surface polishing: Polish the product with a vibrat...

Embodiment 3

[0060] Each component in the raw material formula of magnetic materials, Fe 2 o 3 -MnO-ZnO according to the mol ratio is:

[0061] Fe 2 o 3 : 53.5 parts

[0062] MnO: 35 parts

[0063] ZnO: 10 parts;

[0064] Additives: according to the weight of the total material: Co 2 o 3 0.15%; CuO0.18%; SrCO 3 0.018%.

[0065] The specific preparation process of the magnetic material is as follows;

[0066](1) Mixing each raw material according to the ratio of raw materials;

[0067] (2) Pre-burning: Pre-burning at 1000°C for 2 hours;

[0068] (3) ball milling: ball milling with a sand mill for 4 hours;

[0069] (4) Granulation: granulation with a spray granulator;

[0070] (5) Forming: Forming with a rotary press;

[0071] (6) Degumming: Bake at 910°C for 2 hours for degumming;

[0072] (7) Firing: Firing in a nitrogen kiln or a bell furnace, the firing temperature is 1355°C, and the sintering time is 5 hours;

[0073] (8) Surface polishing: Polish the product with a vibr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com